Single Crank Press (100-600 Tons), APF Series

Mechanical Press Machine | Metal Stamping Process | 100 - 600 Metric Tons Capacity

The APF series single crank press is a metal forming press with an incredible press capacity from 100-600 tons. This stamping press is produced in 8 different models with varying stamping capacities. The punching machine is so precise that it is categorized in the JIS 1 class, making it suitable for continuous sheet metal processing.

1. Advanced European, American and Japanese technologies/functional structure including a CAE dynamic simulation optimized design

2. High-standard metal forming processes of such key parts as gears and axles through hard chrome plating/nitriding/grinding

3. High-standard fabrication processing of such key parts as gears and axles through hard chrome plating/nitriding/grinding

4. High-level configurations of high-performance controllers/drive parts/electromagnetic clutches/steam-driven elements and bearings

5. Technical grade international metalworking machine and inspection of machine index

6. High-response multi-functional superposition expansion/high-quality industrial control processor

7. High-memory module/individual design franchised software compilation

8. High-compatibility multi-axial variable speed drive/ onboard automation equipment expansion

9. Intelligent interface/high frequency real-time control/Ethernet & USB interface configuration

1.Oil pressure overload protection device

2.Electric slide adjust device

3.Die height indicator (unit: 0.1 mm)

4.Slider and mold balancing device

5.Rotary cam switch

6.Crank angle indicator

7.Circulation centralization lubrication device

8.Electromagnetic stroke counter

9.Over-run safety device

10.Programmable controller

11.Mobile T-type operating floor

12.Air source connector

13.Independent electric control cabinet

14.Maintenance tool and tool box

1.Die cushion

2.Upper slide feeding device

3.Die Light

4.Main motor inversion device

5.Photo-electric safety device

6.Safety groove and safety plug

7.Preset counter (6 digits)

8.Loading inspection device

9.Misfeed detection device

10.Frequency converter

11.Basic bolt and soleplate

12.Anti-vibration device

13.Safety shelf and safety ladder

14.Power socket

15.Quick die change device

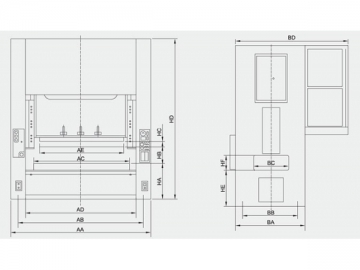

| Name | Unit | APF-110 | APF-160 | APF-200 | APF-260 | APF-300 | APF-400 | APF-500 | APF-600 | ||||||

| Model | V | H | V | H | V | H | V H | V | H | V | H | V | V | ||

| Capacity | ton | 110 | 160 | 200 | 260 | 300 | 400 | 500 | 600 | ||||||

| Rated tonnage point | mm | 6 | 3 | 6 | 3 | 6 | 3 | 7 | 3.5 | 7 | 3.5 | 9 | 4.5 | 10 | 13 |

| Stroke | mm | 180 | 80 | 200 | 90 | 200 | 100 | 250 | 150 | 300 | 170 | 300 | 200 | 250 | 250 |

| Variable speed | s.p.m | 30-60 | 60-90 | 20-50 | 40-70 | 20-50 | 50-70 | 20-40 | 40-50 | 20-40 | 35-50 | 15-25 | 20-35 | 20-30 | 15-20 |

| Constant speed | s.p.m | 50 | 35 | 35 | 30 | 30 | 20 | 20 | 20 | ||||||

| Die height | mm | 360 | 410 | 460 | 510 | 460 | 510 | 500 | 550 | 550 | 615 | 550 | 600 | 550 | 550 |

| Slide adjustment | mm | 80 | 100 | 110 | 120 | 120 | 150 | 120 | 120 | ||||||

| Slide area | mm | 1000×550×70 | 1100×600×90 | 1200×650×90 | 1300×700×100 | 1400×800×110 | 1500×850×110 | 1400×800 | 1400×1200 | ||||||

| Bolster area | mm | 1100×600×110 | 1200×800×140 | 1300×820×160 | 1400×840×180 | 1500×950×200 | 1600×1000×200 | 1500×1000 | 1700×1300 | ||||||

| Side opening | mm | 700×500 | 850×600 | 880×650 | 900×700 | 1000×750 | 1000×750 | 900×800 | 1000×900 | ||||||

| Main motor | kwx p | 11×4 | 15×4 | 18×4 | 22×4 | 30×4 | 40×4 | 55×4 | 75×4 | ||||||

| Slide adjusting motor | kwx p | 0.4×4 | 0.75×4 | 0.75×4 | 1.5×4 | 1.5×4 | 2.2×4 | 3×4 | 3×4 | ||||||

| Air pressure | kg/cm2 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| Presses precision | GB/T23280-2009 ( JIS 1 class) | ||||||||||||||

Download PDF