H Frame Double Crank Press (160-600 Tons), APE Series

H Frame Power Press | Stamping Press for Automotive Parts | 160 - 600 Metric Tons Capacity

Our APE series H frame double crank presses are precision presses that feature incredibly fast operation with all of the safety features that you look for in a press machine. The slide adjustment mechanism is accurate to within 0.1mm. The crank presses are suitable for sheet metal cutting, punching, bending and other sheet meal forming processes for the production of automotive parts, household products and electronics components. The punching machine features a spacious desk pate with an opening that allows for single and multiple project operation. It also allows the machine to be connected to an automatic transfer device or servo driven robot for automatic feeding.

1. Super rigid steel frame

The metal forming press is designed to resist deflection and vibration caused by the immense forces produced during stamping. The reinforced frame allows the machine to produce accurate pressings with a longer die life, even at full tonnage loads.

2. High precision

The H frame double crank press adopts a transmission mechanism to maximize precision for the entire lifetime of the machine. The crankshaft, gears, gear shafts, and other friction parts are hardening with a heat treatment and are further processed by grinding to increase wear resistance and balance.

3. Automatic processing

This stamping press for automotive parts features a closed electrical circuit design that can be paired with a variety of automated devices.

4. Stable and safe

These motor stator stamping presses are built to meet all relevant safety standards. They adopt a highly sensitive and reliable clutch/brake and top duplex magnetic valve, as well as overload protection devices to guarantee precision and safety of the slide during running and stopping.

1.Dry clutch brake

2.Standard operating system

3.Model choice/switching/adjusting/one stroke/continuous operating

4.Oil pressure overload protection device

5.Over-run safety device

6.Duplex magnetic valve

7.Misfeed detection device

8.Electric slider adjusting device

9.Die height indicator (unit: 0.1 mm)

10.Electric lubricating device

11.Accumulative counter (6 digits)

12.Preset counter (6 digits)

13.Maintenance counter (6 digits)

14.Life counter (6 digits)

15.Electronic rotary cam switch (6 connections)

16.Air jetting device 1/2" primary circuit

17.Air source connector 1/2" secondary circuit

18.Error detection socket

19.Power socket (only apply to single-phase 110V power)

1.Wet clutch brake

2.Die cushion device

3.Vs variable-speed motor

4.Touch-screen device

5.Photo-electric safety device

6.Upper slider feeding device

7.Main motor inversion device

8.Foot switch

9.Safety stop and safety plug

10.T-type double handed button operating floor

11.Inspection variable connection magnetic valve

12.Anti-vibration mechanical foot

13.Rapid mold exchanging device

14.Upper die clamper

15.Lower die clamper

16.Die lifter

17.Mould-shift arm

18.Basic bolt and soleplate

19.Automatic feeding device

20.Three-in-one NC straightening feeder

21.NC idler wheel feeder

22.Two-in-one feeder and straightening machine

23.Straightening machine

| Model | APE-160 | APE-200 | APE-250 | APE-300 | APE-400 | APE-500 | APE-600 | Model | A | B |

| Slide Plate Area(LR × FB) | 1600 × 650 | 1850 × 750 | 2100 × 900 | 2200 × 900 | 3100 × 1000 | 3200 × 1000 | 3400 × 1100 | a | 22 | 28 |

| Type of T-Slot | A | 3 | B | 3 | 3 | B | B | b | 37 | 48 |

| Type of T-Slot | 6 | 6 | 6 | 6 | 6 | 6 | 6 | c | 24 | 28 |

| b6 | 375 | 375 | 450 | 450 | 600 | 600 | 600 | d | 16 | 20 |

| b7 | 125 | 125 | 150 | 150 | 200 | 200 | 200 | R | 1 | 1 |

| Specification | APE-160 | APE-200 | APE-250 | APE-300 | APE-400 | APE-500 | APE-600 | |||||||

| Model | S | H | S | H | S | H | S | H | S | H | S | H | S | H |

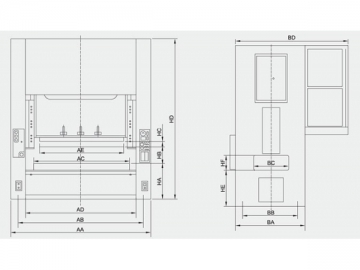

| AA | 2590 | 3000 | 3700 | 3700 | 4100 | 4300 | 4700 | |||||||

| AB | 2240 | 2700 | 3350 | 3350 | 3750 | 3900 | 4250 | |||||||

| AC | 1800 | 2200 | 2500 | 2500 | 3200 | 3300 | 3500 | |||||||

| AD | 1880 | 2290 | 2800 | 2800 | 3300 | 3450 | 3650 | |||||||

| AE | 1600 | 1850 | 2100 | 2100 | 2800 | 2900 | 3100 | |||||||

| BA | 1400 | 1750 | 1800 | 1800 | 2100 | 2300 | 2550 | |||||||

| BB | 1200 | 1550 | 1450 | 1450 | 1940 | 2050 | 2200 | |||||||

| BC | 700 | 900 | 900 | 900 | 900 | 1000 | 1100 | |||||||

| BD | 2150 | 2500 | 2950 | 2950 | 3129 | 3750 | 3900 | |||||||

| HA | 800 | 900 | 1000 | 1000 | 1200 | 1200 | 1200 | |||||||

| HB | 450 | 400 | 500 | 450 | 550 | 450 | 550 | 450 | 550 | 450 | 580 | 480 | 600 | 500 |

| HC | 190 | 130 | 250 | 150 | 280 | 170 | 300 | 170 | 300 | 170 | 300 | 180 | 300 | 180 |

| HD | 3400 | 3300 | 3750 | 3600 | 4250 | 4040 | 4400 | 4170 | 5195 | 4965 | 5870 | 5620 | 6100 | 5870 |

| HF | 900 | 900 | 1000 | 1000 | 1150 | 1150 | 1150 | |||||||

| HE | 450 | 600 | 600 | 600 | 600 | 600 | 600 | |||||||

| Name | Unit | APE-160 | APE-200 | APE-250 | APE-300 | APE-400 | APE-500 | APE-600 | |||||||

| Model | S | H | S | H | S | H | S | H | S | H | S | H | S | H | |

| Capacity | Ton | 160 | 200 | 250 | 300 | 400 | 500 | 600 | |||||||

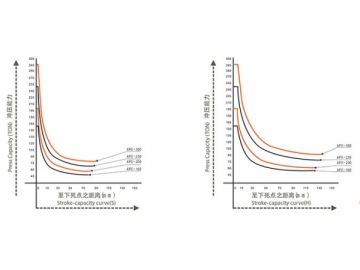

| Rated tonnage point | mm | 6 | 3 | 6 | 3 | 7 | 3 | 7 | 3 | 7 | 3 | 10 | 6 | 10 | 6 |

| Stroke | mm | 180 | 130 | 250 | 150 | 280 | 170 | 300 | 170 | 300 | 170 | 300 | 180 | 300 | 180 |

| Stroke per minute | s.p.m | 30-55 | 40-85 | 20-50 | 35-70 | 20-40 | 30-60 | 20-35 | 30-50 | 20-30 | 20-40 | 18-25 | 20-30 | 15-25 | 20-30 |

| Die height | mm | 450 | 400 | 500 | 450 | 550 | 450 | 550 | 450 | 550 | 450 | 580 | 480 | 600 | 500 |

| Slide adjustment | mm | 100 | 120 | 120 | 120 | 120 | 120 | 120 | |||||||

| Slide area | mm | 1600×650 | 1850 × 750 | 2100×900 | 2100×900 | 2800×1000 | 2900×1000 | 3100×1100 | |||||||

| Bolster area | mm | 1800 × 760 | 2200×940 | 2500×1000 | 2500×1000 | 3200×1000 | 3300×1200 | 3500×1200 | |||||||

| Side opening | mm | 700×450 | 900×600 | 900×600 | 900×600 | 900×600 | 1000×750 | 1100×750 | |||||||

| Main motor | KwxP | 15×4 | 18.5×4 | 22×4 | 30×4 | 37×4 | 45×4 | 55×4 | |||||||

| Slide adjust mechanism | KwxP | 1×4 | 2×4 | 2×4 | 2×4 | 2×4 | 3×4 | 3×4 | |||||||

| Air pressure | kg/cm2 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | |||||||

| Press precision | GB(JIS)1 class | ||||||||||||||

Download PDF