300C Egg Processing Line with Cleaning, Separating (10000 EGGS/HOUR)

ZENYER 300C liquid egg processing line is comprised of the and . Suitable for pre-washing before separating chicken eggs.Made of strong stainless steel for great durability and hygiene and meets all safety and food processing requirements for companies that use egg liquids, such as bakeries, cake factories, dessert factories, and other food processing industries.

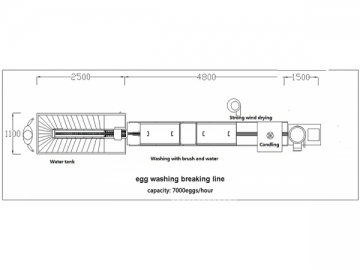

| Product name | Egg washing & crashing line |

| Product code | 300C |

| Model | ZYL-DS1-PS |

| Capacity | 7000-10000 eggs/hour |

| Material | Stainless steel |

| Power | 10.2 KW |

| Voltage | 380V,50HZ, Three-phase |

| Dimension(L×W×H) | 8.2 ×1.7×1.35 M |

| Function | Water bath loading, sanitizer spraying, washing, drying, candling, separating egg shells and liquids |

- Water bath loading

- Washing

- Drying

- Candling(Option)

- Centrifugal mechanism separating

Pour the entire box or tray of eggs into the bath, and the eggs will then be conveyed to the washer entrance.

Eggs are fully cleaned using two sets of brushes with a warm water spray. Brush modules are flexible and adjustable in terms of brush distance, position, and speed.

Eggs are perfectly dried using a strong air pressure.

Eggs will run through LED lights for a candling purpose, allowing users to easily remove any unqualified eggs, such as those that leak or are cracked.

ZENYER is made using a specially designed centrifugal mechanism operation system. Once the eggs are poured into the separator, the centrifugal mechanism will separate the shells and liquids through a high speed spinning process.

After separation is finished, whole egg liquids will flow out from the round tube and eggshells will be pushed out from the square exit.