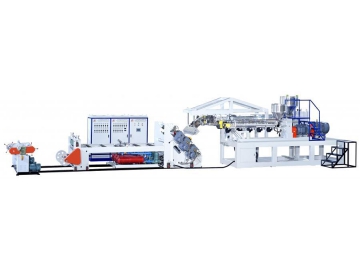

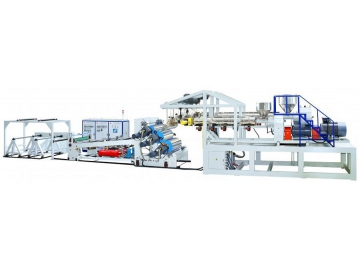

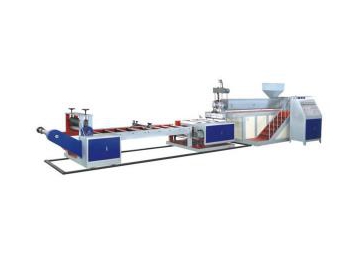

Single Layer Plastic Extruder (PP, PS Sheet Extrusion)

Recommended application

Single layer plastic extruder is mainly applied to manufacture single plastic sheet of PP, PS and other materials. Then these plastic sheet can be processed into plastic container, plastic cup, plastic cover with the help of thermoforming machine, which are widely applied to plastic packaging fields and so on.

- Finished products

- Sheet materials

- Sheet materials

Technical progress

Display screen for controlling

Display screen for controlling Winding device

Winding device

We can provide different manufacturing lines with different specifications and configurations for customers according to their specific manufacturing requirement. There are two model of plastic extruders with technical parameters as follows for your reference.

| Model | Applicative materials | Screw specification | Calender bowl specification | Sheet thickness | Sheet width | Extrusion capacity | Installed capacity |

| mm | mm | mm | mm | kg/h | kW | ||

| SJP120-1000 | PP,PS | Φ120 | Φ330×1000Φ490×1000Φ490×1000 | 0.2-2.0 | ≤850 | 500-700 | 280 |

Feature of single layer plastic extruder

1. The single layer plastic extruder adopts full-automatic feeding device and can largely improve production efficiency.

2. The extrusion outlet is equipped with melt dosing pump and can realize quantitative steady pressure output, which can achieve automatic closed-loop control of pressure and speed.

3. The total machine adopts PLC control system, which can realize automatic control for parameter setting, date operation, feedback, alarming and other functions.

4. The machine is designed with compact structure and has the advantages of small floor area and convenient maintenance.