Multi-Layer Plastic Extruder (PP, PS, HIPS, PE Sheet Extrusion)

Description

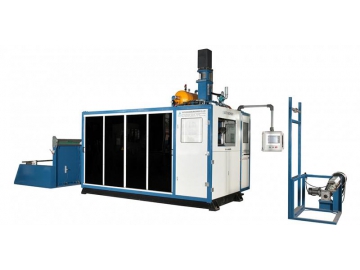

Multi-layer plastic extruder adopts several extruders and is mainly applied to manufacture multi-layer plastic sheet of PP, HIPS, PE and other materials meeting the requirement of different applications. These plastic sheet can be used to make plastic containers, plastic trays, plastic cup, plastic covers with the help of thermoforming machine, which are widely applied to printing, packaging, hardware packaging and so on.

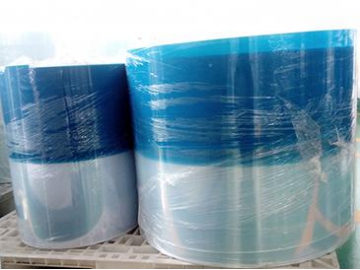

Double-color sheet materials

Double-color sheet materials Double-layer sheet materials

Double-layer sheet materials

Technical progress

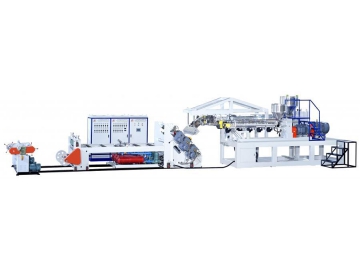

- Shooting on the factory

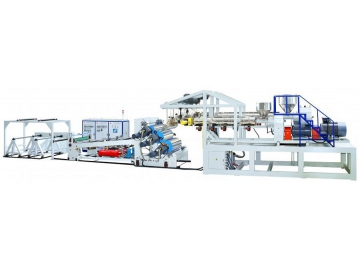

- Shooting on the factory

- Shooting on the factory

We can provide different manufacturing lines with different specifications and configurations for customers according to their specific manufacturing requirement. There are four model of multi-layer plastic extruders with technical parameters as follows for your reference.

(1) WSJP90/50-900 Multi-Layer Plastic Extruder (PP, PS, HIPS, PE Sheet Extrusion)| Layer number | Screw specification | Calender bowl specification | Sheet thickness | Sheet width | Extrusion capacity | Installed capacity |

| mm | mm | mm | mm | kg/h | kW | |

| < 3 | Φ90/Φ50 | Φ318x900Φ420x900Φ420x900 | 0.2-2.0 | ≤780 | 100-250 | 200 |

| Layer number | Screw specification | Calender bowl specification | Sheet thickness | Sheet width | Extrusion capacity | Installed capacity |

| mm | mm | mm | mm | kg/h | kW | |

| < 3 | Φ105/Φ90 | Φ330x1000Φ490x1000Φ490x1000 | 0.2-2.0 | ≤880 | 150-450 | 280 |

| Layer number | Screw specification | Calender bowl specification | Sheet thickness | Sheet width | Extrusion capacity | Installed capacity |

| mm | mm | mm | mm | kg/h | kW | |

| < 3 | Φ120/Φ90 | Φ330x1000Φ490x1000Φ490x1000 | 0.2-2.0 | ≤880 | 200-650 | 340 |

| Layer number | Screw specification | Calender bowl specification | Sheet thickness | Sheet width | Extrusion capacity | Installed capacity |

| mm | mm | mm | mm | kg/h | kW | |

| < 5 | Φ105/Φ90/Φ65 | Φ330x1000Φ490x1000Φ490x1000 | 0.2-2.0 | ≤880 | 200-500 | 380 |

Feature of multi-layer plastic extruder

1. The single screw plastic extruder in the manufacturing line adopts new type of screw structure featured as stable feeding and uniform fusion mixing, which can reduce energy consumption and increase production output.

2. The plastic extruder adopts directly connection between motor and reduction gears, which can improve transmission efficiency and reduce speed fluctuation ensuring the stability of extrusion.

3. The extruder is designed with the melt dosing pump and it can be cooperated with precise multi-layer distributor. The flow proportion and blade clearance ratio are all adjustable, which can lead to more uniform plastic sheet layer.

4. The total machine adopts PLC control system, which can realize automatic control for parameter setting, date operation, feedback, alarming and other functions.