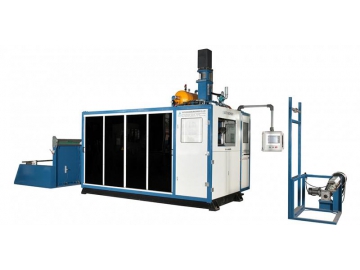

Plastic Sheet Thermoforming Machine

Description

Plastic sheet thermoforming machine is a conventional plastic packaging manufacturing equipment and can be used for heating, extruding and forming of plastic sheet suitable for PP, PS, PET, PVC, PLA and so on, which is mainly applied to manufacture plastic bowl, fast food containers and other disposable food supplies or other plastic packaging products.

| Main motor power | Plug assist servo motor power | Sheet thickness | Forming depth | Work efficiency | Max forming area | Air consumption | Heating power | Machine dimensions | Total weight |

| kW | kW | mm | mm | pcs/min | mm | L/min | kW | m(L*W*H) | T |

| 15 | 11 | 0.3-2.0 | ≤170 | ≤36 | 680×390 | 4000-5000 | 101 | 11×2.3×3.3 | 8 |

Features of Plastic Sheet Thermoforming Machine

1. The plastic sheet thermoforming machine adopts cam transmission, which is featured as stable operation, low noise and convenient maintenance.

2. The forming working platform is supported by four guide pillars. The machine has high precision, low vibration and stable working at the process of forming.

3. The chain track can retreat freely and is very convenient for replacing mould.

4. The feeding of plastic sheet can be finished by servo motor with high feeding precision.

5. The sensitive servo motor is responsible for stretching plastic sheet with stretching velocity, accurate location and convenient operation.

6. The thermoforming machine is equipped with German Elstein infrared ceramic heater, which is featured as quick response, high thermal efficiency, high temperature control accuracy, long service life and low energy consumption.