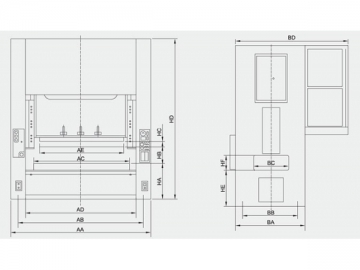

Straight Side Double Crank Press (400-1200 Tons), STD Series

Stamping Machine with High Pressing Forces | Large Sheet Metal Forming | 400 - 1200 Metric Tons Capacity

The STD series straight side double crank press features a wide working surface that is used for large metal forming applications. The punch machine has an enormous pressing capacity range of 400-1200 tons, making it suitable for stamping metal sheets with large thicknesses. The power press is often used in the production of motorcycle parts, bicycle components and household appliances.

1. An octahedral guide for the slider and long guide rail guarantees operational precision.

2. The stamping press for automotive parts features a hydraulic overload protection device and overload automatic emergency cut-off.

3. PLC electric interlocking control allows for sudden stop, inching, single-passing and continuousmetal fabrication.

4. The dry pneumatic friction clutch is quiet, features large clutching torque, a small braking angle and is convenient to maintain.

5. Closed body structure, including beams, stand columns, and bases, which is connected with four tie bolts, with high rigidity (400-600)

1.VS variable-speed motor

2.Oil pressure overload protection device

3.Electric slide adjust device

4.Independent electrical control cabinet

5.Movable working table

6.Die height indicator (unit: 0.1 mm)

7.Electric lubricating device

8.Power socket

9.Over-run safety device

10.Misfeed detection device

11.Preset counter (6 digits)

12.Air jetting device 1/2" primary circuit

13.Air source connector 1/2" secondary circuit

1.Die cushion device

2.Photo-electric safety device

3.Upper slide feeding device

4.Safety stop and safety plug

5.Anti-vibration device

6.Die light

7.Quick die change device

8.Trolley

9.Frequency converter

10.Automatic feeding system

| Name | Unit | STD -400 | STD-500 | STD-600 | STD-800 | STD-1000 | STD-1200 | ||||||

| Model | S | H | S | H | S | H | S | H | S | H | S | H | |

| Capacity | Ton | 400 | 500 | 600 | 800 | 1000 | 1200 | ||||||

| Rated tonnage point | mm | 13 | 7 | 13 | 7 | 13 | 9 | 13 | 9 | 13 | 9 | 13 | 9 |

| Stroke | mm | 400 | 300 | 400 | 300 | 400 | 300 | 400 | 300 | 400 | 300 | 400 | 300 |

| Stroke per minute | s.p.m | 15-30 | 30-60 | 15-30 | 30-60 | 15-30 | 25-50 | 15-30 | 25-50 | 15-25 | 25-40 | 15-25 | 25-40 |

| Die height | mm | 600 | 650 | 650 | 700 | 650 | 700 | 700 | 750 | 1000 | 1050 | 1000 | 1050 |

| Slide adjustment | mm | 150 | 200 | 200 | 250 | 250 | 250 | ||||||

| Slide area | mm | 2800×1300 | 3100×1400 | 3600×1400 | 3800×1600 | 4600×1800 | 5000×1800 | ||||||

| Bolster area | mm | 2800×1400 | 3100×1500 | 3600×1500 | 3800×1600 | 4600×1800 | 5000×1800 | ||||||

| Side opening | mm | 850×600 | 950×650 | 1000×700 | 1100×800 | 1200×900 | 1200×900 | ||||||

| Die cushion capacity | Ton | 60 | 70 | 80 | 80 | 80 | 80 | ||||||

Download PDF