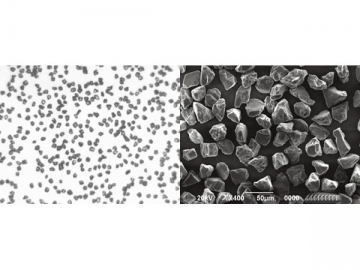

Diamond Micro Powder

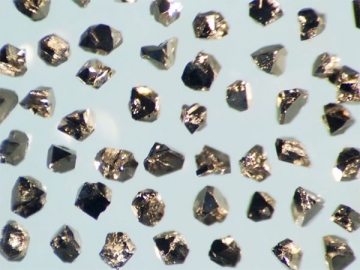

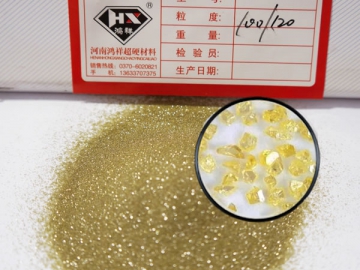

The diamond micro powder is made of select large single-crystal diamond particles through a series of processes, including crushing, re-crushing, sieving, washing, automatic separation, purification, drying and inspection. The resultant diamond powder is either yellow or green, and is shaped with a consistent grain composition and high purity.

Process Flow Diagram

1. Crushing: large diamond particles are crushed into smaller sizes and irregular shapes.

2. Re-crushing: irregular abrasive grits are re-crushed for shape improvement.

3. Sieving: diamond grits are sized through a sieving process and separated into different groups.

4. Washing: the diamond particles are washed.

5. Automatic separation: Impurities are removed from the diamond particles.

6. Drying: diamond powder is then dried.

7. Laser particle size analyzer: the diamond particles are measured.

Diamond Micro Powder Uses

The diamond micro powder is primarily used to produce grinding products, including resin bond, diamond polishing pads, diamond polishing disks, diamond compounds, and diamond wire dies,lapping paste, PDC, PCD and more. Diamond micron powder is also designed for grinding, lapping, polishing, and fine finishing applications. It is a highly efficient abrasive for machining ceramic, precious stones, hard alloy, electronic products and optical instruments.

| Synthetic Diamond Micro Powder | |||

| Chinese Standards | International Standards | Mesh Size | D50um |

| W0.25 | 0-0.25 | 60000 | 0.11 ~ 0.20 |

| W0.5 | 0-0.5 | 30000 | 0.20 ~ 0.30 |

| W1 | 0-1 | 15000 | 0.6 ~ 0.8 |

| W1.5- | 0-2 | 13000 | 1.1 ~ 1.2 |

| W1.5 | 1-2 | 12000 | 1.1 ~ 1.3 |

| W2.5 | 1-3 | 10000 | 1.6 ~ 1.8 |

| W3 | 1-4 | 7000 | 1.9 ~ 2.1 |

| W3.5 | 1-5 | 6500 | 2.2 ~ 2.6 |

| W3.5 | 2-4 | 6000 | 2.6 ~ 3.0 |

| W4 | 2-5 | 5000 | 3.1 ~ 3.4 |

| W5 | 2-6 | 4000 | 3.5 ~ 4.2 |

| W6 | 3-7 | 3500 | 4.4 ~ 5.0 |

| W7 | 4-8 | 3000 | 5.0 ~ 6.0 |

| W10 | 4-9 | 2500 | 6.1 ~ 6.5 |

| W10 | 5-10 | 2000 | 6.5 ~ 7.3 |

| W10 | 6-11 | 1800 | 7.3 ~ 8.3 |

| W12 | 8-12 | 1600 | 8.3 ~ 9.0 |

| W14 | 7-14 | 1500 | 9.1 ~ 10.5 |

| W14 | 8-15 | 1300 | 10.0 ~ 12.0 |

| W20- | 10-20 | 1200 | 12.5 ~ 15.0 |

| W20 | 12-22 | 1000 | 15.0 ~ 17.0 |

| W20 | 15-25 | 800 | 18.0 ~ 20.0 |

| W28 | 20-30 | 700 | 20 ~ 23 |

| W28 | 22-36 | 600 | 23 ~ 26 |

| W40- | 20-40 | 500 | 26 ~ 29 |

| W40 | 30-40 | 450 | 29 ~ 32 |

| W40 | 35-45 | 400 | 32 ~ 36 |

| W50 | 36-54 | 37 ~ 43 | |