Micro Twin Extruder

We developed and manufactured the bimetallic barrel and bimetallic screw with more wear-resistant and corrosion-resistant alloy protective layers, enabling our products to feature extremely high wear and corrosion resistance. Not only do we provide all kinds of high-output and high-speed single screw extruder, we also offer the normal parallel ,, which are commonly used for compounding modification. In recent years, we have adopted our core material technology to research and develop ceramic membrane extruders which are used for manufacturing the materials featuring high resistance to friction, wear and alkaline corrosion, and the exterior wall insulation and decorative boards. Various micro twin (micro-conical) extruders were specially developed for pharmaceutical compounding and core materials.

In the early formulation development of new drugs, scientists often need to configure a micro-twin (micro-conical) compounding extruder that can be used for pharmaceutical materials with size as small as nanometers. We conducted deep research into this field as user’s request to develop the micro-twin (micro-conical) extruder. We are well aware that this development is expected to be difficult due to the special "mini" characteristic of the extruder. Featuring advanced extrusion technology and long service life, the micro-twin extruder developed can adapt to extremely harsh working conditions, which fills the gap in the extrusion industry in China.

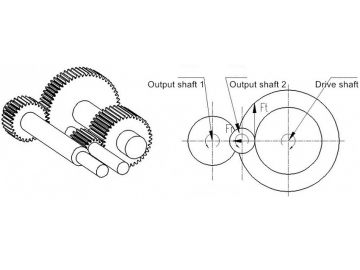

We encountered many unimaginable challenges in the development of the above extruders. For example, the power system needs to be designed with the dual-shaft output due to the limited space of the micro-extruder. We have no experience for reference and no ready-made products existed in China. In addition, as we all know when the mechanical parts are extremely small, which is extremely difficult to machine. Micro-twin (micro-conical) barrels and screws normally have extremely high precision requirements and strict quality requirements. Many micro-twin (micro-conical) screws even need to be manufactured on a four-axis linkage machining center to meet the standards. This is the reason why many domestic professional companies were discouraged and refused to work with us, when they saw our barrel and screw design drawings.

The picture on the right shows a micro-twin segmented screw and its barrel, miniature conical barrel and screw, various types of single-screw manufactured by our company. Our company has adopted special manufacturing materials in history, and has accumulated a lot of valuable experience in the production of core components of micro-twin (micro-conical) extruders. We are willing to share these precious production experience and results with your professional company.

Welcome to discuss and let us make progress together in the field of "Mini" extruders.