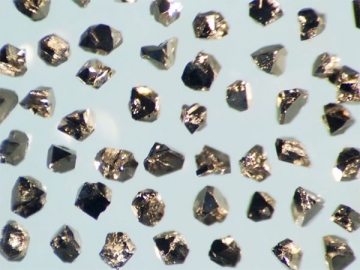

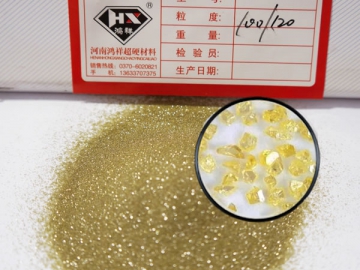

Synthetic Diamond Powder (MBD and SMD)

Both MBD and SMD range synthetic diamond powders are super-hard abrasive materials, with cubo-octahedron crystals delivering a high impact strength, unsurpassed thermal strength and stability.

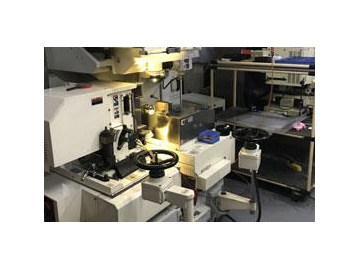

Process Flow Diagram

1. Hydraulic press: The press is where diamond crystal are grown under high temperature and pressure conditions.

2. Sieving machine: different sized crystals are achieved using a sieving process.

3. Washing machine: Impurities are removed from the diamond.

4. Drying machine: the wet diamond crystals are dried.

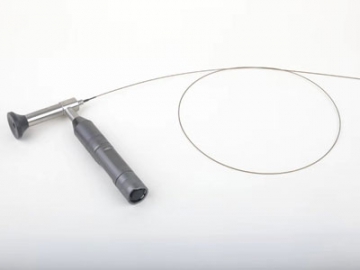

Beyond the general imprint as a functional part of cutting tools for working hard stones and concrete, these synthetic diamond powders are also becoming more common in electroplating tools and drills for construction, mining and oil industries.

These super hard synthetic diamond powders are an excellent choice for grinding glass, ceramic, hard alloy, stones, concrete and refractories.

| Grain Size | Chinese Standards | FEPA | Mesh Size |

| (micron) | GB/T6406-1995 | ||

| Grain Code | Grain Code | ||

| 600/425 | 30/40 | D602 | 40# |

| 425/355 | 40/45 | D426 | 45# |

| 355/300 | 45/50 | D356 | 50# |

| 300/250 | 50/60 | D301 | 60# |

| 250/212 | 60/70 | D251 | 70# |

| 212/180 | 70/80 | D213 | 80# |

| 180/150 | 80/100 | D180 | 100# |

| 150/125 | 100/120 | D151 | 120# |

| 125/106 | 120/140 | D126 | 140# |

| 106/90 | 140/170 | D107 | 170# |

| 90/75 | 170/200 | D91 | 200# |

| 75/63 | 200/230 | D76 | 230# |

| 63/53 | 230/270 | D64 | 270# |

| 53/45 | 270/325 | D54 | 325# |

| 45/38 | 325/400 | D46 | 400# |