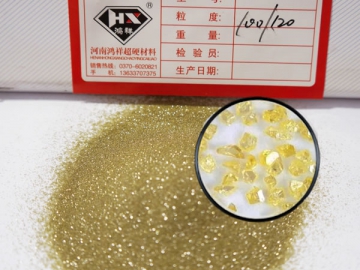

Coated Synthetic Diamond Powder

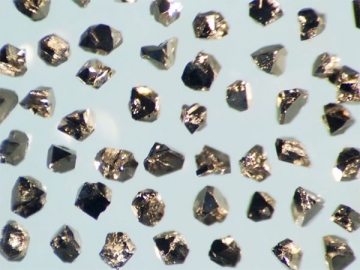

Coated synthetic diamond powder is less likely to be oxidized than a non-coated one, and delivers a higher strength and easier bonding with metal or resin.

There are a number of benefits to using diamond abrasives in making tool bits. Diamond particles won't chip off of the tool, making it sharper and more wear resistant. Coated synthetic diamond powder is primarily designed for cutting, grinding, trimming and polishing applications.

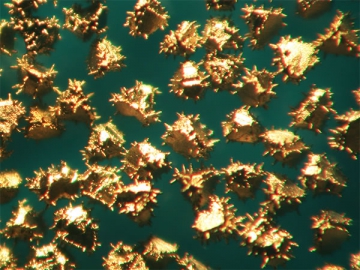

Electroplating and electroless plating are used to add coating to synthetic diamonds. Metals typically used as the coating include nickel, titanium and copper, and generally add 30% or 56% more weight to the diamond powder.

Both titanium and nickel coated diamond are commonly used to produce metal and ceramic bonded diamond tools. The titanium coating also enhances the physical bond of the diamond particles to the bond matrix. The coating also extends the service life of the diamond tool.

Coated Diamond Uses

Resin bond wheels, metal bond wheels

| Grain Size | Chinese Standards | FEPA | Mesh Size |

| (micron) | |||

| Grain Code | Grain Code | ||

| 600/425 | 30/40 | D602 | 40# |

| 425/355 | 40/45 | D426 | 45# |

| 355/300 | 45/50 | D356 | 50# |

| 300/250 | 50/60 | D301 | 60# |

| 250/212 | 60/70 | D251 | 70# |

| 212/180 | 70/80 | D213 | 80# |

| 180/150 | 80/100 | D180 | 100# |

| 150/125 | 100/120 | D151 | 120# |

| 125/106 | 120/140 | D126 | 140# |

| 106/90 | 140/170 | D107 | 170# |

| 90/75 | 170/200 | D91 | 200# |

| 75/63 | 200/230 | D76 | 230# |

| 63/53 | 230/270 | D64 | 270# |

| 53/45 | 270/325 | D54 | 325# |

| 45/38 | 325/400 | D46 | 400# |