Turntable Shot Blasting Machine

The turntable shot blasting machine uses blast wheels to spray high-speed abrasives onto the surface of work pieces on the turntable to remove sand, mill scale and other contaminants, so work pieces will obtain gloss surface with a certain level of roughness.

Application

Our shot blast machine is utilized for the surface cleaning of small to medium sized castings, forgings, weldments as well as metal parts that are flat, thin-walled or sensitive to shock, and it is particularly suitable for the surface peening of gears, shafts, springs, pull rods and heat treated components. So, this abrasive blast equipment has been extensively used in casting and automobile industries.

System Configuration

Our turntable shot blasting machine is characterized by compact structure, remarkable sealing effect, high production efficiency and easy loading/unloading since it is a high-tech product composed of reliable components.

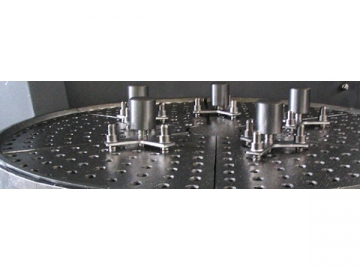

1. Blast Chamber

Welded by steel plates and steel profiles, the blast chamber possesses excellent mechanical strength, and it is lined with 10-mm-thick ZCr5 plates at major blasting zones, while other positions are internally protected by wear resistant rubber plates. All the lining plates are fixed by special nuts to simplify replacement, and the two leaf door also uses wear resistant rubber plates as its lining materials.

The blast wheel assembly is an integration of blast wheel, turbine, V-belt and bed plate, and its position and angle are determined by 3D dynamic simulation so as to offer complete coverage. For better product quality, the blade, impeller and control cage are all made via precise investment casting.

3. Abrasive Reclamation System

The turntable shot blasting machine’s abrasive reclamation system contains bucket elevator, sand separator, abrasive silo, pneumatic valve, abrasive delivery chute, etc.

It is formed by turntable, drive mechanism and other auxiliary devices.

5. Dust Removal SystemOur turntable shot blasting machine takes advantage of a three stage dust removal system to remove dust. More specifically, large particles are separated first by settling box and cyclone dust extractor, and finally a cartridge filter is used to remove over 99.5% of micron sized dust.

6. Electrical Control SystemThis metal surface cleaning equipment adopts conventional electrical control, and its electrical devices are famous brands in China. Thanks to the inter-locking function, stable performance is delivered in a safe way.

Ordering Information

Different customers may have different needs when it comes to shot blasting, so we are willing to customize turntable shot blasting machine in max. work piece size, number of blast wheel, number of work station, size of blast chamber and other aspects to better meet customer requirement.

| Item | Unit | | | |

| Turntable diameter | mm | Ф1200 | Ф1800 | Ф2500 |

| Max. load capacity | kg | 500 | 800 | 1000 |

| Max. work piece size | mm | ≤1200 | ≤800 | ≤2500 |