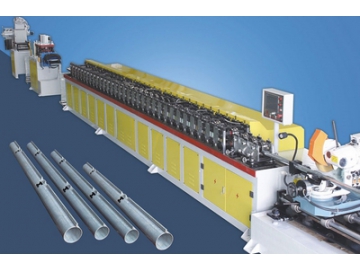

Shot Blasting Machine for Pipes

The shot blasting machine for pipes offers remarkable cleaning result for steel pipes to restore their natural metallic luster, and it is further classified into two series which are QGW and QGN. The QGW external pipe blasting machine is intended to clean the external surface of steel pipe whose diameter is within 16-2800mm, while the QGN internal pipe blasting machine could clean the internal surface of steel pipes with diameter range of 50-1500mm.

Application

Our pipe shot blasting machine fits for blast cleaning of steel pipes that are used to deliver tap water, natural gas, coal gas, petroleum and other media since it significantly improves surface condition of steel pipes.

Ordering Information

The shot blasting machine for pipes is available in bespoke configurations to better satisfy every customer, and the customizable list covers max. work piece size, number of blast wheel, number of work station, size of blast cabinet, etc.

Our QGW external pipe shot blasting machine is an integration of the following parts.

1. Blast CabinetThe blast cabinet is constructed by welding Q235 steel plate and profile steel together, and it is a fully enclosed operation room with an inspection door. Moreover, it is lined with 10-mm-thick high chromium steel plates, and these plates are connected and fixed by protective nuts to simplify replacement.

2. Blast Wheel AssemblyBlast wheel is the core part of blast wheel assembly, and we use DP180 blast wheel that is fabricated using PANGBORN technology. It is a highly efficient blast wheel with one disc and several curved blades, and it offers thorough cleaning with minimized dead zone.

3. Abrasive Reclamation System

The abrasive reclamation system contains bucket elevator, sand separator, pneumatic valve, abrasive delivery chute and other components.

Thanks to the implementation of reverse pulse jet cartridge dust collector, the dust removal system is able to provide excellent performance for a long time.

5. Electrical Control System

This shot blasting machine is controlled by a Siemens PLC controller, and its frequency converter is also made by Siemens while other electrical devices are genuine CHINT products. The electrical control system allows easy changeover between manual mode and automatic mode via a specialized switch, and its inter-locking, self-locking and failure warning functions help to ensure safe running.

| Model | Pipe size (mm) | Cleaning speed (m/min) | Purpose |

| | Ф50-300 | 2-10 | Shot blasting external surface of steel pipes |

| | Ф159-720 | 2-6 | |

| | Ф219-1016 | 1-6 | |

| | Ф325-1600 | 1-6 | |

| | Ф1016-2800 | 1-2 |

The QGN internal pipe shot blasting machine consists of blast wheel assembly, pre-blastroom, post-blastroom, abrasive reclamation system, abrasive separation system, work piece rotation system, dust removal system, hydraulic control system, pneumatic control system, electrical control system, etc. Here are introductions to some major parts.

1. Movable Pre-Blastroom and Post-Blastroom

These auxiliary rooms allow fore and aft movement to encapsulate both ends of steel pipes to be treated by our shot blasting machine, and they are produced by welding steel plates and steel profiles together so as to provide sufficient mechanical strength. In addition, lightweight but rigid brush seals are adopted to avoid abrasives splashing out of the chamber.

For this shot blasting machine, its blast wheel assembly uses a double disc blast wheel with linear blades, and these components are arranged in a compact way to facilitate maintenance. All the blades have received strict trimming and polishing after they are cast, and they are matched according their weight as indicated by a scale, thus ensuring excellent dynamic balance (unbalanced moment is less than 15N·mm) which is beneficial for noise reduction.

3. Abrasive Reclamation System

The abrasive reclamation system contains screw conveyor, bucket elevator, sand separator, abrasive silo, pneumatic valve and other components.

4. Pipe Transport TrolleyThe pipe transport trolley is mainly used to side shift pipes, rotate pipes and lift pipes (to remove abrasives), and it delivers pipes to loading/unloading device to realize automatic work flow, thus saving labor and offering better control over pipes.

5. Loading and Unloading Device

Owing to the loading and unloading device, operators are not only released from heavy work, but are also well protected from potential danger.

Our shot blasting machine makes use of HR series cartridge filters to remove dust efficiently. This dust collector is manufactured on the basis of leading-edge foreign technology, and it is featured by convenient use, little maintenance, excellent regenerability, life service life, high utility rate of space, good energy saving property, etc.

7. Electrical Control SystemThis internal pipe shot blasting machine is completely controlled by an electrical control system. This system consists of a Siemens PLC controller and other high-quality electrical devices, and it boasts high degree of automation, multiple protection functions and reliable performance.

Technical Data of QGN Shot Blasting Machine for Pipes| Model | Pipe size (mm) | Cleaning speed (m/min) | Purpose |

| | Ф50-300 | 1-4 | Shot blasting internal surface of steel pipes |

| | Ф325-720 | 1-2 | |

| | Ф720-1016 | 1-4 | |

| | Ф1016-1500 | 1-4 |