Shot Blasting Machine for Coil Springs

The shot blasting machine for coil springs makes use of highly efficient and energy saving blast wheels to propel high-velocity abrasive streams onto the surface of coil springs, and each abrasive functions like ball-peen hammer to create compressive residual stress in the surface. As a result, the mechanical properties of coil springs are modified, thus enhancing their resistance to fatigue and corrosion. In addition, this shot peening machine could be customized to best fit very practical application.

System Configuration

Our shot blasting machine is mainly composed of blast chamber, pre-blastroom, post-blastroom, blast wheel assembly, abrasive reclamation system, work piece transport system, work piece rotation system, dust removal system, electrical control system and pneumatic control system.

Made from Q235 steel plates and steel profiles via welding, the blast chamber boasts superior strength and stiffness, and it has 6 access doors which are lined by high chromium steel plates and sealed by foamed rubber seal strips on four sides. The chamber is also protected by high chromium steel plates, and these plates are fixed by protective nuts to facilitate replacement.

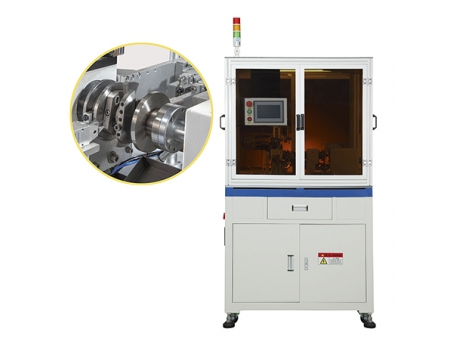

2. Blast Wheel AssemblyFor our shot blasting machine for coil springs, its blast wheel assembly is mainly made up of blast wheel, turbine, V-belt and belt pulley, while the position and angle of blast wheel assembly are determined by computer-aided 3D dynamic simulation to realize complete coverage. Moreover, the applied 180-4RK blast wheel is fabricated using PANGBORN technology, and it has single disc and curved blades.

3. Abrasive Reclamation SystemThe abrasive reclamation system consists of screw conveyor, bucket elevator, sand separator, pneumatic valve, abrasive delivery chute and so on.

4. Dust Removal SystemThis coil spring shot peening machine incorporates dust collector, blower, settling box and pipeline together to form an effective dust removal system.

5. Electrical Control SystemControlled by a Siemens or Omron PLC controller, this shot blasting machine is fitted with a specialized switch to allow operators to change working mode between manual and automatic conveniently, and its frequency converter is provided by Siemens. Thanks to the inter-locking, self-locking and other safety functions, our coil spring shot blasting machine is able to work safely all the time.

Technical Data of Shot Blasting Machine for Coil Springs| Item | Unit | | | |

| Max. work piece size | mm | Gear: Ф1500×1700 Inner wheel: Ф400×2000 Height: 200-500 | Gear: Ф3000×1500 Inner wheel: Ф400×2500 Height: 200-500 | Diameter: 50-300 Length: ≤700 |

| Rotary table size | mm | Ф1500 | Ф3000 | - |

| Movable table size | mm | Ф500 | Ф1000 | - |

| Load capacity of rotary table | kg | 5000 | 15000 | - |

| Power of blast wheels | kW | 3×18.5 | 3×18.5 | 30 |

| Power of movable blast wheel | kW | 1×18.5 | 1×18.5 | - |

| Abrasive consumption | kg/min | 4×280 | 4×280 | 420 |

| Model of dust collector | - | HR4-16 | HR4-32 | JZC40 |

| Air requirement | m3/h | 1000 | 22000 | 5940 |

| Total power (without dust removal system) | kW | 107.15 | 119.3 | 40.05 |

| Machine size | mm | 9350×3750×8790 | 12000×5250×8750 | 8230×762×1752 |