Spinner Hanger Shot Blasting Machine

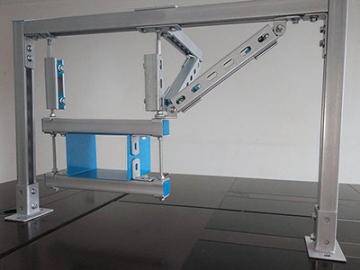

The spinner hanger shot blasting machine offers a reliable blast cleaning solution for different kinds of work pieces, and it is typically designed to handle medium and large components that cannot be tumbled in bulk loads. In addition, with a compact structure, high productivity and no foundation pit, this surface treatment equipment has been extensively utilized in various industries.

System Configuration

Our spinner hanger shot blasting machine is mainly composed of the following parts.

The blast cabinet body is formed by welding Q235 steel plate and profile steel together, and there are 2/3/4 QY360 blast wheels on one side of its wall to provide thorough cleaning for work pieces to be shot blasted.

The blast cabinet is lined with 10-mm-thick ZCr5 steel panels, and these panels are connected together (overlap joint) by protective nuts to facilitate replacement when necessary. At the bottom side, steel plates are inclined to form a funnel so as to let shots flow into the screw conveyor underneath.

As for the door, it has two leaves and is pneumatically controlled. Its inner wall is lined with 6-mm-thick 65Mn steel plates which are fixed by special protective nuts, and foam rubber seals are also adopted to well seal the door. Moreover, our spinner hanger shot blasting machine sets a baffle plate between door leaves to prevent shots from flying out of the cabinet, and there is an abrasive collection slot under the door to collect abrasives that are taken out when opening the door.

2. Blast Wheel AssemblyThe blast wheel assembly is very important for a hook type blast machine, and it contains blast wheel, turbine, belt pulley, V-belt, bed plate and other components. In particular, the QY360 blast wheel is manufactured using Japanese technology, and it boasts high efficiency, stable performance and long service life.

3. Screw ConveyorThe screw shaft is machined as a whole after it is welded, and this method ensures its good concentricity. What is more, its screw blades are fabricated from 16Mn steel via special treatment to make the pitch and outer helix dimensions exceptionally precise, while its bearing is sealed with labyrinth seal, PU seal ring and base plate to better protect the bearing from being damaged by abrasive stream. In this way, both the bearing and screw blades are well protected, and long service life is expectable.

Our spinner hanger shot blasting machine sets a pulse wheel at one end of the shaft to detect working status of the conveyor. So, if the screw conveyor breaks down, signals will be sent to the PLC controller in time.

4.Bucket Elevator

This spinner hanger shot blasting machine’s bucket elevator is made up of cycloidal speed reducer, conveying rubber belt, belt pulley, HT150 hopper, housing and tensioning device.

To avoid belt skidding and abrasive trapping, a squirrel cage pulley is adopted since it not only increases friction between rubber belt and belt pulley, but also cuts down pre-tensioning force of the rubber belt, thereby prolonging the service life of rubber belt.

The cycloidal speed reducer has a braking function, and this helps to avoid reverse running of rubber belt and hopper even when power fails.

5. Separator

The separator is mainly composed of winnowing zone, rotary screen and other parts.

6. Abrasive Silo and Gate

Our spinner hanger shot blasting machine sets an abrasive delivery chute under the abrasive silo in order to transport abrasives from silo to blast wheel, whilst the abrasive gate, which is installed on delivery chute, is controlled by an air cylinder, and this control method solves some annoying problems that are often generated when electromagnetic control is used, such as malfunction, untight gate closing, etc.

A reliable hoisting system is essential for this abrasive blast equipment because it is responsible for lifting and rotating work pieces, and its major components include electric chain hoist, chain wheel, special hook, guide rail, etc.

8. Dust Removal SystemComposed of dust collector, blower, settling box and pipelines, the dust removal system takes advantage of two stage dedusting process to remove dust completely: large particles are separated inside the settling box, and then a cartridge filter is used for further dust removal.

9. Control SystemThe spinner hanger shot blasting machine is controlled by a conventional electrical control system, and interlocking function is provided to avoid misoperation.

Technical Data of Spinner Hanger Shot Blasting Machine| Item | Unit | | | | | | | |

| Max. work piece diameter | mm | Ф600 | Ф800 | Ф800 | Ф1400 | Ф1600 | Ф1800 | Ф2000 |

| Max. work piece height | mm | 1100 | 1500 | 1850 | 2300 | 2200 | 2500 | 3000 |

| Loading capacity (single hook) | kg | 600 | 800 | 1000 | 2000 | 3000 | 5000 | 8000 |

| Abrasive consumption rate | kg/min | 2×120 | 2×160 | 2×250 | 3×250 | 3×250 | 4×250 | 4×250 |

| Cleaning time for one hook | min | 16 | 14 | 14 | 14 | 14 | - | - |

| Productivity of elevator | t/h | 15 | 20 | 30 | 45 | 45 | 60 | 60 |

| Productivity of separator | t/h | 15 | 20 | 30 | 45 | 45 | 60 | 60 |

| Air requirement | m3/h | 2800 | 8300 | 9000 | 15000 | 15000 | 18000 | 18000 |

| Power (without dust removal system) | kW | 22 | 30 | 36.55 | 61.27 | 64.4 | 78.4 | 81.5 |