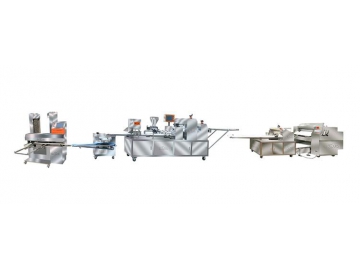

Bread and Hamburger Bun Making Machine

Our bread and hamburger bun making machine is utilized by food producers for baking various French rolls, baguettes, hand tearing breads, sandwich hamburger bun bread, etc. The bread and hamburger bun making machine is made up of a three roll dough sheeter, stuffing filling machine, dough shaping machine and baking tray arranging machine.

Processing line details displayPlace the rolled dough on the conveying belt.

Put the dough wrapper on the conveying belt to enter the dough roll.

Through three roll dough sheeter, the thickness can be adjusted to your needs.

Dough cutting rollers gives you the product shape that you want.

By adding stuffing filling machine, breads with stuffing can be made via filling stuffing and rolling into dough column.

The dough sheet is rolled into circular column by dough roll and then enters next process.

The rolled circular column is shaped and formed by forming machine.

Dough wrapper is rolled and expanded through three roll dough sheeter and rolling device. The three roll dough sheeter makes the dough wrapper glossier and more stable in quality. Each dough roll has a thickness adjusting device for setting the dough thickness. This allows for the product weight to be adjusted.

With multiple feeding methods for filling stuffing, it can stuff many different fillings with great efficiency.

This device is used for bread and hamburger bun forming. The cutter can be replaced and the mold and accessories can be freely matched according to product demands. This machine can produce dough weighing 20-150g.

The finished product needs no manual baking tray arranging. The produced pie and pastry can be placed in the baking tray in parallel or cross arrangement methods. Different machine models can be customized based on different specifications of baking trays.

| Overall size (L x W x H) | 5800x720x1560mm |

| Output | 1000-12000 pcs/h |

| Equipment power | 4.5kw |

| Equipment weight | 980kg |

| Equipment voltage | 220/380V |

| Finished product weight | 15-180g/pc (bread or bun) |

| Equipment frequency | 50HZ/60HZ |

- The main machine parts adopt food grade 304 stainless steel, satisfying the food production requirements.

- Electric elements adopt 750w Taiwan Ott gear motor, Japanese Mikipulley clutch 025, Delta PLC and other famous brands. So its performance is stable and reliable.

- This making equipment equips with PLC touch screen and servo motor control, having functions of synchronous speed regulation. This facilitates operation and programming.

- After being rolled and extended by three roll dough sheeter and dough rolling device, the dough wrapper is glossier and more stable in quality.

- The added dough cutting rollers can operate strip and mesh patterns on the dough wrappers to make the finished products more diversified.

- The accessories are purchased from SAMPLA conveyor, Kunlun Tongtai touch screen and SIKE photo electricity, making each process of the processing line run orderly.

- The weight and size of the dough column can be adjusted.