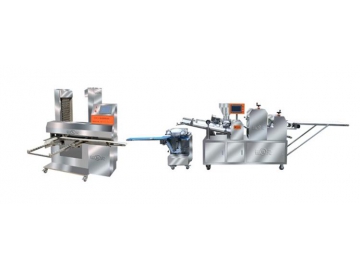

Steamed Bun Machine (Stuffed Buns Line)

The steamed bun machine can produce vegetable buns, tofu buns, sugar buns, meat buns and many other types of stuffed buns with great efficiency. This solves the problem of single stuffing filling of other steamed bun machines in the market. It is widely used in schools, frozen food factories and other fields. It consists of a three roll dough sheeter, Stuffing Filling Machine, dough forming machine and tray arranging machine.

Processing line details displayPut the kneaded dough on the conveyor belt

Enters the dough sheeter, and the dough sheet thickness is adjustable by adjusting the handle.

Fill stuffing via the stuffing filling machine, include vegetable stuffing and meat stuffing.

Then it is rolled into circular column by dough roller.

Use the forming machine to shape patterns.

Tray arranging for dough proofing.

It matches with Stuffing Filling Machine and forming machine to produce steamed bun and other pastas. Adopting handwork-imitating and pressing technology, it does not damage the gluten.

It fills stuffing evenly, applicable to the stuffing filling of steamed buns, pastries, breads and other foods. The stuffing filling head can be changed easily.

This machine is used together with other machines to complete the final shaping process in bread, pastry, steamed bun, pie, round steamed bun, etc. The sheet thickness and stuffing amount are adjustable. This completely solves the current common phenomenon of thin dough wrapper or broken wrapper on the bun bottom.

This machine is utility model of food machinery in various pastas manufacturer. Its use can increase the product output and greatly saves labor. Thus the production cost is reduced, bringing good economic benefits to enterprises. It is suitable for large, medium and small bread and filling cake producers.

| Overall size (L x W x H) | 4900x800x1500mm |

| Output | 1000-6000 pcs/h |

| Equipment power | 4.8kw |

| Equipment weight | 720kg |

| Equipment voltage | 220/380V |

| Finished product weight | 30-150g/pc (special size can be customized) |

| Equipment frequency | 50HZ/60HZ |

| Ratio of wrapper and stuffing | adjustable |

- The thickness of the steamed bun can be adjusted through operation system, which is convenient.

- The produced products have neat patterns, which are more beautiful than the handmade products.

- Each food machine can be freely combined to achieve product diversification, producing various steamed buns, stuffed buns and other stuffing filling products.

- The main parts are all made of stainless steel, satisfying food hygiene standard.

- The forming, stuffing filling, dough feeding and control panel are all driven by independent motors. It is not easy to occur associated failures and is convenient for maintenance, disassembly and cleaning.

- This steamed bun making line adopts high quality micro-computer control. The control panel of easy operation makes the control accurate and reliable. It is fast to master the operation only in 5 minutes.

- With PLC control system, high automation and accurate quantification, the products have uniform size. The dough sheet is adjustable in thickness, forming and cutting size. And this machine can be operated by one or two person.