Single Point Gap Frame Press

DG1 Stamping Presses

- Capacity 25T to 315T

- Strokes per minute 30SPM to 200SPM

- Stroke length 30mm to 250mm

- Slide area 300×230mm to 1000×750mm

The DG1 single point gap frame press is designed for reliable, high-precision stamping of metal parts. It supports automotive body panels, electronic housings, and appliance components with excellent accuracy and long-lasting performance.

With a capacity ranging from 25T to 315T and stroke speeds of 30 to 200 SPM, the single point gap frame press meets demanding production needs. The six-surface guide and high-rigidity frame provide exceptional stability during stamping, punching, cutting, and forming. Built according to Japan’s JIS grade-1 precision standards, it delivers consistent performance to keep your operations running smoothly.

- Tools: wrench grooves, pliers, screwdriver heads, hammer heads

- Kitchenware: pot lids, knives, baking trays

- Home appliances: washing machine shells, refrigerator door panels, microwave oven panels, air conditioner casings

- Hardware: hinges, locks, screws

- Electronics: smartphone frames, metal casings, circuit board brackets

- Automotive, aerospace components, and more

- High-rigidity steel frame with long-term stability

- Shot-blasting and stress-relief treatments

- Six-surface guide rails and optimized transmission for stable, accurate stamping

- Heat-treated and ground key parts including crankshafts and gears

- High-torque clutch and hydraulic overload protection for safe operation

- Inverter speed control for flexibility across stamping processes

- Automatic grease lubrication system (for 60T and above) for smooth, reliable performance

| Model | Unit | DG1-25T | DG1-35T | DG1-45T | DG1-60T | DG1-80T | DG1-110T | DG1-160T | DG1-200T | DG1-260T | DG1-315T | |||||||||||

| Type | V | H | V | H | V | H | V | H | V | V | H | V | H | V | H | V | H | V | H | |||

| Capacity | T | 25 | 36 | 45 | 60 | 80 | 110 | 160 | 200 | 260 | 315 | |||||||||||

| Rated tonnage point | mm | 3.2 | 1.6 | 3.2 | 1.6 | 3.2 | 1.6 | 4 | 2 | 4 | 2 | 6 | 3 | 6 | 3 | 6 | 3 | 7 | 3.5 | 7 | 3.5 | |

| Strokes per minute | Variable speed | S.P.M | 60- 140 | 130- 200 | 40- 120 | 110- 180 | 40- 100 | 110- 150 | 35- 90 | 80- 120 | 35- 80 | 80- 120 | 30- 60 | 60- 90 | 20- 50 | 40- 70 | 20- 50 | 50- 70 | 20- 40 | 40- 50 | 20- 35 | 30- 50 |

| Fixed speed | S.P.M | 110 | 85 | 75 | 65 | 55 | 50 | 35 | 35 | 30 | 30 | |||||||||||

| Stroke length | mm | 60 | 30 | 70 | 40 | 80 | 50 | 120 | 60 | 150 | 70 | 180 | 80 | 200 | 90 | 200 | 100 | 250 | 150 | 250 | 150 | |

| Max. shut height | mm | 200 | 215 | 220 | 235 | 250 | 265 | 310 | 340 | 340 | 380 | 360 | 410 | 460 | 510 | 460 | 510 | 500 | 550 | 550 | 600 | |

| Die height adjustment | mm | 50 | 55 | 60 | 75 | 80 | 80 | 100 | 110 | 120 | 120 | |||||||||||

| Slide area | mm | 300×230 | 360×250 | 400×300 | 500×360 | 560×420 | 650×470 | 700×550 | 850×630 | 950×700 | 1000×750 | |||||||||||

| Slide plate thickness | mm | 50 | 50 | 60 | 70 | 70 | 80 | 90 | 90 | 100 | 110 | |||||||||||

| Bolster area | mm | 680×300 | 800×400 | 850×440 | 900×500 | 1000×550 | 1150×600 | 1250×800 | 1400×820 | 1500×840 | 1800×900 | |||||||||||

| Bolster plate thickness | mm | 70 | 70 | 80 | 80 | 90 | 110 | 140 | 160 | 180 | 200 | |||||||||||

| Die Shank hole diameter | mm | 38.1 | C38.1 | 438.1 | C50 | 050 | 050 | 65 | C65 | C65 | C65 | |||||||||||

| Main motor | kW.p | 3.7×4 | 3.7×4 | 5.5×4 | 5.5×4 | 7.5×4 | 11×4 | 15×4 | 15×4 | 18.5×4 | 30×4 | |||||||||||

| Slide adjustment mechanism | Manual | Electric | ||||||||||||||||||||

| Air pressure required | kg/cm² | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 | |||||||||||

| Precision | mm | JIS 6402 (Japan) Grade-1 | ||||||||||||||||||||

| Die cushion capacity | ton | — | 2.3 | 2.3 | 3.6 | 3.6 | 6.3 | 10 | 14 | 14 | 14 | |||||||||||

| Die cushion stroke length | mm | 50 | 50 | 70 | 70 | 80 | 80 | 100 | 100 | 100 | ||||||||||||

| Die cushion pad area | mm | — | 300×230 | 300×230 | 350×300 | 450×310 | 500×350 | 650×420 | 710×480 | 810×480 | 810×480 | |||||||||||

Standard Configurations

- Variable speed drive

- Hydraulic overload protector

- Manual slide adjustment (below 60T)

- Electrical slide adjustment (greater than 80T)

- Mechanical die height indicator (below 60T)

- Digital die height indicator (greater than 80T)

- Slide and die counterbalance system

- Electronic encoder

- Misfeed detector

- Power socket

- Human-machine control system (Defu)

- Overrun safety device

- Air ejector

- Maintenance tool box

- Operating manual

Optional Configurations

- Wet clutch

- Pneumatic die cushion

- Foot switch

- Quick die change

- Slide knockout

- Automatic uncoiler

- Intelligent manipulator

- Die area light

- Slug detector (Riken Optech Corporation)

- Tonnage monitor

- Photoelectric safety device

Designs are subject to change without prior notice and can be customized according to your requirements.

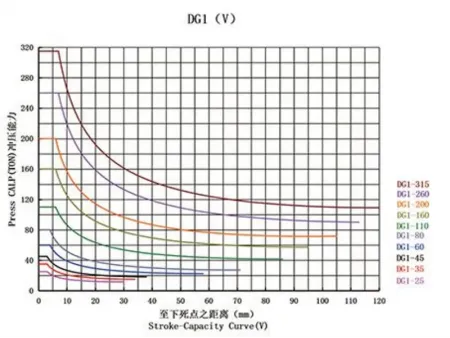

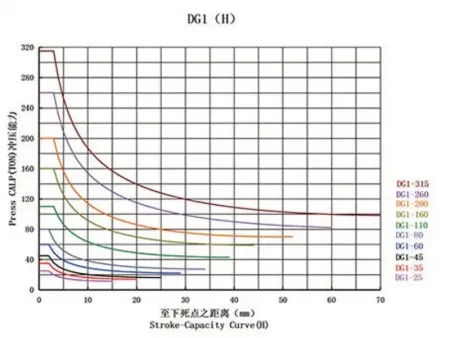

Stroke Capacity Diagram

Outline Dimensions (mm)

| Model | DG1-25 | DG1-35 | DG1-45 | DG1-60 | DG1-80 | DG1-110 | DG1-160 | DG1-200 | DG1-260 | |||||||||

| Type | V | H | V | H | V H | V | H | V | H | V | H | V | H | V H | V H | |||

| AA | 840 | 900 | 950 | 1000 | 1170 | 1290 | 1390 | 1680 | 1850 | |||||||||

| AB | 700 | 800 | 790 | 860 | 980 | 1100 | 1200 | 1400 | 1560 | |||||||||

| AC | 368 | 500 | 550 | 600 | 690 | 800 | 870 | 980 | 1050 | |||||||||

| AD | 680 | 800 | 850 | 900 | 780 | 1150 | 1250 | 1400 | 1500 | |||||||||

| AE | 408 | 488 | 502 | 526 | 544 | 616 | 660 | 800 | 900 | |||||||||

| AF | 300 | 360 | 400 | 500 | 560 | 650 | 700 | 850 | 950 | |||||||||

| AG | 540 | 620 | 670 | 720 | 780 | 920 | 1000 | 1160 | 1300 | |||||||||

| AH | 920 | 990 | 1040 | 1090 | 1328 | 1458 | 1559 | 1790 | 1945 | |||||||||

| BA | 1150 | 1200 | 1400 | 1420 | 1595 | 1720 | 2140 | 2440 | 2615 | |||||||||

| BB | 910 | 1050 | 1250 | 1220 | 1295 | 1320 | 1740 | 1880 | 2005 | |||||||||

| BC | 1390 | 1450 | 1650 | 1670 | 1820 | 1970 | 2390 | 2690 | 2865 | |||||||||

| HA | 715 | 702 | 702 | 700 | 732 | 711 | 752 | 826 | 802 | |||||||||

| HB | 795 | 790 | 790 | 785 | 830 | 830 | 900 | 995 | 1030 | |||||||||

| HC | 200 | 215 | 220 | 235 | 250 | 265 | 310 | 340 | 340 | 380 | 360 | 410 | 460 | 510 | 460 | 510 | 500 | 550 |

| HD | 60 | 30 | 70 | 40 | 80 | 50 | 120 | 60 | 150 | 70 | 180 | 80 | 200 | 90 | 200 | 100 | 250150 | |

| HE | 2125 | 2300 | 2390 | 2750 | 2980 | 3133 | 3610 | 4058 | 4433 | |||||||||

| HF | 1462 | 1461 | 1638 | 1614 | 1638 | |||||||||||||

| ØH | Ø18 | Ø18 | Ø23 | Ø23 | Ø28 | Ø28 | Ø35 | Ø33 | Ø40 | |||||||||

Bolster & Slide Plate Dimensions

| Model | A | B | C | D | E | F | H | I | J | K | L | T-slot |

| DG1-25 | 240 | 120 | 90 | 680 | 300 | 300 | 230 | / | 150 | Ø38 | 80 | I |

| DG1-35 | 280 | 140 | 120 | 800 | 400 | 360 | 250 | / | 160 | Ø38 | 100 | I |

| DG1-45 | 300 | 150 | 120 | 850 | 440 | 400 | 300 | / | 210 | Ø38 | 120 | I |

| DG1-60 | 320 | 160 | 150 | 900 | 500 | 500 | 360 | 220 | 220 | Ø50 | 160 | Ⅱ |

| DG1-80 | 360 | 180 | 150 | 1000 | 550 | 560 | 420 | 300 | 220 | Ø50 | 180 | Ⅱ |

| DG1-110 | 400 | 200 | 160 | 1150 | 600 | 650 | 470 | 300 | 220 | Ø50 | 220 | Ⅱ |

| DG1-160 | 440 | 220 | 220 | 1250 | 800 | 700 | 550 | 300 | 175 | Ø65 | 220 | Ⅱ |

| DG1-200 | 480 | 240 | 280 | 1400 | 820 | 850 | 630 | 420 | 200 | Ø65 | 300 | Ⅱ |

| DG1-260 | 520 | 260 | 290 | 1500 | 840 | 950 | 700 | 420 | 200 | Ø65 | 300 | Ⅱ |

| DG1-315 | 520 | 260 | 290 | 1800 | 900 | 1000 | 750 | 450 | 200 | Ø65 | 300 | Ⅱ |

Our product brochure

The single point gap frame press brings precision, stability, and efficiency to your production line. Contact us to learn more and get the right solution for your applications.