Heat Insulated UPVC Hollow Sheet

1. Exceptional Heat and Sound Insulation Performance

2. Supporting up to 1300mm purlin spacing

3. High Strength and 100% Waterproof

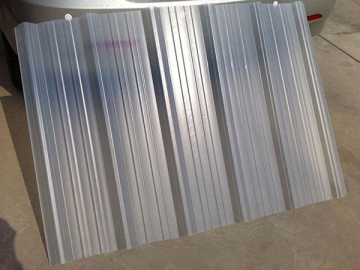

The Heat Insulated UPVC Hollow Sheet is especially new designed by our company to offer increased strength and rigidity as well as extended lifespan. As compared with conventional roofing sheets, The reinforced version supports purlin spacing up to 1300mm, which saves lots of cost in steel structure construction. The same as our common products.

The insulated UPVC hollow sheet is a ideal heat and sound insulating roofing materials for use in corrosive or high temperature areas. They also create a sense of space and beauty. They are suitable for use in countries and areas with varied climate conditions, including the Middle East, Africa, Asia, and more.

The reinforced UPVC hollow sheet is often used in places with certain thermal or sound insulating requirements balcony, car sheds, and more. As well as buildings such as chemical factories, warehouses, prefab houses, farmers markets, and more.

Factory

Factory Shop

Shop

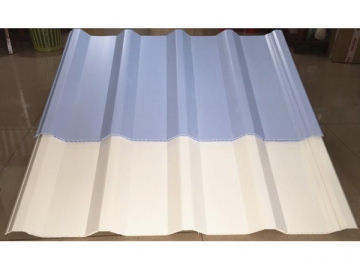

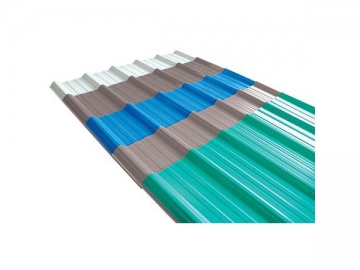

White, blue, green, beige, grey, or customized.

White

White

(RURT-C-001) Blue

Blue

(RURT-C-002) Green

Green

(RURT-C-003) Beige (light yellow)

Beige (light yellow)

(RURT-C-004) Grey

Grey

(RURT-C-006)

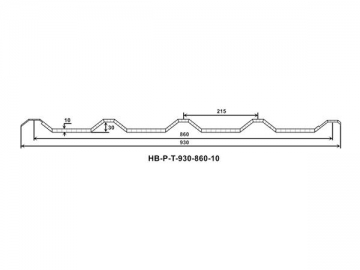

| Model | HB-URT | ||||||

| Profile |  | ||||||

| Thickness | 10mm | ||||||

| Purlin Span | 1300mm | ||||||

| Length | 5800mm, 11800mm or Customizable | ||||||

| Overall Width | 930mm | ||||||

| Effective Width | 860mm | ||||||

| Slope | > 20° | ||||||

| Weight | 4.50 kg/m2 | ||||||

| Container Load Capacity | SQ.M./20 FCL (21 Tons) | SQ.M./20 FCL (26 Tons) | |||||

| 2500 m2 | 5000 m2 | ||||||

| No. | Test item | Test method | Test condition | Test result | |

| 1 | Tensile strength | ASTM D638-10 | Testing speed: 50mm/min | 26Mpa | |

| 2 | Flexural strength | ASTM D790-10 Procedure A | Testing speed: 1.3mm/min Span: 48mm | 52Mpa | |

| 3 | Temperature different between outdoor and indoor | 10℃ | |||

| 4 | Impact resistance | ASTM D5420-10 | Geometry: GE(Ø12.70mm) Impact weight: 0.9kg | Mean failure energy: 4J | |

| 5 | High temperature resistance | 60°C , 6h | No visible change | ||

| 6 | Low temperature resistance | -35°C , 6h | No visible change | ||

| 7 | Chemical resistance | 70% Ethanol solution, (V/V), Immersion test, 23°C, 2h | No visible change | ||

| 8 | 10% NaOH Solution,(m/m), Immersion test, 23°C, 2h | No visible change | |||

| 9 | Saturation NaCL Solution, Immersion test, 23°C, 2h | No visible change | |||

| 10 | Thermal conductivity | ASTM C518-10 | Mean temperature (°C) | Temperature difference (°C) | Thermal conductivity [W/(m.K)] |

| 25.48 | 9.36 | 0.071 | |||

| 11 | 20mm Vertical burning test | UL 94-2013 Section 8 | Specimen: 129x12.5x3.0mm | V-0 | |

| 12 | Sound | Compare with metal roof tile | 30 dB lower | ||

Note: The above testing results are achieved based on 3mm thick and tests conducted by SGS and are provided for reference only.

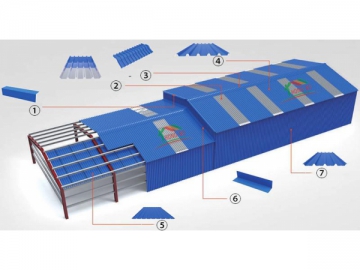

1. Barge Board

2. Tranparent Roofing Sheet

3. Ridge Unit

4. Roofing Sheet

5. Celling

6. Sidewall Flashing

7. Wall Cladding

These special waterproof installation accessories are independently designed by us for proper installation and fixation of our UPVC Hollow Sheet. They play important roles in fixing the sheeting materials properly. Thus avoiding water leakage and distortion as well as other unusual circumstances.We recommend using 5 sets of fittings for every square meter of roofing sheet during installation. So as to prevent water leakage and extend the service life of the roofing material.