UPVC Roofing Sheet (T-1130)

1. Exceptional Heat and Sound Insulation Performance

2. Competitive Pricing

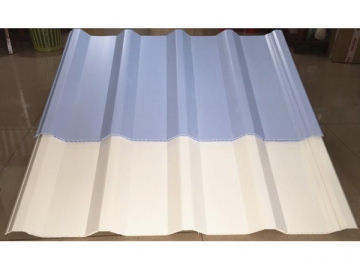

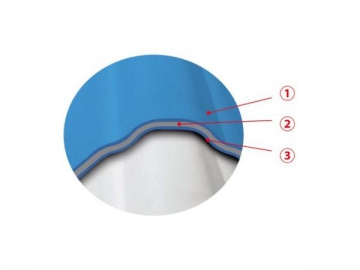

The 3 layer heat insulated UPVC roofing sheet is manufactured based on 3 layer co-extrusion technology by one-time processing. It is an ideal building material for construction projects with heat insulation requirement. The following is a list of the distinct features of each layer of material.

- Weather resistant resin is selected as the top layer material to block the solar ultraviolet radiation and reduce the coefficient of heat conductivity. It provides our UPVC roofing material with great durability and chemical corrosion resistance.

- The middle layer is a special foam structure with heat and sound insulation performances.

- The bottom layer of our heat insulated UPVC roof sheet adopts modified PVC material to offer optimum strength and rigidity.

Due to the above three kinds of materials, our insulated UPVC sheets become an ideal heat and sound insulating roofing material for use in corrosive or high temperature areas. They also create a sense of space and beauty. They are suitable for use in countries and areas with varied climate conditions, including the Middle East, Africa, Asia, and more.

The 3 layer co-extruded UPVC roofing sheet is often used in places with certain thermal or sound insulating requirements, including balcony, car sheds, and more. It is a popular construction material for flat roof to pitched roof renovation projects, as well as buildings such as chemical factories, warehouses, prefab houses, farmers markets, and more. Additionally, this kind of sheeting material can be utilized as wall panels.

Industrial Park Project

Industrial Park Project Workshop

Workshop

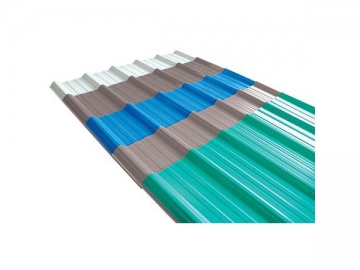

White, blue, green, beige, grey, or customized.

White

White

(URT-C-001) Blue

Blue

(URT-C-002) Green

Green

(URT-C-003) Beige (light yellow)

Beige (light yellow)

(URT-C-004) Grey

Grey

(URT-C-006)

| Model | HB-URT | ||||||

| Profile |  | ||||||

| Thickness | 1.5mm | 1.8mm | 2.0mm | 2.5mm | 3.0mm | ||

| Purlin Span | 600mm | 650mm | 700mm | 800mm | 900mm | ||

| Length | 5800mm, 11800mm or Customizable | ||||||

| Overall Width | 1130mm | ||||||

| Effective Width | 1050mm | ||||||

| Slope | > 20° | ||||||

| Weight | 2.0mm: 3.70 kg/m2 | 2.5mm: 4.70 kg/m2 | 3.0mm: 5.70 kg/m2 | ||||

| Container Load Capacity | Thickness | SQ.M./20 FCL (21 Tons) | SQ.M./20 FCL (26 Tons) | ||||

| 1.5mm | 7300 m2 | 9100 m2 | |||||

| 1.8mm | 6200 m2 | 7700 m2 | |||||

| 2.0mm | 5600 m2 | 7200 m2 | |||||

| 2.5mm | 4400 m2 | 5600 m2 | |||||

| 3.0mm | 3600 m2 | 4600 m2 | |||||

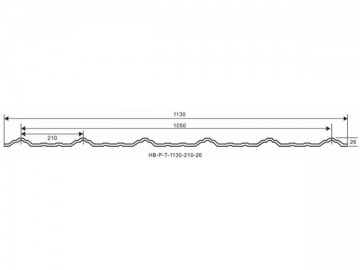

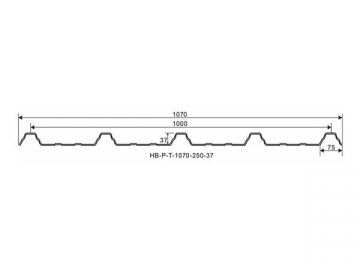

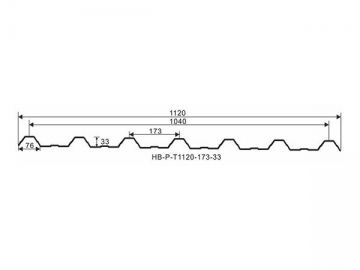

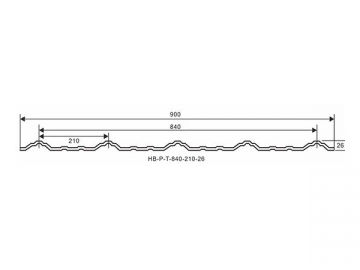

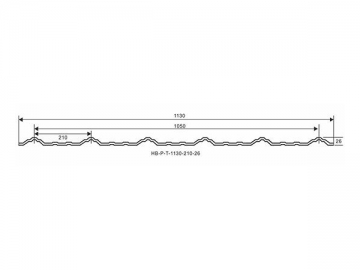

| Profile Type | Model No. | Profile Drawing |

| Trapezoidal (reinforced type ) | HB-P-T-1070-250-37 ( recommended ) |  |

| HB-P-T-1120-173-33 ( recommended ) |  | |

| Trapezoidal | HB-P-T-840-210-26 |  |

| HB-P-T-1130-210-26 |  | |

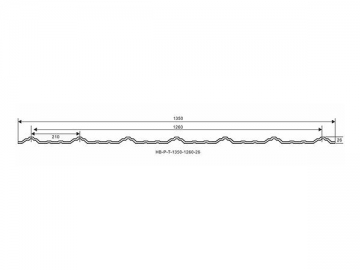

| HB-P-T-1350-210-26 ( recommended ) |  | |

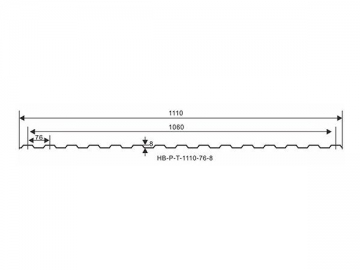

| Trapezium (utilized as wall panel) | HB-P-T-1110-76-8 |  |

| HB-P-T-1410-76-8 | ||

| Round Wave | HB-P-T-930-63-16 | |

| HB-P-T-1130-63-16 |

| No. | Test item | Test method | Test condition | Test result | |

| 1 | Tensile strength | ASTM D638-10 | Testing speed: 50mm/min | 26 Mpa | |

| 2 | Flexural strength | ASTM D790-10 Procedure A | Testing speed: 1.3mm/min Span: 48mm | 52 Mpa | |

| 3 | Temperature different between outdoor and indoor | 8℃ | |||

| 4 | Impact resistance | ASTM D5420-10 | Geometry: GE(Ø12.70mm) Impact weight: 0.9kg | Mean failure energy: 4J | |

| 5 | High temperature resistance | 60°C , 6h | No visible change | ||

| 6 | Low temperature resistance | -35°C , 6h | No visible change | ||

| 7 | Chemical resistance | 70% Ethanol solution, (V/V), Immersion test, 23°C, 2h | No visible change | ||

| 8 | 10% NaOH Solution,(m/m), Immersion test, 23°C, 2h | No visible change | |||

| 9 | Saturation NaCL Solution, Immersion test, 23°C, 2h | No visible change | |||

| 10 | Thermal conductivity | ASTM C518-10 | Mean temperature (°C ) | Temperature difference (°C ) | Thermal conductivity [W/(m.K )] |

| 25.48 | 9.36 | 0.071 | |||

| 11 | 20mm Vertical burning test | UL 94-2013 Section 8 | Specimen: 129x12.5x3.0mm | V-0 | |

| 12 | Sound | Compare with metal roof tile | 30 dB lower | ||

Note: The above testing results are achieved based on 3mm thick and tests conducted by SGS and are provided for reference only.

Superior heat insulation performance

With fabulous heat insulation performance, our UPVC roofing sheet offers heat conductivity coefficient of 0.07W/(m.K), which is only 1/6 that of cement tiles and 1/2200 that of 0.5mm thick color steel tiles.

Good sound insulation performance

By absorbing the sound, this range of UPVC roof panel is soundproof. Its sound insulation effect is 35dB higher than color steel sheets.

Highly corrosion resistant

Due to exceptional corrosion resistance, the product comes without any chemical reactions even when it is immersed in the saline solution, alkali solution, or the acid solution with concentration below 60% for continuously 24 hours. Unlike color steel sheets, this plastic sheeting material won't rust, so it is able to avoid water-leakage problems.

Splendid water resistance

The unique external design, coupled with our patented waterproof fittings, makes sure all the fastening screws won't rust. This is one of the reasons why our heat insulated UPVC roofing sheet has superb water resistance.

- Special Waterproof Fittings

- Application Project

Good fire-resistant rating

Our UPVC roofing sheets have undergone fire resistance testing conducted by SGS according to UL 94-2013 standard. The testing proves our products have high flame rating (≥V0), and are ideal nonflammable building material.

Highly efficient installation

The light weight and complete range of installation accessories make our heat insulated UPVC roofing sheet easy for installation. The maximum effective width (for standard products only) up to 1260mm ensures higher installation efficiency and reduced installation cost as well.

1. Barge Board

2. Tranparent Roofing Sheet

3. Ridge Unit

4. Roofing Sheet

5. Celling

6. Sidewall Flashing

7. Wall Cladding

These special waterproof installation accessories are independently designed by us for proper installation and fixation of our UPVC Roofing Sheet. They play important roles in fixing the sheeting materials properly. Thus avoiding water leakage and distortion as well as other unusual circumstances.We recommend using 5 sets of fittings for every square meter of roofing sheet during installation. So as to prevent water leakage and extend the service life of the roofing material.