Transparent UPVC Roofing Sheet

This product has been discontinued and removed from our shelves.

Special Features

1. Competitively Priced

2. Excellent Anti-UV Performance

The transparent UPVC roofing sheet is manufactured based on the latest technologies and European standard PVC resin formulations. It adopts PVC as the main material which is then mixed with anti-UV additive and other chemical additives. The quality material makes the plastic roofing sheet weather resistant and compatible with acid and alkali as well as organic solvents. Other advantages are listed below.

UPVC Roofing Sheet Features

(1) Competitively priced

(2) Fire resistant and waterproof

(3) Highly corrosion resistant

(4) Easy for installation due to lightweight

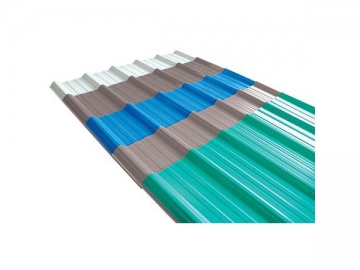

(5) Light transmitting and multiple color options

(6) High strength

Applications of Transparent UPVC Roofing Sheet

The transparent design makes the UPVC roofing sheet a great material for green houses, skylights, as well as various roofing projects with daylighting demands. Meanwhile, the same as our other series of UPVC roofing materials, this range of product is also regularly used in the roof construction projects for chemical factories, warehouses, steel structure buildings, vegetable markets, car sheds, etc.

Green House

Green House Factory

Factory

| Model | HB-TURT | ||

| Thickness | 1.0 ±0.1mm | 1.2 ±0.1mm | 1.5 ±0.1mm |

| Weight | 1.7 ±0.1kg/m2 | 2.1 ±0.1kg/m2 | 2.6 ±0.1kg/m2 |

| Length | 5800mm , 11800mm or can be customized | ||

| Overall width | 1130 mm | 1350mm | Varies with the profile type |

| Effective width | 1050 mm | 1260mm | Varies with the profile type |

| Purlin spacing | 700~800mm | ||

| Color | White-transparent, blue-transparent, green-transparent, or customized | ||

| Container Load capacity | Thickness | SQ.M./20 FCL (21 Tons) | SQ.M./40 FCL (26 Tons) |

| 1.0mm | 12000 m2 | 15000 m2 | |

| 1.2mm | 10000 m2 | 12300 m2 | |

| 1.5mm | 8000 m2 | 10000 m2 | |

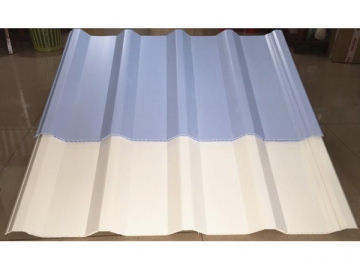

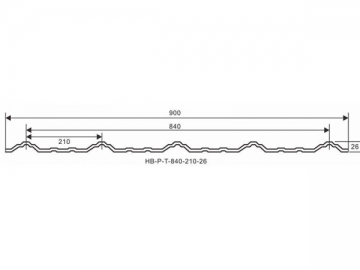

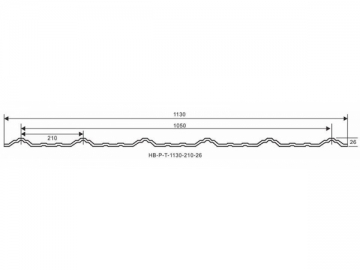

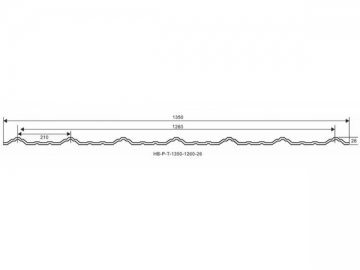

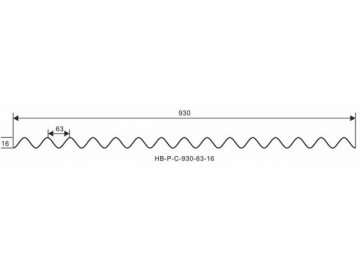

| Product Type | Model No. | Profile Drawing |

| Trapezoidal | HB-P-T-840-210-26 |  |

| HB-P-T-1130-210-26 |  | |

| HB-P-T-1350-210-26 (recommended) |  | |

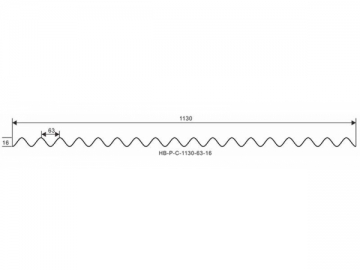

| Round Wave | HB-P-T-930-63-16 |  |

| HB-P-T-1130-63-16 |  |

| No. | Test item | Test method | Test condition | Test result |

| 1 | Tensile strength | ASTM D638-10 | Testing speed: 50mm/min | 46 Mpa |

| 2 | Flexural strength | ASTM D790-10 Procedure A | Testing speed: 1.3mm/min Span: 48mm | 68 Mpa |

| 3 | High temperature resistance | --- | 60°C , 6h | No visible change |

| 4 | Low temperature resistance | --- | -35°C , 6h | No visible change |

| 5 | Chemical resistance | --- | 70% Ethanol solution,(V/V), Immersion test, 23°C, 2h | No visible change |

| 6 | --- | 10% NaOH Solution, (m/m), Immersion test, 23°C, 2h | No visible change | |

| 7 | --- | Saturation NaCL Solution, Immersion test, 23°C, 2h | No visible change | |

| 8 | 20mm Vertical burning test | UL 94-2013 Section 8 | Specimen: 129x12.5x3.0mm | V-0 |

| 9 | Purlin Spacing | --- | Spacing between 2 purlins | 700~800mm |

Note: The above testing results are achieved based on 3mm thick and tests conducted by SGS and are provided for reference only.

Related Names

Plastic Roof Panel | Transparent Roof Material | UPVC Sheeting Material | Building Material