Aluminum Alloys for Heat Transfer

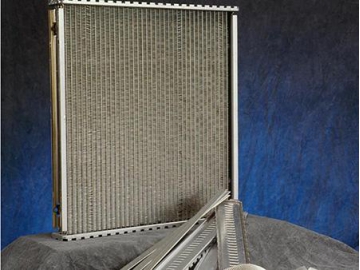

Heat transfer devices, or radiators are applied in industrial processes to transfer heat away from the equipment through a transference in a fluid medium. This keeps the equipment at an optimal operating temperature. The most common materials for heat transfer devices are copper and aluminum because of their good thermal conductivity. DLS Aluminum can provide many kinds of aluminum alloys for application in heat transfer applications, and they offer the following features:

①Low weight and high strength

Cooling devices in heat transfer industry usually need lightweight and high-strength materials, and aluminum meets both requirements. The strength to weight ratio of aluminum is better than steel, brass and copper, and the cost is lower.

②Ease of processing

Aluminum alloy has high ductility and low melting temperature, so it is ideal for extruding and casting. Aluminum alloy can be processed into almost any shape by extrusion machine, which makes the design of the aluminum radiator more diversified.

| Alloy | Status | Tensile strength(MPa) | Yield strength Rp0.2 (MPa) | Elongation (%) |

| 5083 aluminum plate | H321 | ≥305 | ≥215 | ≥12 |

| 5083 aluminum plate | O | 275~350 | ≥125 | ≥16 |

| 6082 aluminum plate | T6/T651 | ≥300 | ≥255 | ≥9< |