Composite Aluminum

Composite aluminum are composed of two or more aluminum alloy materials with different properties. Various aluminum alloys can complement one another in performance and produce synergistic effect, making the comprehensive performance of aluminum alloy composites better than single aluminum alloy. Therefore, aluminum alloy composites can meet higher demands, which makes it the ideal materials in oil, construction, aerospace, vehicle and electronics industries.

DLS Aluminum has developed many special aluminum alloy composites for the following industries, and you can use without any problem. Our research center can also customize aluminum alloy composites which are best for you according to your practical demands.

Products: Composite aluminum tubes, plates, fins

Grades: F1A6, F416, F8B6, F8A61, F116, F466, F116B

Alloy status: H16, H14, O, H24

Applications: Used for water tanks, intercoolers, condensers, evaporators, heaters and oil coolers

Features: Composite aluminum alloy has excellent welding and processing performance. It can make radiators have much lighter weight and longer service life. It can meet various demands of automotive heat exchangers for the mechanical property, brazing property, processability, corrosion resistance and thermal conductivity of materials.

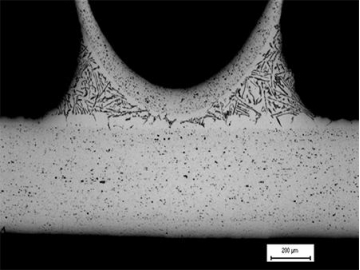

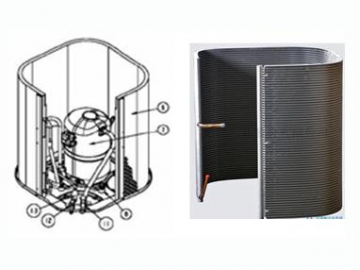

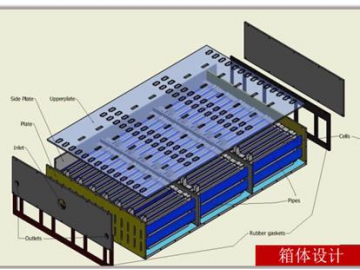

Products: Aluminum alloy composite plates, tubes, fins, collecting pipes

Grades: F416, F416A, F113D, 8H33, F653

Alloy status: H16, H14, H24

Applications: Used in brazed heat exchangers of refrigeration equipment, household air conditioners, commercial air conditioners and central air conditioners

Features: Composite aluminum alloy shows better performance than traditional aluminum alloy materials in thermal conductivity, machinability, brazing property and corrosion resistance. Besides, it can meet the demand of new refrigerant CO2.

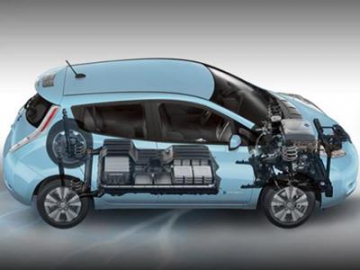

Products: Aluminum alloy composite plates

Applications: Used for lithium battery cases of electric vehicles

Features: It can ensure the effective heat dissipation of battery, and also lower the vehicle weight and save fuel consumption.

We will keep long-term business cooperation with electric vehicle manufacturers such as BMW and Tesla, and lithium battery manufacturers, and will provide guarantee for your production with preferential cooperation mode.

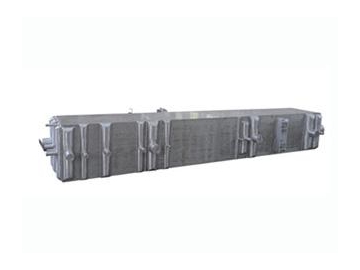

Products: Aluminum alloy composite plates, fins

Applications: Used for heat exchangers in air separation system. Air separation system is used to separate oxygen, nitrogen and argon out of air, and composite aluminum alloy is required for heat exchange. This has very high demand for the strength, weldability and corrosion resistance of heat exchangers. DLS Aluminum can provide you with various composite aluminum alloys with high strength, excellent weldability and good thermal conductivity, which can completely satisfy your requirements in air separation system field.

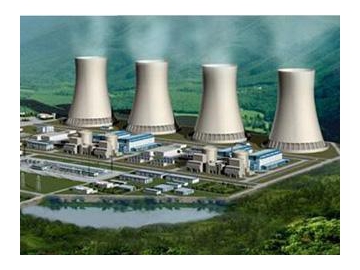

Products: Aluminum alloy composite fins

Applications: Used for cold end of steam turbines and air-cooled radiators in power stations

DLS Aluminum has rich experience in the design and production of heat transferring aluminum alloy, and can provide you with various aluminum composites used in air cooled systems in power stations. Our products have good thermal conductivity, corrosion resistance and weldability, which can meet the demands of cold end of steam turbines and air-cooled radiators for corresponding materials.

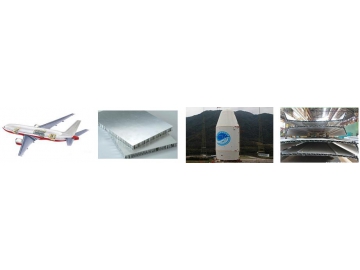

Products: Aluminum alloy composite plates, fins

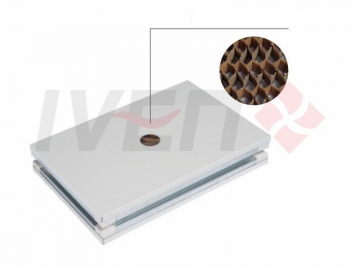

Applications: Used for the fairing of rockets and satellites, the wings and vertical tails of planes, rail vehicle body and construction materials.

DLS Aluminum can provide you with various honeycomb aluminum composite panels, each of which is composed of two high-strength skins and central thick and light honeycomb core. They show excellent performance in strength, weldability, impact resistance and formability.