Tube and Sheet Laser Cutter with Shuttle Platform,GS-CEG Laser Cutter 3 Axis CNC Laser Cutting Machine

Request a Quote

The GS-CEG laser cutter is able to cut tubes and sheets with no extra costs associated with the purchase of two machines, as well as saving the space occupied by two machines. No additional configurations are needed to complete changeover between tubes and sheets, which maximizes the working efficiency. The double platform design allows one platform to operation, while the other simultaneously feeds materials, thus increasing the working efficiency.

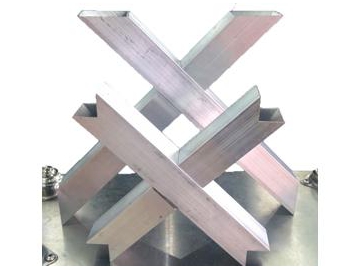

Cutting samples- The machine body is treated with high-temperature annealing, ensuring long-term use without deformation.

- Driven by precision gear rack and linear guideway, the laser cutter features a high precision, high efficiency and stability.

- The cutting head is equipped with protective glasses to reduce the consumption of valuable consumables like focus lenses and other parts.

- The focal length is automatically adjustable according to the material surface flatness. The cutting effect is not influenced by an uneven surface.

- A hand-held controller is equipped to manually adjust the cutting position.

- The use of a high quality servo motor and reducer ensures the processing speed and accuracy.

| Model | GS-3015CEG | GS-4015CEG | GS-4020CEG | GS-6020CEG | |

| Laser power | 500W-4000W (Optional) | 500W-4000W (Optional) | 500W-4000W (Optional) | 500W-4000W (Optional) | |

| Work area | 3000*1500mm | 4000*1500mm | 4000*2000mm | 6000*2000mm | |

| X-axis stroke | 1530mm | 1530 | 2030 | 2030 | |

| Y-axis stroke | 3050mm | 4050 | 4050 | 6050 | |

| Z-axis stroke | 340mm | 340mm | 340mm | 340mm | |

| undefinedX/Y axis geometric positioning accuracy | ≤0.05mm (full range) | ≤0.05mm (full range) | ≤0.05mm (full range) | ≤0.05mm (full range) | |

| X/Y axis repeated positioning accuracy | ≤0.03mm | ≤0.03mm | ≤0.03mm | ≤0.03mm | |

| Cutting pipe length | 3000&6000mm | ||||

| Chuck cutting size | Manual Chuck | φ20-φ190mm/φ20-φ220mm/φ20-φ340mm | |||

| Automatic Chuck | φ20-φ120mm/φ20-φ220mm/φ20-φ340mm | ||||

| Machine size | 8700*3800*2000mm/ 9050*3800*2000mm | 10900*3800*2000mm/ 10900*3800*2000mm | 10900*4370*2000mm/ 10900*4370*2000mm | 15100*3800*2000mm/ 15100*3800*2000mm | |