GS-TG Tube/Pipe Laser Cutting Machine

Request a Quote

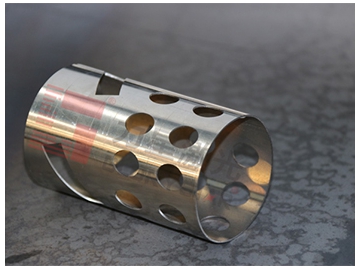

GS-TG is the professional pipe & tube cutting machine. It is suitable for all tubes, pipes and shaped-tubes, including round tube, square pipe, oval tube, angle iron, channel beams, H beams, T beams and other irregularly shaped tubes. Compared with traditional tube cutting machine, it can increase the working efficiency and reduce the procedures of manual operations by optional functions automatic loading.

Cutting samples- Automatic loading material device: To increase the working efficiency and reduce workforce cost.

- With double automatic chucking, it is convenient to clamp the pipes and the clamping force is adjustable according to the pipe wall thickness.

- The long roller allows for clamping angle iron, H beam, U beam steel, and other open type pipe.

- With automatic edge finding and centering functions, good cutting quality for shaped materials is ensured.

| Model | GS-6012TG | GS-6022TG | GS-6034TG |

| Processing format (L/W) | 6000mm x φ120-20mm 6000mm x □120-20mm Standard profiles with a circumcircle <φ120mm | 6000mm x φ220-20mm 6000mm x £220mm-20mm Standard profiles with a circumcircle <φ120mm | 6000mm x φ340-20mm 6000mm x □240mm-20mm Standard profiles with a circumcircle <φ120mm |

| X-axis stroke | 500mm | 500mm | 500mm |

| Y-axis stroke | 7000mm | 7000mm | 7000mm |

| Z-axis stroke | 400mm | 400mm | 400mm |

| W-axis | Infinite rotation (133RPM) | Infinite rotation (100RPM) | Infinite rotation (100RPM) |

| Max. X/Y axis positioning speed | 80m/min | 60m/min | 60m/min |

| Max. X/Y axis acceleration | 1.0G | 0.5G | 0.3G |

| X/Y axis geometric positioning accuracy | ≤0.1mm (full range) | ≤0.05mm (full range) | ≤0.05mm (full range) |

| X/Y axis repeated positioning accuracy | ≤0.05mm | ≤0.03mm | ≤0.03mm |

| Max Tube weight | 20Kg/M | 20Kg/M | 20Kg/M |

| Machine size (L x W x H ) | 10380mmx2000mmx2500mm | 10380mmx2000mmx2500mm | 10380mmx2000mmx2500mm |

- Full-automatic feeding device: put the tubes with the same specification on the coil belt for automatic feeding. This enhances working efficiency and saves labor costs.

- Auxiliary receiving device: When cutting longer parts, the auxiliary receiving device automatically extends the feeding device to hold the tubes.

- Zero-tailing cutting device: when it is cutting the last section of material, the front chuck moves forward and the rear chuck also moves forward to shorten the tailing as much as possible.

- Upgrading software packages: through an upgrade to the software package, box iron, angle iron, H beam, and other tube shape cutting is available.