D Frame Stamping Press (80-315 Tons), APD Series

High Performance Stamping Press | Automobile Metal Stamping Industry | 80 - 315 Tons Capacity

The APD series D frame stamping presses are semi-closed high precision steel press machines that are safe, convenient and reliable. These punching presses feature a slide block adjustment that is precise to within 0.1mm. The semi-closed structure of the stamping press adds to the stability of the machine during operation and helps to load and discharge work pieces. The sheet metal forming machine is widely used for the production of electronics, household appliances, furniture, performance tools and other metal parts that require stamping and forming.

1. The stamping press for home appliances is constructed with a highly rigid steel frame which can withstand the internal stresses that occur during stamping processes. This leads to greater precision and reliability.

2.A consistent driving center and machine center guarantee accurate and stable punching.

3.Two balancing devices are installed to keep the machine stable during any operation.

4.Mold-adjustment precision is as accurate to within 0.1mm and is safe, speedy, and reliable.

5.Through hard oxidation and grinding, parts such as axles, gear sets, and connecting rods have a higher stress tolerance.

6. The metalworking machine has a highly sensitive and reliable clutch/brake and top duplex magnetic valve, as well as overload protection devices, to guarantee precision and safety during operation.

7.The D frame stamping press's structural design is built for convenience and automatic production, reducing cost, and improving efficiency.

8.Advanced design concepts lead to low noise, low consumption, and energy savings.

1.Frequency converter

2.Oil pressure overload protection device

3.Electric slide adjustment device

4.Die height indicator

5.Slide and mold balancing device

6.Misfeed detection device

7.Power socket

8.Crank angle indicator

9.Counter

10.Air source connector

11.Over-run safety device

12.Maintenance tool and tool box

1.Electric lubricating device

2.Air die cushion device

3.Preset counter

4.Foot switch

5.Rapid mold exchanging device (Die lifter, die clamper, or mold-shift arm)

6.Upper slider feeding device

7.Anti-vibration foot

8.Photo-electric safety device

9.Feeder (air, machinery, and NC)

10.Feeding rack

11.Straightening machine

12.Manipulator

13.Mould lighting device

14.Left (right) feeding device

15.PAC100 control system

16.Man-machine control system

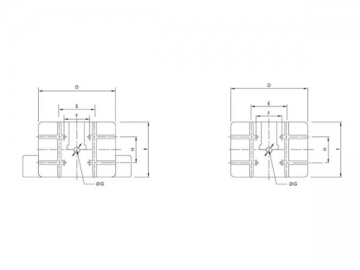

| Model | A | B | C | D | E | F | G | H | I |

| APD-80 | 360 | 180 | 150 | 560 | 300 | 220 | 050 | 180 | 420 |

| APD-110 | 400 | 200 | 160 | 650 | 300 | 220 | 050 | 220 | 470 |

| APD-160 | 440 | 220 | 220 | 700 | 300 | 175 | 065 | 220 | 550 |

| APD-200 | 480 | 240 | 280 | 850 | 420 | 200 | 065 | 300 | 630 |

| APD-260 | 520 | 260 | 290 | 950 | 420 | 200 | 065 | 300 | 700 |

| APD-315 | 540 | 280 | 300 | 1000 | 450 | 200 | 065 | 300 | 750 |

| Name | Unit | APD-80 | APD-110 | APD-160 | APD-200 | APD-260 | APD-315 | ||||||

| Model | V type | H type | V type | H type | V type | H type | V type | H type | V type | H type | V type | H type | |

| Capacity | Ton | 80 | 110 | 160 | 200 | 260 | 315 | ||||||

| Rated tonnage point | mm | 4 | 2 | 6 | 3 | 6 | 3 | 6 | 3 | 7 | 3.5 | 7 | 3.5 |

| Stroke | mm | 150 | 70 | 180 | 80 | 200 | 90 | 200 | 100 | 250 | 150 | 280 | 170 |

| Die height | mm | 340 | 380 | 360 | 410 | 460 | 510 | 460 | 510 | 500 | 550 | 550 | 600 |

| Stroke per minute | s.p.m | 35-80 | 80-120 | 30-60 | 60-90 | 20-50 | 40-70 | 20-50 | 50-70 | 20-40 | 40-50 | 20-35 | 30-50 |

| Slide adjustment | mm | 80 | 80 | 100 | 110 | 120 | 120 | ||||||

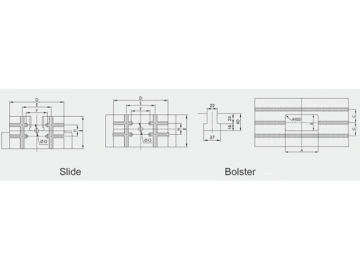

| Slide area | mm | 560×420×70 | 650×470×80 | 700×550×90 | 850×630×90 | 950×700×100 | 1000×750×110 | ||||||

| Bolster area | mm | 760×550×90 | 900×600×110 | 980×880×140 | 1140×820×160 | 1500×840×180 | 1600×900×200 | ||||||

| Main motor | kwxp | 7.5×4 | 11×4 | 15×4 | 18×4 | 22×4 | 30×4 | ||||||

| Slide adjust device | HP | Electric driving | |||||||||||

| Air pressure | kg/cm2 | 6 | 6 | 6 | 6 | 6 | 6 | ||||||

| Press dimension(H×W×H) | mm | 1300×1890×3000 | 1420×1985×3200 | 1600×2200×3500 | 1750×2500×3900 | 2080×2895×4470 | 2100×2925×4550 | ||||||

| Press weight | Ton | 7.8 | 10.5 | 17.8 | 25.3 | 37 | 42 | ||||||

| Press precision | GB(JIS)1class | ||||||||||||

| Die cushion capacity | Ton | 3.6 | 6.3 | 10 | 14 | 14 | 14 | ||||||

| Stroke | mm | 70 | 80 | 80 | 100 | 100 | 100 | ||||||

| Die cushion effective area | mm2 | 450×310 | 500×350 | 650×420 | 710×480 | 810×480 | 810×480 | ||||||

Download PDF