C Frame Stamping Press (25-65 Tons), APL Series

Mechanical Press | Sheet Metal Forming Processes | 25 - 65 Metric Tons Capacity

The APL series C frame stamping press is a high speed, high capacity precision power press, designed for the production of large batches of small electronics components. The sheet metal forming machine is perfect for automated production systems for manufacturers of computer parts, home appliances, motors and other small precision stamping parts. These high speed presses are produced in 3 different models for you to choose: APL-25, APL-45 and APL-65.

1. The stamping press for home appliances benefits from an extended working life of the punch and mold under a power balance device.

2. Oil-Pressure slider fixed lock and a sticking release device can

increase reliability.

3. A cylinder connecting rod driven device enhances the stability of the punching machine’s operation and precision.

1.Variable-speed motor

2.Hydraulic lock punch

3.Slider and mold balancing device

4.Die height indicator

5.Slide adjust device

6.Microcomputer control cabinet

7.Operation box

8.Forced circulation oil device

9.Mechanical crank angle indicator

10.Miss-feed circuit and plug/socket(2 sets)

11.Air source connector

12.Operating manual

13.Tool box

1.Anti-vibration device

2.Oil lubricating device

3.Bottom dead center detector

4.Quick die change device

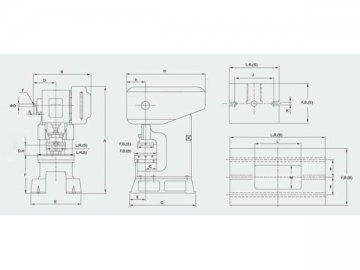

| Model | A | B | C | D | E | F | G/g | H/h | I | K×J | L×M | O | T(W×d×s) |

| APL-25 | 2040 | 1067 | 195 | 416 | 860 | 835 | 1170/360 | 1354/353 | 100 | 14×200 | 260×120 | Φ60×95L | 15×5×66 |

| APL-45 | 2300 | 1214 | 225 | 496 | 1100 | 850 | 1555/400 | 1747/403 | 120 | 18×180 | 400×180 | Φ60×95L | 15×5×66 |

| APL-65 | 2538 | 1358 | 260 | 530 | 1180 | 900 | 1555/380 | 1850/443 | 160 | 23×360 | 420×220 | Φ60×90L | 15×5×88 |

| Name | Unit | APL-25 | APL-45 | APL-65 | ||||||

| Model | A | B | C | A | B | C | A | B | C | |

| Capacity | ton | 25 | 45 | 65 | ||||||

| Rated tonnage point(B.D.C) | mm | 1.2 | 1.2 | 1.6 | ||||||

| Stroke | mm | 20 | 30 | 40 | 20 | 30 | 40 | 20 | 30 | 40 |

| Stroke per minute | s,p.m | 100-600 | 100-500 | 100-400 | 100-500 | 100-400 | 100-300 | 100-400 | 100-350 | 100-300 |

| Die height(SDAU) | mm | 225 | 220 | 215 | 265 | 260 | 255 | 305 | 300 | 295 |

| Bolster area(L.R.×F.B.) | mm | 650×390×75 | 760×450×90 | 860×520×100 | ||||||

| Slide area(LR.×F.B.) | mm | 280×250 | 380×320 | 460×370 | ||||||

| Slide adjustment | mm | 30 | 30 | 50 | ||||||

| Main motor | Kw | 3.7×4P | 5.5×4P | 7.5×4P | ||||||

| Shank hole | mm | 038.1 | 050 | 050 | ||||||

| Disc hole(L.R.×F.B.) | mm | 270×150 | 400×200 | 480×260 | ||||||

| Lubrication system | Forced circulating lubrication | |||||||||

Download PDF