Stamping Press (15-315 Tons), APA Series

High Precision Press | Metal Stamping Industry | 15 - 315 Metric Tons Capacity

The APA series of high precision stamping press is a powerful metalworking machine with stamping capacity from 15-315 tons. This incredibly powerful stamping press equipment is suitable for variety of different manufacturing applications such as sheet metal punching, forming and extension. These metal forming processes are used to produce vehicles, watches, household appliances, hand tools and electronics among many other goods.

Extra-long precision six-point box type gibbing

These gibbing pieces ensure that the sliding pieces of the machine move accurately remain secure. Since the force of the punching press is delivered vertically, minimizing lateral movement is absolutely crucial. The box type gibs keep the clearance settings of the machines at a stable minimal level with the aid of laminated spacers.

Super rigid steel frame

The APA series stamping press is designed to resist deflection and to produce accurate pressings, leading to longer die life, even at full tonnage loads. The heavy, one-piece welded steel frame undergoes rigorous stress treatments to withstand even the most demanding loads during operation.

Highly responsive

Our fast response hydraulic overload protection system (HOLP) will relieve the pressure of a tonnage overload in milliseconds, causing the press to immediately stop, preventing damage to the power press and the surrounding workers. The hydraulic pressure of the system can be reconfigured by pushing the reset button on the control console.

High performance wet clutch and brake

The clutch of the power press machine delivers high torque at relatively low air pressure and angular mass. The clutch and brake friction linings are high performance features with low vibration and noise. The linings operate in an enclosed oil bath, providing highly effective heat dissipation. The combination of these features greatly extends the working life of the machine and significantly improves performance even under heavy repeated operation.

Convenient die cushion installation

The compact design of the die cushion facilitates simple removal and replacement as it is bolted to the bolster with clear access for the user.

1. Frequency converter

2. Oil pressure overload protection device

3. Manual slide adjustment device (60Tons and below)

4. Electric slide adjustment device (80Tons and above)

5. Mechanical die height indicator (60Tons and below)

6. Electric die height indicator (60Tons and above)

7. Slide and mould balancing device

8. Rotary cam switch

9. Misfeed detection device

10. Power socket

11. Crank angle indicator

12. Electrical stroke counter

13. Air source connector

14. Over-run safety device

15. Air jetting device

16. Maintenance tool box

17. Operation manual

1. Wet clutch brake

2. Electrical lubrication system

3. Pneumatic die cushion device

4. Foot switch

5. Quick die change device (Die lifter, die clamper, or mould-shift arm)

6. Upper slide feeding device

7. Anti-vibration foot

8. Photo-electronic safety device

9. Feeder (air, machinery, and NC)

10. Feeding rack

11. Straightening machine

12. Manipulator

13. Mould lighting device

14. Touch screen (preset counter, total counter)

15. PAC 100 control system

16. Man-machine control system

| Specifications | APA-25 | APA-35 | APA-45 | APA-60 | APA-80 | APA-110 | APA-160 | APA-200 | APA-260 | APA-315 |

| A | 1100 | 1200 | 1400 | 1420 | 1595 | 1720 | 2140 | 2440 | 2605 | 2605 |

| B | 840 | 900 | 950 | 1000 | 1170 | 1290 | 1390 | 1690 | 1850 | 1870 |

| C | 2135 | 2345 | 2425 | 2780 | 2980 | 3195 | 3670 | 4075 | 4470 | 4490 |

| D | 680 | 800 | 850 | 900 | 1000 | 1150 | 1250 | 1400 | 1500 | 1500 |

| E | 300 | 400 | 440 | 500 | 550 | 600 | 800 | 820 | 840 | 840 |

| F | 470 | 520 | 560 | 700 | 770 | 910 | 990 | 1130 | 1130 | 1130 |

| G | 250 | 285 | 340 | 400 | 420 | 470 | 550 | 630 | 700 | 700 |

| H | 800 | 790 | 800 | 795 | 830 | 830 | 910 | 1030 | 1030 | 1030 |

| I | 260 | 290 | 320 | 420 | 480 | 530 | 650 | 650 | 750 | 770 |

| J | 444 | 488 | 502 | 526 | 534 | 616 | 660 | 790 | 900 | 900 |

| K | 160 | 205 | 225 | 255 | 280 | 305 | 405 | 415 | 430 | 430 |

| L | 980 | 1040 | 1170 | 1180 | 1310 | 1420 | 1760 | 2040 | 2005 | 2005 |

| M | 700 | 800 | 840 | 890 | 980 | 1100 | 1200 | 1400 | 1560 | 1580 |

| N | 540 | 620 | 670 | 720 | 780 | 920 | 1000 | 1160 | 1300 | 1320 |

| 0 | 1275 | 1375 | 1575 | 1595 | 1770 | 1895 | 2315 | 2615 | 2780 | 2780 |

| P | 278 | 278 | 313 | 333 | 448 | 488 | 545 | 593 | 688 | 688 |

| Q | 447 | 560 | 585 | 610 | 620 | 685 | 725 | 805 | 875 | 885 |

| R | 935 | 1073 | 1130 | 1378 | 1506 | 1650 | 1960 | 2188 | 2460 | 2480 |

| Name | Unit | APA-15 | APA-25A | APA-25 | APA-35 | APA-45 | APA-60 | APA-80 | APA-110 | APA-160 | APA-200 | APA-260 | APA-315 | ||||||||||

| Model | V type | V type | V type | H type | V type | H type | V type | H type | V type | H type | V type | H type | V type | H type | V type | H type | V type | H type | V type | H type | V type | H type | |

| Capacity | Ton | 15 | 25 | 25 | 35 | 45 | 60 | 80 | 110 | 160 | 200 | 260 | 315 | ||||||||||

| Rated tonnage point | mm | 1 | 3.2 | 3.2 | 1.6 | 3.2 | 1.6 | 3.2 | 1.6 | 4 | 2 | 4 | 2 | 6 | 3 | 6 | 3 | 6 | 3 | 7 | 3.5 | 7 | 3.5 |

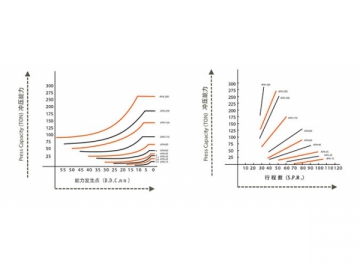

| Variable speed | s.p.m | 120-180 | 60-140 | 60-140 | 130-200 | 40-120 | 110-180 | 40-100 | 100-150 | 35 - 90 | 80-120 | 35-80 | 80-120 | 30-60 | 60-90 | 20-50 | 40-70 | 20-50 | 50-70 | 20-40 | 40-50 | 20-35 | 35-50 |

| Constant speed | s.p.m | 130 | 110 | 110 | 85 | 75 | 65 | 65 | 50 | 35 | 35 | 30 | 30 | ||||||||||

| Stroke | mm | 60 | 80 | 60 | 30 | 70 | 40 | 80 | 50 | 120 | 60 | 150 | 70 | 180 | 80 | 200 | 90 | 200 | 100 | 250 | 150 | 280 | 170 |

| Die height | mm | 200 | 195 | 200 | 215 | 220 | 235 | 250 | 265 | 310 | 340 | 340 | 380 | 360 | 410 | 460 | 510 | 460 | 510 | 500 | 550 | 550 | 600 |

| Slide adjustment | mm | 50 | 50 | 50 | 55 | 60 | 75 | 80 | 80 | 100 | 110 | 120 | 120 | ||||||||||

| Slide area | mm | 300×230×50 | 300×230×50 | 300×230×50 | 360×250×50 | 400×300×60 | 500×360×70 | 560×420×70 | 650×470×80 | 700×550×90 | 850×630×90 | 950×700×100 | 1130×750×110 | ||||||||||

| Bolster area | mm | 680×300×70 | 680×300×65 | 680×300×70 | 800×400×70 | 850×440×80 | 900×500×80 | 1000×550×90 | 1150×600×110 | 1250×800×140 | 1400×820×160 | 1500×840×180 | 1600×900×200 | ||||||||||

| Shank hole | mm | 038.1 | 038.1 | 038.1 | 038.1 | 038.1 | 050 | 050 | 050 | 065 | 065 | 065 | 065 | ||||||||||

| Main motor | kw.p | 2.2×6 | 3.7×4 | 3.7×4 | 3.7×4 | 5.5×4 | 5.5×4 | 7.5×4 | 11×4 | 15×4 | 18×4 | 22×4 | 30×4 | ||||||||||

| Slide adjust mechanism | HP | Manual operation | Electric driving | ||||||||||||||||||||

| Air pressure | kg/cm2 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | ||||||||||

| Press precision | GB(JIS)1 class | GB(JIS)1 class | GB(JIS)1class | GB(JIS)1class | GB(JIS)1class | GB(JIS)1 class | GB(JIS)1class | GB(JIS)1class | GB(JIS)1 class | GB(JIS)1class | GB(JIS)1class | GB(JIS)1class | |||||||||||

| Press dimension(H×W×H) | mm | 1236×830×1920 | 1280×850×2200 | 1280×850×2200 | 1380×900×2400 | 1575×950×2500 | 1595×1000×2800 | 1800×1180×2980 | 1900×1300×3200 | 2315×1400×3670 | 2615×1690×4075 | 2780×1850×4470 | 2870×1980×4830 | ||||||||||

| Press weight | Tons | 1.8 | 2.1 | 2.1 | 3 | 3.8 | 5.6 | 6.5 | 9.6 | 16 | 23 | 32 | 36 | ||||||||||

| Die cushion capacity | Ton | - | - | - | 2.3 | 2.3 | 3.6 | 3.6 | 6.3 | 10 | 14 | 14 | 14 | ||||||||||

| Die cushion stroke | mm | - | - | - | 50 | 50 | 70 | 70 | 80 | 80 | 100 | 100 | 100 | ||||||||||

| Die cushion effective area | mm2 | - | - | - | 300×230 | 300×230 | 350×300 | 450×310 | 500×350 | 650×420 | 710×480 | 810×480 | 810×480 | ||||||||||

Download PDF

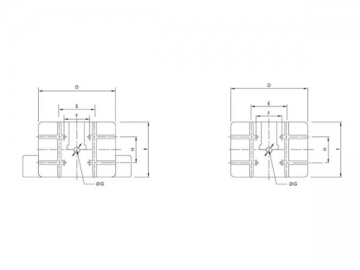

Slide Bolster

Bolster

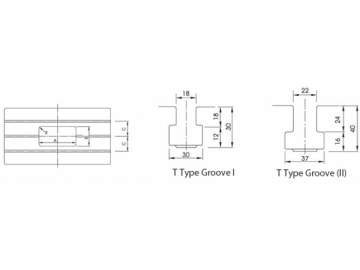

| Model | A | B | C | D | E | F | G | H | I | T type groove |

| APA-15 | 240 | 120 | 90 | 300 | - | 150 | Φ 38.1 | 80 | 230 | Ⅰ |

| APA-25A | 240 | 120 | 90 | 300 | - | 150 | Φ 38.1 | 80 | 230 | Ⅰ |

| APA-25 | 240 | 120 | 90 | 300 | - | 150 | Φ 38.1 | 80 | 230 | Ⅰ |

| APA-35 | 280 | 140 | 120 | 360 | - | 160 | Φ 38.1 | 100 | 250 | Ⅰ |

| APA-45 | 300 | 150 | 120 | 400 | - | 210 | Φ 38.1 | 120 | 300 | Ⅰ |

| APA-60 | 320 | 160 | 150 | 500 | 220 | 220 | Φ 50 | 160 | 360 | II |

| APA-80 | 360 | 180 | 150 | 560 | 300 | 220 | Φ 50 | 180 | 420 | II |

| APA-110 | 400 | 200 | 160 | 650 | 300 | 220 | Φ 50 | 220 | 470 | II |

| APA-160 | 440 | 220 | 220 | 700 | 300 | 175 | Φ 65 | 220 | 550 | II |

| APA-200 | 480 | 240 | 280 | 850 | 420 | 200 | Φ 65 | 300 | 630 | II |

| APA-260 | 520 | 260 | 290 | 950 | 420 | 200 | Φ 65 | 300 | 700 | II |

| APA-315 | 520 | 260 | 290 | 950 | 420 | 200 | Φ 65 | 300 | 700 | II |