C Frame Stamping Press (25-60 Tons), API Series

High Speed Press Machine | Stamping Press for Home Appliances | 25 - 60 Metric Tons Capacity

Our API series C frame stamping press is one of our most popular lines of high precision punching machine because of its high speed processing ability. The precision and speed of the metal stamping press make it ideal for producing large quantities of small electronic parts for computers, appliances, motors and other small precision sheet metal stamping parts. This series consists of three models, the API-25, API-45 and API-60 power press machine.

1. The structure of the C frame stamping press is produced using a high strength casting process to guarantee long term precision.

2. The metal forming machine's three-circle guide pillar slider structure is made from alloy steel and utilizes forced lubrication to keep wear parts intact for extended periods of use as well as to regulate temperature.

3. A dynamic equilibrium system is used to balance axles and minimize vibration generated when the slider runs to control stability.

4. Manual mold height adjustment is equipped with a mold height indicator and oil-pressure clamping device.

5. Intelligent interface (electronic cam rotary encoder) operation is convenient and highly accurate.

6. Operating functions are shown on an LCD display.

7. Highly sensitive and reliable clutch/brake and top duplex magnetic valve, guarantee precision and safety for operation.

8. With a thorough electric loop design, our mechanical press machine can be matched with various automatic devices, to reduce cost and improve efficiency.

1.Top stop device

2.Manual slide adjust device

3.Die height indicator

4.Frequency converter

5.Programmable controller (PLC)

6.Touch screen (pre-set, total count, angle indicator)

7.Encoder (electronic), reserved 2 groups

8.Operation box

9.Air source connector

10.Mold disconnecting device

11.Main motor (adjustable speed)

12.Mode locking device

13.Mechanical crank angle indicator

14.Forced circulation oil device

15.Tool box

16.Operating manual

17.Power socket

18.Independent electric control cabinet

1.Anti-vibration foot

2.Feeder

3.Feeding rack

4.Oil lubricating device

5.Bottom dead center detector

6.Oil cooler

7.Mold light

8.Air jetting device

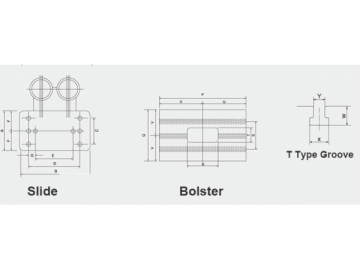

| Model | A | B | C | D | E | F | G | P | Q | R | S | T | U | V | W | X | Y |

| API-25 | 205 | 300 | 150 | 212 | 190 | 102.5 | 25 | 600 | 300 | 200 | 180 | 100 | 300 | 150 | 30 | 30 | 18 |

| API-45 | 320 | 420 | 150 | 340 | 260 | 160 | 40 | 700 | 415 | 240 | 240 | 120 | 350 | 205 | 40 | 37 | 22 |

| API-60 | 340 | 550 | 240 | 360 | 300 | 170 | 40 | 840 | 470 | 320 | 270 | 160 | 420 | 235 | 40 | 37 | 22 |

| Name | Unit | API-25 | API-45 | API -60 | |||

| Model | A | B | A | B | A | B | |

| Capacity | ton | 25 | 45 | 60 | |||

| Stroke | mm | 30 | 30 | 30 | |||

| Stroke per minute | s.p.m | 200-600 | 200-800 | 200-500 | 200-700 | 200-400 | 200-600 |

| Die height | mm | 210 | 230 | 305 | |||

| Bolster | mm | 600×300×80 | 700×415×100 | 840×470×105 | |||

| Area of slide | mm | 300×205 | 420×320 | 550×340 | |||

| Slide adjustment | mm | 30 | 30 | 30 | |||

| Bed opening | mm | 200×100 | 240×120 | 320×160 | |||

| Motor | Kw | 3.7 | 5.5 | 7.5 | |||

| Gross weight | kg | 3000 | 4500 | 8000 | |||

| Lubrication | Forceful Automation | Forceful Automation | Forceful Automation | ||||

| Speed control | Inverter | Inverter | Inverter | ||||

| Clutch & brake | Air & Friction | Air & Friction | Air & Friction | ||||

| Top stop device | Standard | Standard | Standard | ||||

| Anti-vibration system | Optional | Optional | Optional | ||||

Download PDF