Calcium Aluminate

Mainly applied for secondary refining of ferrous metallurgy, the calcium aluminate is a must for producing top-quality steels, featuring uniform composition, low fusing point, fast smelting speed, good ability to shorten smelting time and so on. There are two kinds of extraordinary calcium aluminates available in SHUO CHENG, namely sintered calcium aluminate and fused calcium aluminate.

Sintered Calcium Aluminate Product Number:

The sintered calcium aluminate is a new generation steel-making auxiliary series product, made from multiple materials via special processing technologies. The sintered calcium aluminate contains over 90% Al2O3 and CaO, boasting fast smelting, low gas content, high activity coefficient (over 70), fast slag-making speed, early appearance of white slag, great mobility after smelting, amazing ability to adsorb most deoxidation and desulfurization products in molten steel. The sintered calcium aluminate is ideal for shortening refining time, reducing steel-making cost and achieving the goal to decrease the content of detrimental impurity and purify molten steel composition.

| Chemical component (%) | ||||||

| Product number | CaO | Al2O3 | SiO2 | TiO2 | Fe2O3 | MgO |

| 48-50 | 37-41 | ≤8 | ~2.5 | <3 | ~1.5 | |

| 45-48 | 39-42 | ≤8 | ~2.5 | <3 | ~1.5 | |

| 42-45 | 42-45 | ≤8 | ~2.5 | <3 | ~1.5 | |

| 32-35 | 50-53 | ~8 | ~2.5 | <3 | ~1.5 | |

Fused Calcium Aluminate Product Number:

The fused calcium aluminate incorporates uniform chemical component, low smelting point, fast smelting speed and great ability to shorten smelting time. According to numerous feedbacks from our clients, the curvilinear function of the stability in use of the fused calcium aluminate and the time is almost a straight line, avoiding many maladaptive phenomenon in metallurgical production brought by wavy and hackly curvilinear functions of medium-end and high-end products( like sintered products and products made in cupola furnace).

This refining slag is mainly used to separate sulphur, oxygen and other impurities from molten steel during steel ladle refining in LF furnace, open-hearth furnace or rotary furnace. The fused calcium aluminate is effective in decreasing the content of detrimental elements and impurities, well suitable for plain carbon steel, high-carbon steel, high and low alloy steels.

Features

1. No fluorine, no corrosion on furnace lining and steel ladle

2. Compact structure, non-absorbent, convenient for storage and transportation

3. The characteristics like relative stability and fact slag making lead to the reduction of dust pollution and comprehensively stable refining technologies.

4. No such impurities as hydrogen, nitrogen, carbon, etc.

| Chemical component (%) | |||||

| Product number | CaO | Al2O3 | SiO2 | Fe2O3 | MgO |

| 47-50 | 40-43 | ≤3 | ≤1.5 | ≤1.2 | |

| 45-55 | 38-48 | ≤8 | ≤1.5 | ≤1.2 | |

| 49-54 | 40-45 | ≤5 | ≤1.5 | ≤1.2 | |

Ultrafine Calcium Carbonate Production Line (Annual Output: 20-100 Thousand Tons)

pfcementmachinery.com

Ultrafine Calcium Carbonate Production Line (Annual Output: 20-100 Thousand Tons)

pfcementmachinery.com

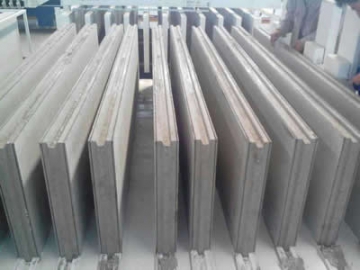

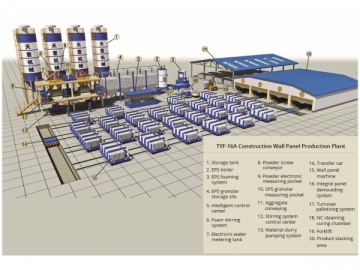

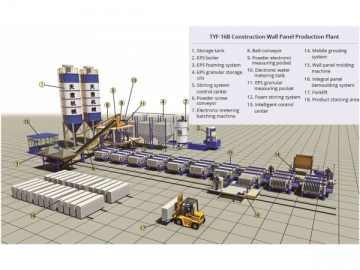

TYF-01 Construction Wall Panel Production Plant (Calcium Silicate Board Compound Wall Panel, Partition Wall)

wallpanellines.com

TYF-01 Construction Wall Panel Production Plant (Calcium Silicate Board Compound Wall Panel, Partition Wall)

wallpanellines.com