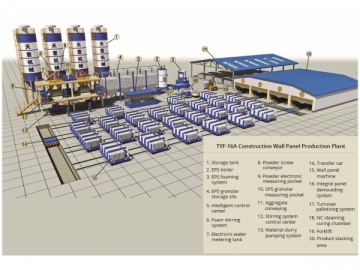

TYF-16A Construction Wall Panel Production Plant (Mobile Type, Calcium Silicate Board Compound Wall, GRC Glass Reinforced Concrete Panel)

TYF-16A horizontal construction wall panel production plant is applicable for the production of two-side calcium silicate board lightweight compound wall panel or GRC lightweight wall panel and the suitable materials include cement, fly ash, EPS polystyrene particles, sand and ceramsite. 10 pieces of panels can be molded one time.

Due to the mobility of equipment, the arrangement of production line is not easy to be limited and the line is highly automatic, which can save labor and increase production.

The whole production line is composed of automatic batching system, stirring system, foaming system, NC power distribution system, wall panel molding system, material slurry pumping system, EPS pre-foaming system, hydraulic circulating system and integral panel demoulding system.

Patent number: ZL201320713155.0

| One-time molding quantity | Thickness | Width | Length |

| 10 | 75mm | 610mm | 2440mm/3000mm |

| 10 | 90mm | ||

| 8 | 120mm | ||

| 6 | 150mm |

| One-time molding quantity | Core tube diameter | Core tubequantity | Thickness | Width | Length |

| 10 | Φ38mm | 90 | 75mm | 600/610mm | Adjustable within 3000mm |

| 10 | Φ52mm | 70 | 90mm | ||

| 8 | Φ74mm | 40 | 120mm | ||

| 6 | Φ52mm | 84 | 150mm |

Note: The above dimensions are normal ones. TANY can provide customized production lines according to your requirements for special wall panel sizes.

-

(1) TY11 prestressed wall panel machine

TY11 prestressed wall panel machine is composed of principal machine, hydraulic system, power system, heating system, vibration system and core tubes. It can move automatically and show high molding efficiency. -

(2) Stirring system

Our independently developed large stirring equipment is equipped with precise automatic batching system which can precisely feed and can also stir the slurry more uniformity based on the material properties. -

(3) Mobile grouting system

Material slurry pumping system conveys stirred slurry to equipment more uniformly and more stably, and the grouting mode is simple and convenient. -

(4) Mobile automatic stacking machine (Panel demoulding)

-

Foaming machine

The foaming system adopts frequency conversion foaming technology that can increase foaming speed and save raw materials. 40m³ foam can be produced one time.

Dimension: 1200L×800W×940H mm

Power: 2.2kW -

Transfer car

Dimension: 2000L×1300W×480H mm

Power: 2.2kW

| Overall dimension ( L×W×H) | 4030×2500×1050mm |

| Power of heating system | 18 kW |

| Power of vibration system | 0.75 kW |

| Power of hydraulic system | 3 kW |

| Hydraulic working pressure | 8 MPa |

| Maximum hydraulic working pressure | 16 MPa |

| Hydraulic oil tank volume | 60 L |

| Total area | 3500*2900mm |

| Stirring volume | 2000L |

| Stirring speed | 32.5r/min |

| Particle diameter | < 8mm |

| Powder feeding pneumatic butterfly valve | DN300 |

| Stirring period | 10-15min |

| Screw conveying power | 11 kw*2 |

| Pumping pressure in theory | High pressure | 0.5 Mpa |

| Low pressure | 0.4 Mpa | |

| Transport capacity in theory | High pressure | 5 Mpa |

| Low pressure | 9.4 Mpa | |

| Max. transport distance | Horizontal | 300 mm |

| Vertical | 120 mm | |

| Main motor power | 7.5 kW | |

| Hopper volume | 1.5m³ | |

| Loading height | 1000 mm | |

| Hydraulic oil tank volume | 80 L | |

| Distribution valve form | Ball valve | |

| Main machine weight | 500kg | |

| Frame size: L×W×H | 1785×960×1700mm | |

| Model | TY-13 |

| Overall dimension | 4500L×4600W×1050H mm |

| Total power | 7 kW |

| Demoulding motor power | 1.5 kW |

| Travel motor power | 1.5 kW |

| Hydraulic system motor power | 4 kW |

| Hydraulic working pressure | 10 Mpa |

| Maximum hydraulic working pressure | 16 Mpa |

| Stacking platform | 4500L×2300W mm |

Index

construction partition wall, precast wall panel, wall production line, interior wall machines