Light Discoloration Testing Chamber

The light discoloration testing chamber is used to determine the yellowing resistance of shoe materials when they are exposed to sunlight, and it is applicable for uppers, soles, leather, textile, PU and so on.

Features of the Light Discoloration Testing Chamber

1. Our light discoloration tester makes use of a 300W/220±10V UV lamp to offer spectral output similar to natural sunlight: ultraviolet intensity (280-400nm) of 25±0.4W/m2 with some visible light. Moreover, this lamp could work continuously for 3-24 hours, and its service life is over 1100h.

2. By using hot air circulation, the light discoloration testing chamber supports temperature adjustment up to 120°C. This temperature range is enough for general use because the most typical chamber temperature is 50±2°C.

3. Our light discoloration testing chamber is fitted with a timer which could stop the machine automatically when preset time duration (0-999h) expires, and a LCD screen is used to digitally display test temperature. In addition, the temperature accuracy is within ±2°C.

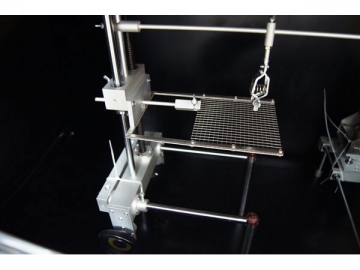

4. For this UV test chamber, there is a rotating table under the sample holder, and it drives the sample holder to rotate with it so as to provide uniform irradiance for every specimen. The rotating table has a diameter of 450mm and a rotation speed of 0-50rpm (3±1rpm is often adopted), and the distance between specimen and lamp bottom is 250±2mm.

5. A 20×20mm or larger observation window is equipped to this light discoloration tester, and it is not transparent.

Technical Data of Light Discoloration Testing Chamber

| Model | |

| Light source | 1 UV lamp |

| Temperature | Max. 120℃ |

| Heat source | Hot-air circulation |

| Insulation | Glass fiber |

| Timer | LED: 0-999hr |

| Interior dimensions | 50×50×60cm |

| Overall dimensions (W×D×H) | 88×70×56cm |

| Weight | 140kg |

| Standards | ASTM D1148, HG/T 3689 |