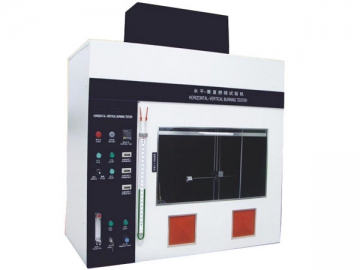

Flammability Testing Equipment (Horizontal and Vertical Flame Chamber)

Also simply called flammability tester, the flammability testing equipment is designed for the flammability testing of plastic materials used in electric devices and appliances. This selection of horizontal and vertical flame chamber is constructed of 2mm-thick cold rolled steel plates via advanced CNC machining and exterior grade powder coating processes to provide beautiful look, excellent texture and avoid the risk of discoloration, and the ASTM D5205 burner delivers stable performance while allowing easy frame height adjustment. In addition, this flammability testing equipment takes advantage of imported control components to realize safe and reliable operation.

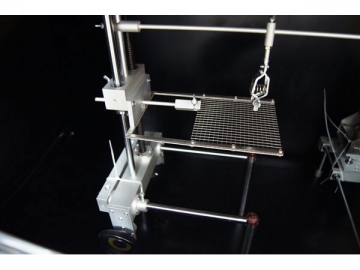

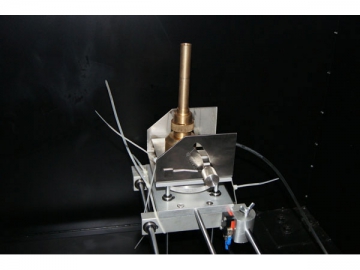

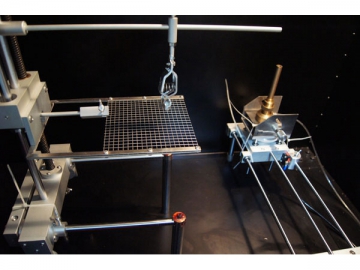

Parts Figure

Technical Data of Flammability Testing Equipment

| Model | |

| Interior dimensions (W×D×H) | 120×60×112cm |

| Exterior dimensions (W×D×H) | 120×65×150cm |

| Internal volume | 0.8m3 |

| Flame height | 15-175mm (adjustable) |

| Gas flow | 20-200ml/min (adjustable) |

| Gas pressure | 5-200mm (adjustable) |

| Flame angle | 0-45° (adjustable) |

| Burner height | 50mm |

| Vertical displacement of sample | 450mm |

| Horizontal displacement of sample | 180mm |

| Burning time | 0-99.99s (adjustable) |

| After flame time/after glow time | 0.1-99.99s (adjustable) |

| Precision | 0.01s |

| Standards | UL 94, IEC 60695-11-3, IEC 60695-11-4, ISO 9772.3, ASTM D635/3801/4804/4986 |

Major Components of Flammability Testing Equipment

| Part | Details |

| Chamber | Made from 2mm cold rolled plate via CNC forming |

| Internal light | Explosion-proof lamp (Osram or Philips 40W halogen lamp) |

| Exhaust system | Standard 180W exhaust fan |

| Viewing window | 6000×4000×5mm armored glass |

| Transmission system | Axis linear bearing drive (chrome coated) |

| Clamp | Made from imported anodized aluminum |

Related Names

Flammability Test Equipment | Plastic Testing Equipment

Environmental Testing Chamber for Humidity and Temperature Testing, Item KMH-64 Climate Simulation Chamber

climate-tester.com

Environmental Testing Chamber for Humidity and Temperature Testing, Item KMH-64 Climate Simulation Chamber

climate-tester.com

Temperature and Humidity Testing Chamber, Item KMH-800 Environment Simulation Chamber

climate-tester.com

Temperature and Humidity Testing Chamber, Item KMH-800 Environment Simulation Chamber

climate-tester.com