Auto Parts Temperature Humidity Testing Chamber

The environmental test chamber simulates specific environmental conditions for auto parts and interior accessories, such as cockpit, ashtrays, shift knobs, steering wheels and so forth.

Technical Parameters of Environmental Test Chamber for Auto Parts

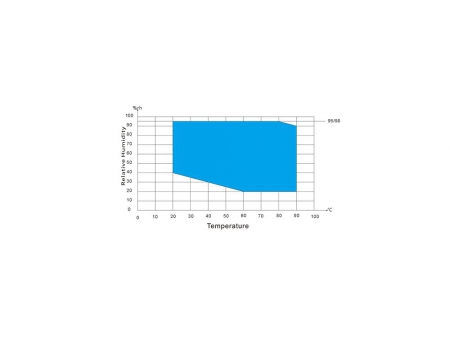

| Temperature range | -50°C to 120°C |

| Temperature deviation | ≤±2 ℃ |

| Temperature uniformity | ≤2 ℃ |

| Temperature fluctuation | ≤±0.5 ℃ |

| Heat-up speed | ≤1℃/min or customized |

| Cool-down speed | ≤0.7℃/min or customized |

| Humidity range | 20-95%rh |

| humidity deviation | ≤±5%rh |

| Humidity fluctuation | ≤±2.5%rh |

| Illumination intensity | Up to 1200W/m2; When the air temperature is 65℃, the surface temperature of sample can be controlled to 120℃. |

| Low-temperature relative humidity monitor is optional. Under low temperature, the relative humidity is ≤ 30%RH | |

| Self-programming control | |

| Without the temperature and humidity control range of active load |

| GB2423.1-2008(IEC68-2-1:2007) | Environmental Testing - Part 2: Test Methods - Tests A: Cold |

| PV2005 Plan A 2000 Edition | |

| PV1200 2004 Edition | |

| PR308.2 2006 | Edition (70℃ 95%RH, 105℃) |

| GB2423.2-2008 | (IEC68-2-2:2007) Environmental Testing - Part 2: Test Methods - Tests B: Dry Heat |

| GB2423.3-2006(IEC68-2-78:2001) | Environmental Testing for Electric and Electronic Products - Part 2: Testing Method Test Cab: Damp Heat, Steady State |

| GB2423.4-2008(IEC68-2-30:2005) | Environmental Testing for Electric and Electronic Products - Part 2: Test Method - Test Db: Damp Heat, Cyclic |

| GJB150.3A-2009 | Laboratory Environmental Test Methods for Military Materiel-Part 3: High Temperature Test |

| GJB150.4A-2009 | Laboratory Environmental Test Methods for Military Materiel-Part 4: Low Temperature Test |

| GJB150.4A-2009 | Laboratory Environmental Test Methods for Military Materiel-Part 4: Low Temperature Test |

| GJB899-90 | Reliability Testing for Qualification and Production Acceptance |

| GJB1032-90 | Environmental Stress Screening Process for Electronic Products |

| GB10589-2008 | Specifications for Low Temperature Test Chambers |

| GB11158-2008 | Specifications for High Temperature Test Chambers |

| GB10586-2006 | Specifications for Damp Heat Testing Chambers |

The duct structure of auto parts temperature humidity testing chamber has gained a patent for invention. The duct structure ensures that the temperature in each testing area of the test chamber is uniform, thus guaranteeing higher test accuracy.

Oil separator and oil returning and shunting device: The oil contained in the high-pressure steam discharged by refrigeration compressor is separated to ensure safe and efficient operation of the refrigeration system. Oil returning and shunting device (Simplewell’s patented technology) is mainly used to ensure the long-term operation of compressor or operation in high temperature. It prevents compressor failure or shortening of compressor service life due to lack of oil.