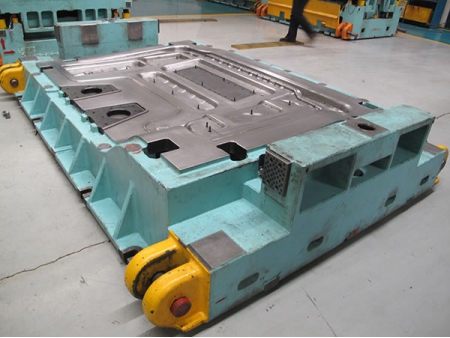

Stamping Die for Car Fender

Featured on this page is the stamping die for car fenders. Though they appear to be simple, car fenders are actually complex parts, due to the fact that there are several joint areas to which car attachments are connected using clips, nuts, screws and rivets. Because of that, the quality of a company's car fender auto die can significantly reflect their tooling capability.

The draw die that we produce stretches a plat panel into a 3D shape in a fast and precise manner. Different materials can be used to construct the upper and lower dies, and the blank holder. Below, we have listed several types.

Upper die: Mocr, blank holder: H300, nose of upper die (punch): Mocr, lower die: H300

Upper die: H300, nose of punch: H300, inserts: SKDII or Cr12MoV, blank holder: H300, lower die: H300

Note that there are guide posts on all four corners of the draw die, guiding the movement of the upper die.

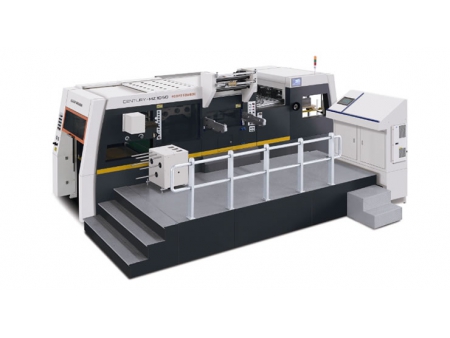

The cam trim die removes excess parts from the edge of the work piece. Key factors in this process include locating the stamping die section and components in the proper locations on the die shoe, and a fast tool changeover between vertical and angled cuts.

Both the driver's side fender and the passenger's side fender are produced in a single stamping die. Because of that, the two fenders need to be separated from each other in the cut off die.

This step is critical in forming the right profile on the finished car fender.

Flanging and forming operations are not always done perpendicular to the working surface. This is why the side cam die is so important to carrying out the bending and flanging at virtually any angle. During this process, it is critical to precisely locate and secure the work piece.

Car fenders are not flat panels. Holes need to be made in different planes, and finding the right spot to do the right piercing is key to this.

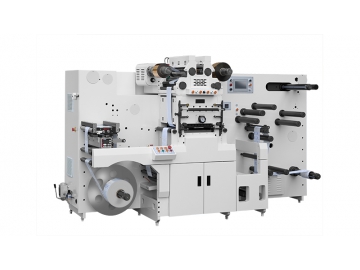

Stamping Die and Car Fender Showcase

Finished Products