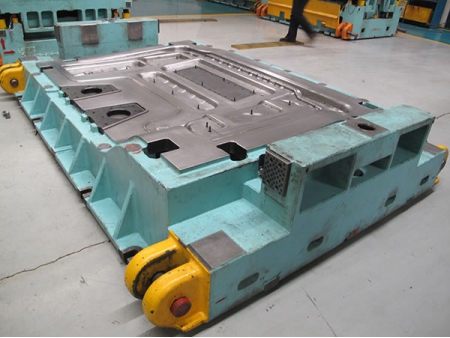

Stamping Die for Car Door Panel

When we talk about the car door panel, we are specifically referring to the interior side of the car door. Featured on this page is the front door panel for an electric bus produced using our stamping die.

This auto die is made from welded plates that are twice as thick, and involve different processes, including drawing, trimming, piercing, flanging, forming and cam piercing. Both the driver and passenger side car door panels can be made in one stamping die simultaneously, saving tooling costs.

Each draw die is built with the customer's need in mind. The material choice depends on specific applications, make and model of the car. Below are popular options.

Upper die: Mocr, blank holder: H300, nose of upper die (punch): Mocr, lower die: H300

Upper die: H300, nose of punch: H300, inserts: SKDII or Cr12MoV, blank holder: H300, lower die: H300

-

Trimming is a process where additional and binder materials are cut off and removed from the trimming die. Trimming operations are performed perpendicular to the working surface, making it easier to carry out.

Benefits of this forming die include easy maintenance, low cost, and maximum reliability.

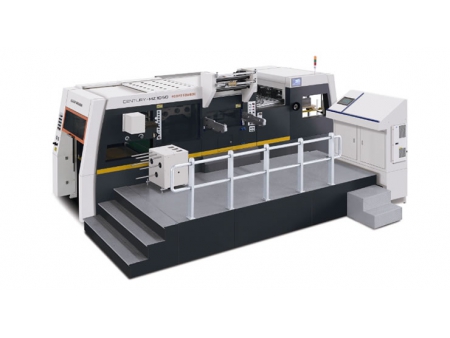

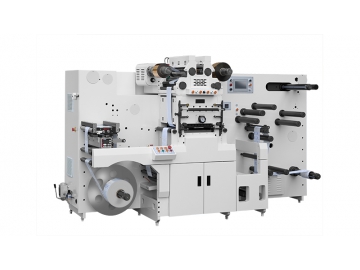

Sample Showcase

Finished Products