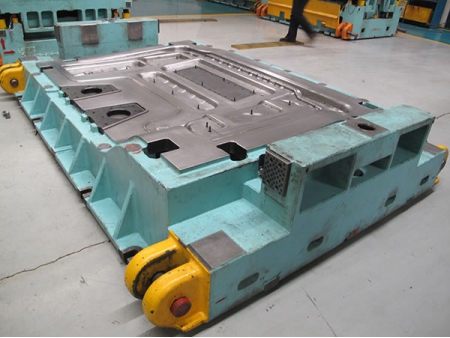

Stamping Die for Car Hood / Bonnet

The stamping die is generally associated with the automotive industry, as many outer car panels are made from steel using the stamping process. When stamping performance and accuracy are required in your car part manufacturing, Huanghe is a trusted stamping die designer and manufacturer. Our valued customers include car manufacturers, auto part producers and car dealerships.

A large car panel, such as the bonnet, requires more than one die to complete necessary operations. The draw die is the first step of the stamping process. Made from trapezoid shaped blanks, the deep draw die can achieve great depth while ensuring the rigidity of the finished drawn parts. A unique knock-out rod design eliminates the need to adjust the knock out rod of the stamping press, making installation easier.

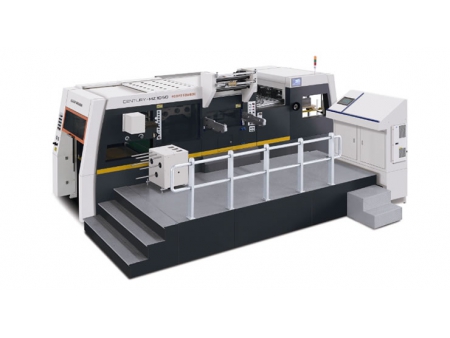

The trimming andpiercing die is specially designed for easy removal of scraps and trimmed pieces as well as to locate and hold components down in their exact positions. The automated knockout rod is pneumatically powered, pushing finished parts from the die.

The flanging process is a crucial step to car hood manufacturing, as the flanges around the edge of the car hood make it easier for users to install and weld the part where it is supposed to be installed. Several issues need to be taken into consideration during flanging, including the flanging sequence and changeover between tools.