CSD Harmonic Drive Speed Reducer

Request a Quote

Application

Walking shaft of robot, gantry robot of machine tool, SCARA, wafer handing robot, stamping equipment, pipe bender, take-out robot for injection molding, turret of machine tool rotating, x and y axes of machine tool, indexing table drive, pulley for loading machine, belt drive of axis input, tension tester, automated guided vehicle, robot for high-speed working, rolling up, rotating, conveying, angle control, double axis control, inspection device of printed circuit board, stamping

Technical Parameters

CSD-2UH | Model | Ratio | Rated torque of input speed 2000r/min | Max. torque of starting to stop | Max. torque of average load | Instant Max.torque | Max.input speed r/min | Average input speed r/min | Moment of inertia | |||||||

| Nm | kgfm | Nm | kgfm | Nm | kgfm | Nm | kgfm | Grease lubrication | Grease lubrication | I X10-4kgm² | J X10-5kgfms² | ||||

| 14 | 50 | 3.7 | 0.38 | 12 | 1.2 | 4.8 | 0.49 | 24 | 2.4 | 8500 | 3500 | 0.021 | 0.021 | ||

| 100 | 5.4 | 0.55 | 19 | 1.9 | 7.7 | 0.79 | 35 | 3.6 | |||||||

| 17 | 50 | 11 | 1.1 | 23 | 2.3 | 18 | 1.9 | 48 | 4.9 | 7300 | 3500 | 0.054 | 0.055 | ||

| 100 | 16 | 1.6 | 37 | 3.8 | 27 | 2.8 | 71 | 7.2 | |||||||

| 20 | 50 | 17 | 1.7 | 39 | 4.0 | 24 | 2.4 | 69 | 7.0 | 6500 | 3500 | 0.09 | 0.092 | ||

| 100 | 28 | 2.9 | 57 | 5.8 | 34 | 3.5 | 95 | 9.7 | |||||||

| 160 | 28 | 2.9 | 64 | 6.5 | 34 | 3.5 | 95 | 9.7 | |||||||

| 25 | 50 | 27 | 2.8 | 69 | 7.0 | 38 | 3.9 | 127 | 13 | 5600 | 3500 | 0.282 | 0.288 | ||

| 100 | 47 | 4.8 | 110 | 11 | 75 | 7.6 | 184 | 19 | |||||||

| 160 | 47 | 4.8 | 123 | 13 | 75 | 7.6 | 204 | 21 | |||||||

| 32 | 50 | 53 | 5.4 | 151 | 15 | 75 | 7.6 | 268 | 27 | 4800 | 3500 | 1.09 | 1.11 | ||

| 100 | 96 | 10 | 233 | 24 | 151 | 15 | 420 | 43 | |||||||

| 160 | 96 | 10 | 261 | 27 | 151 | 15 | 445 | 45 | |||||||

| 40 | 50 | 96 | 10 | 281 | 29 | 137 | 14 | 480 | 49 | 4000 | 3000 | 2.85 | 2.91 | ||

| 100 | 185 | 19 | 398 | 41 | 260 | 27 | 700 | 71 | |||||||

| 160 | 206 | 21 | 453 | 46 | 316 | 32 | 765 | 78 | |||||||

| 50 | 50 | 172 | 18 | 500 | 51 | 247 | 25 | 1000 | 102 | 3500 | 2500 | 8.61 | 8.78 | ||

| 100 | 329 | 34 | 686 | 70 | 466 | 48 | 1440 | 147 | |||||||

| 160 | 370 | 38 | 823 | 84 | 590 | 60 | 1715 | 175 | |||||||

| Note:Moment of inertia I=1/4GD² | |||||||||||||||

| Model | Ratio | Rated torque of input speed 2000r/min | Max. torque of starting to stop | Max. torque of average load | Instant Max.torque | Max.input speed r/min | Average input speed r/min | Moment of inertia | |||||||

| Nm | kgfm | Nm | kgfm | Nm | kgfm | Nm | kgfm | Grease lubrication | Grease lubrication | I X10-4kgm² | J X10-5kgfms² | ||||

| 14 | 50 | 3.7 | 0.38 | 12 | 1.2 | 4.8 | 0.49 | 24 | 2.4 | 8500 | 3500 | 0.021 | 0.021 | ||

| 100 | 5.4 | 0.55 | 19 | 1.9 | 7.7 | 0.79 | 35 | 3.6 | |||||||

| 17 | 50 | 11 | 1.1 | 23 | 2.3 | 18 | 1.9 | 48 | 4.9 | 7300 | 3500 | 0.054 | 0.055 | ||

| 100 | 16 | 1.6 | 37 | 3.8 | 27 | 2.8 | 71 | 7.2 | |||||||

| 20 | 50 | 17 | 1.7 | 39 | 4.0 | 24 | 2.4 | 69 | 7.0 | 6500 | 3500 | 0.09 | 0.092 | ||

| 100 | 28 | 2.9 | 57 | 5.8 | 34 | 3.5 | 95 | 9.7 | |||||||

| 160 | 28 | 2.9 | 64 | 6.5 | 34 | 3.5 | 95 | 9.7 | |||||||

| 25 | 50 | 27 | 2.8 | 69 | 7.0 | 38 | 3.9 | 127 | 13 | 5600 | 3500 | 0.282 | 0.288 | ||

| 100 | 47 | 4.8 | 110 | 11 | 75 | 7.6 | 184 | 19 | |||||||

| 160 | 47 | 4.8 | 123 | 13 | 75 | 7.6 | 204 | 21 | |||||||

| 32 | 50 | 53 | 5.4 | 151 | 15 | 75 | 7.6 | 268 | 27 | 4800 | 3500 | 1.09 | 1.11 | ||

| 100 | 96 | 10 | 233 | 24 | 151 | 15 | 420 | 43 | |||||||

| 160 | 96 | 10 | 261 | 27 | 151 | 15 | 445 | 45 | |||||||

| 40 | 50 | 96 | 10 | 281 | 29 | 137 | 14 | 480 | 49 | 4000 | 3000 | 2.85 | 2.91 | ||

| 100 | 185 | 19 | 398 | 41 | 260 | 27 | 700 | 71 | |||||||

| 160 | 206 | 21 | 453 | 46 | 316 | 32 | 765 | 78 | |||||||

| Note:Moment of inertia I=1/4GD² | |||||||||||||||

Features

(1)Compact and precise design

(2)Hollow structure

(3)High static moment capacity

(4)Improving load capacity of output side bearing

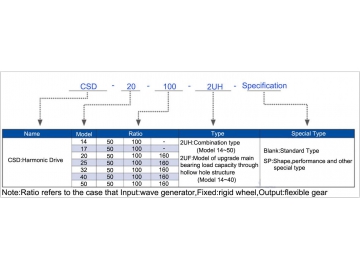

Indicated of model numbers

Download

Related products

Send Message

Most Recent

More

Other Products

Videos