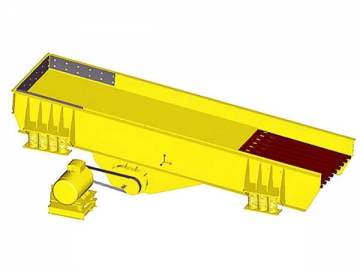

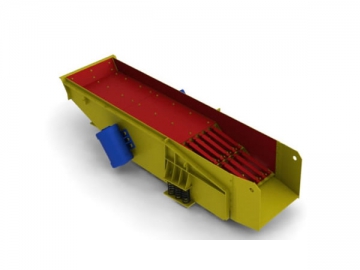

Vibratory Feeder (with Two Eccentric Shafts)

Product Brief Introduction

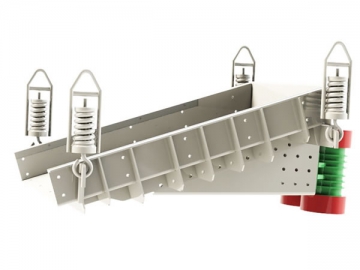

The design of the ZWS series biaxial vibratory feeder primarily consists of a vibrating frame, spring, motorized vibrating device, and an electrical motor.

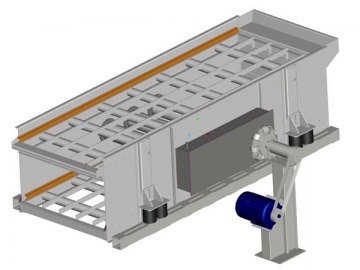

The biaxial vibratory feeder is made up of two eccentric shafts meshed with a toothed wheel. Each shaft of the vibrating feeder is driven by an electrical motor so as to produce a continuous vibrating effect and force materials to slide down the trough. When the materials get through the sieve strips on the tank, smaller materials will fall through the sieve gap.

Main Features of the Vibratory Feeder

- ABB motor

- Reduction box

- Vibration motor

- Vibration exciter

1. The feeding machine has two eccentric shafts that are driven by electrical motor to reach continuous and stable feeding.

2. Sieve strips on the tank make it possible to screen out materials that are larger than desired.

3. A wear-resistant liner can be applied on chute bottom.

4. Sealed body structure of the feeding system is to promote operator health.

5. Excellent adaptability, the temperature, moisture and the environment have little to no effect on it.

6. The vibratory feeder features low operating cost thanks to ease of use and maintenance.

7. The steel support spring can handle large dynamic loads.

Main Technical Parameters of the Vibratory Feeder

| Model | Max. feeding size(mm) | Process capacity (t/h) | Motor power (kW) | Installation inclination angle | Weight (kg) |

| 700 | 100-700 | 30 | 8° -12° | 9000 | |

| 800 | 100-700 | 30 | 8° -12° | 10000 | |

| 900 | 200-1000 | 30 | 8° -12° | 11000 | |

| 1000 | 300-1200 | 45 | 8° -12° | 16000 |