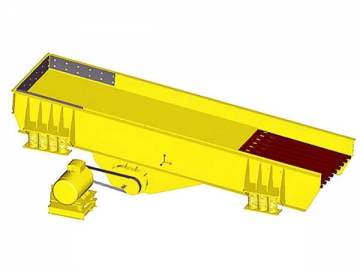

Linear Vibratory Feeder

Product Brief Introduction

The GZG linear vibratory feeder can supply large amounts of granular materials from storage silos in a uniform and continuous manner to the receiving device in materials crushing processes. Linear vibratory feeders guide materials into crushing equipment and can perform coarse screening of rough materials in its production line. This feeding equipment is widely used in the for rock crushing and screening for metallurgy, mining, mineral processing, building materials, and chemical industries.

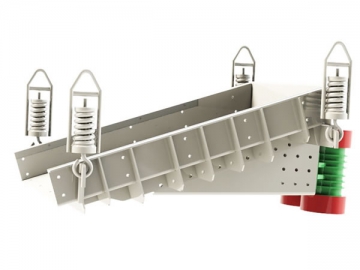

We can offer two styles of linear vibratory feeders according to the vibrating table design. One comes with flat plate style vibrating table, and the other comes with screening grilles. The latter supports feeding material size up to 700mm, and is driven by 2 sets of 9kw motors to offer maximum feeding capacity of 680t/h.

Main Features of the Linear Vibratory Feeder

- Damping spring

- Vibration motor

- Screening grilles

1. The vibrating feeder is easy to install and maintain due to its compact size and relative light weight.

2. Limited overall height for operation in restricted space is suitable for even the most demanding sites.

3. Reliable and continuous feeding performance with flexible application is an outstanding advantage of the GZG linear vibratory feeder.

4. Low noise and power consumption.

5. The feeding machine is driven by eccentric block drives for easy feeding adjustments.

6. A Closed frame structure can prevent dust pollution, which is good for both environmental factors and the health of the operator(s).

7. High tonnage, less downtime can realize maximum cost-efficiency.

Main Technical Parameters

Linear Vibratory Feeder with Flat Plate Style Vibrating Table

| Model | Maximum feeding size (mm) | Process capacity (t/h) | Motor power (kw) | Installation inclination angle | Weight (Kg) |

| 350 | 260 | 3.2×2 | 8°-12° | 3895 | |

| 500 | 350 | 5.5×2 | 8°-12° | 5170 | |

| 700 | 580 | 9×2 | 8°-12° | 7520 |

| Model | Maximum feeding size (mm) | Process capacity (t/h) | Motor power (kw) | Installation inclination angle | Weight (Kg) |

| 350 | 320 | 3.2×2 | 8°-12° | 4995 | |

| 500 | 450 | 5.2×2 | 8°-12° | 6585 | |

| 700 | 680 | 9×2 | 8°-12° | 8740 |