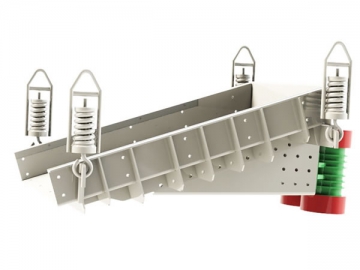

Linear Vibrating Screen

Available in 7 models, the linear vibrating screen can be used to screen materials with maximum size of 200mm. Its maximum screening capacity is up to 350t/h. This line of the screening equipment is driven by dual vibration motors.

Applications of the Linear Vibrating Screen

The linear motion vibratory screen can be used in many materials separation applications, such as mining, metallurgy, quarrying, building, and chemical industries for the separating of bulk materials such as stone aggregates, different kinds of sand, carbon, and other materials.

Mines: abrasives. glass, sand, potash, roofing granules, clay, petroleum coke, proppant beads, urea, bentonite, etc.

Chemical: fertilizer, ammonium sulfate, calcium hypochlorite, etc.

Plastic: commodity pellets, engineered pellets, PVC resin, etc.

Recycling: ground auto tires, ground PET bottles, ground glass bottles, recycled gypsum, etc.

Miscellaneous: metal powder, steel shot, wood flour, fly ash, etc.

Main Features and Benefits of the Linear Vibrating Screen

- Asynchronous motor

- Rubber spring

1. Performance

The modular design of the linear motion vibrating screen features a compact structure that makes it easy to install and maintain.

Powerful excitation source facilitates high capacity screening.

Customization is available.

2. Price

O.E.M. factory price is available.

Highly cost effective vibrating separator due to its efficient vibration motor.

The IP54 protection rank, F level insulation can protect the motor and reduce downtime, which minimizes maintenance costs.

3. Green

The sealing structure of the linear vibrating screen can be customized to prevent dust pollution.

Low noise output.

Main Technical Parameters of the Linear Vibrating Screen

| Model | screen area (m2) | Granularity (mm) | Capacity (TPH) | Frequency (r/min) | Double Amplitude (mm) | Motor power (kw) | Weight (kg) |

| 1.76 | ≤100 | 15-40 | 960 | 4-8 | 2*1.5 | 1500 | |

| 2.20 | ≤100 | 20-50 | 960 | 4-8 | 2*1.5 | 1950 | |

| 3.84 | ≤100 | 30-80 | 960 | 4-8 | 1*3.2 | 3150 | |

| 5.18 | ≤150 | 35-100 | 960 | 4-8 | 2*3.7 | 4200 | |

| 8.10 | ≤200 | 50-200 | 960 | 4-8 | 2*5.5 | 6300 | |

| 9.60 | ≤200 | 70-230 | 960 | 4-8 | 2*7.5 | 8350 | |

| 14.40 | ≤200 | 100-350 | 960 | 4-8 | 2*9 | 9700 |