Window Patcher, Double Lane Window Patching Machine CH-1100

The CH-1100 series window patcher is a double-lane machine that delivers a maximum production speed of 60,000 paper blanks per hour.

This dual lane window patcher makes quick work of tissue boxes, cosmetic boxes, gift boxes, arts and craft boxes, and other cardboard boxes with window patching. It can run two production lines simultaneously and the operator can decide to use single-lane production mode or double-lane production mode depending on the size of the cardboard sheets.

Equipped with a PLC (Programmable Logic Controller) system, the CH-1100 allows the operator to input the parameters on the touch screen to adjust the gluing and filming position without shutting down the machine.

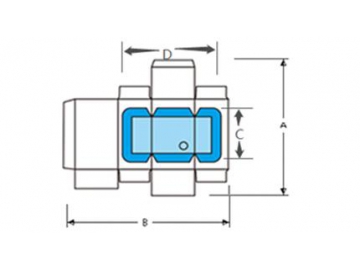

| Blank | Single Lane Operation | Double Lane Operation |

| Length A | 100 - 800 mm | 100 - 800 mm |

| Width B | 100 - 1000 mm | 100 - 480 mm |

| Length of Window C | 40 - 560 mm | 40 - 560 mm |

| Width of Window D | 30 - 940 mm | 30 - 430 mm |

| Carton Corrugated | 200g/㎡-600g/㎡ Up to 5 mm thickness | |

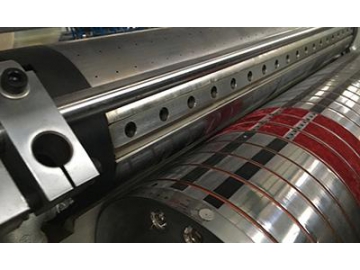

| Film thickness | 0.1 mm-0.45 mm | |

| Suitable Film Materials | PVC, PET, PP, Acetate, Compostable plastic film, RPET, APET | |

| Total Power | 10KW | |

| Machine Weight | 3000KG | |

| Machine Size | 6.5*3*1.6 (m) | |

| Output (Depend on the Blank Length) | Up to 60,000 sheets/hour | |

- Window with straight line perforation

- Window with intermittent slit

- Window with shaped perforation

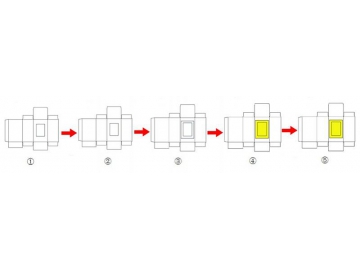

① Carton blank feeding ② Positioning ③ Gluing ④ Filming ⑤ Delivery

- Dual lane window patcher has higher production efficiency due to two lanes operation. Servo motor driven feeding system will delay carton blank feeding automatically if the previous is not in the right position in case of cardboards friction or belt wear.

- Feeding length can be easily adjusted via a button according to the computer-aided settings.

- This window patcher is equipped with an integrated cleaning system including a movable scraper, allowing for easy and fast cleaning within 2 minutes.

- Glue roller is made of 304 stainless steel for better corrosion and wear resistance.

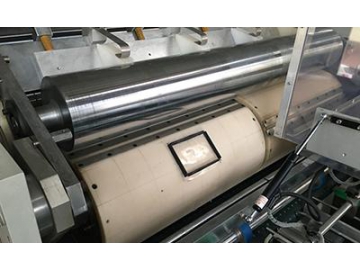

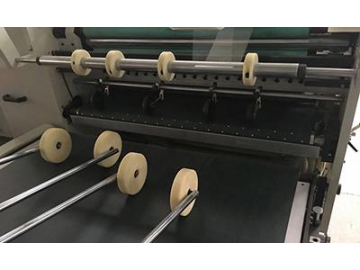

- Film is automatically cut and then added onto carton blanks using a suction cylinder. The roller surface is polished to prevent film from scratch.

- The rotary profile knife unit can be optionally equipped for tissue boxes production.

- Easy adjustment for positioning and film added onto the carton blanks without stopping the cardboard window patcher using a suction cylinder.

- The carton blanks will be transferred onto the conveyor belt in overlapped form.