Window Patcher with Hot Creasing Device CH-650

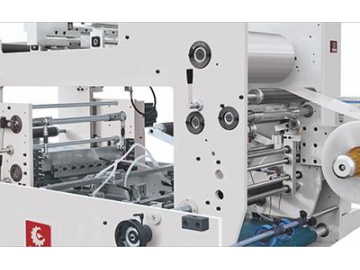

With die-cutting and line creasing for different plastic films, a maximum window patching speed is up to 8,000 paper sheets per hour, 8 KW machine power and the margin of error of the line creasing is no more than 0.5 mm. The CH-650 Series Window patcher can complete paper box window patching with efficiency and ease.

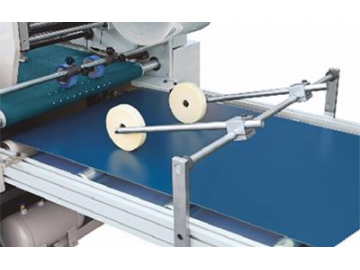

One of the most significant devices of this window patching machine is the die-cutting and line creasing device, which can crease lines on the film via heating, and it can also heat the film for embossing with molds, filming or other processes.

The operator can adjust the front and rear position of paper sheets via touch screen or mechanical adjustment mechanisms, and the operator can input the technical parameters on the touch screen to adjust the film position. Besides, the operator can adjust the gluing position according to the film position without shutting down the machine. This means that our window patching machines deliver high accuracy and precision with excellent results.

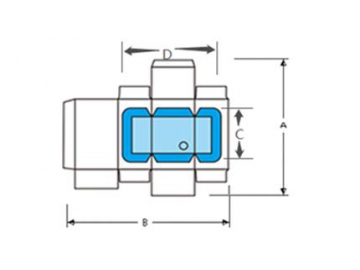

| Blank | Single Lane Operation |

| Length A Width B Length of window C Width of window D | 80mm-600mm 80mm-650mm 40mm-300mm 40mm-300mm |

| Carton Weight | |

| Carton Corrugated | 200g/m2-600g/m2, Up to 5 mm thickness |

| Film | |

| Film thickness | 0.1mm-0.45mm |

| Suitable Film Materials | PVC, PET, PP, Acetate, Pla compostable film, RPET, APET |

| Total Power | 8KW |

| Machine Weight | 3000kg |

| Machine Size | 6.8×2×1.8(m) |

| Output | 4000-8000 sheets/hour |

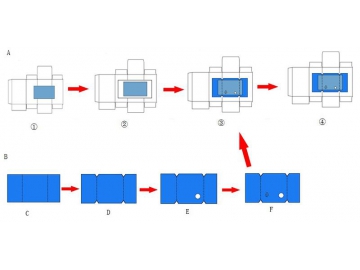

A Blank: ① Carton blank feeding ② Filming ③ Delivery

B: film; C: creasing; D: die cutting; E: perforation; F: embossing

- The belt conveyor is driven by servo motor, ensuring the intermittent feeding speed between carton blanks can be adjusted via a operator interface panel according to the blank length.

- The window patcher features continuous feeding.

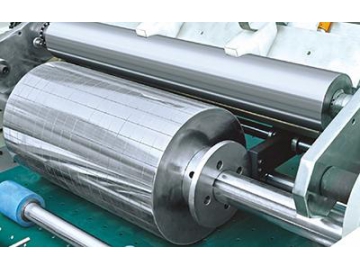

- This window patcher with hot creasing device is equipped with a 304 stainless steel cylinder with good corrosion resistance for distributing glue. The cylinder is easy for cleaning since glue does not stick on it.

- A blade is mounted on the glue roller to adjust glue thickness and width and to eliminate excess glue on the roller to prevent from dripping off, allowing for easy operation and glue saving.

- Glue roller with scale allows for easy and accurate installation.

- The glue roller will lift off automatically without carton boards feeding.

- This window patcher is equipped with pneumatic hot creasing device and die-cutter to perform die-cutting or creasing on carton blanks. The depth of creasing line could be adjusted at your desire and cutting wastes are batch collected.

- The film feeding speed is adjusted by a servo motor; film length can be adjusted without stopping the window patcher.

- The window patching equipment features a positioning device during the process of window film added on the blank, allowing for maximum deviation of 0.5mm.

- This window patcher comes with a memory function, so you can either save or retrieve data via a touch panel.

- The carton blanks will be transferred onto the conveyor belt in overlapped form.