Window Patcher, Single Lane Window Patching Machine TC-1100

Our TC-1100 series window patching machine features single-lane operation and operates with a maximum production speed of up to 20,000 paper blanks per hour. The machine can produce windows as wide as 300mm and with a maximum length of 500mm. The window patcher is ideal for producing tissue boxes, cosmetic boxes, gift boxes, food boxes, and other cardboard boxes for window patching.

The TC-1100 window patching machine is utilized for cardboard sheets that are 200g-600g in weight and 5mm in thickness for positioning, gluing, filming, and delivering processes. The window patching machine has a mono-suction belt which ensures the operator can feed paper blanks continuously, sharply increasing the window patching efficiency.

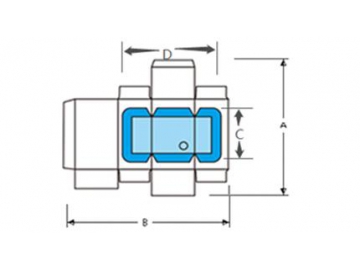

| Blank | Single Lane Operation |

| Length A Width B Length of window C Width of window D | 80mm-650mm 80mm-970mm 40mm-500mm 40mm-300mm |

| Carton Weight | |

| Carton Corrugated | 200g/m2-600g/m2, Up to 5 mm thickness |

| Film | |

| Film thickness | 0.03-0.25mm |

| Suitable Film Materials | PVC, PET, PP, Acetate, Pla compostable film, RPET, APET |

| Total Power | 8.5KW |

| Machine Weight | 2500kg |

| Machine Size | 5.5*2.2*1.8(m) |

| Output | 6000-20000 (sheets/hour) |

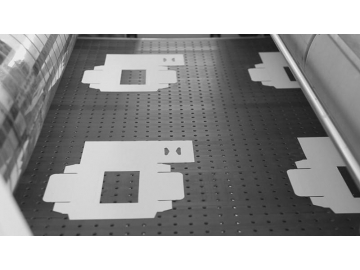

- Window with straight line perforation

- Window with intermittent slit

- Window with shaped perforation

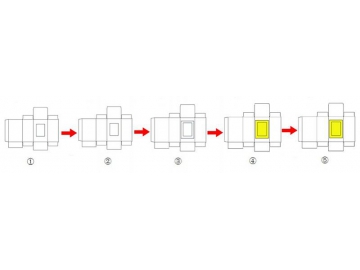

① Carton blank feeding ② Positioning ③ Gluing ④ Filming ⑤ Delivery

When carton blank is fed into window patcher, pin positioning unit is used to ensure precise alignment of carton blank. Then gluing is carried out using a glue roller to make sure carton blank is evenly glued. After that, film in a specific length is placed using a suction cylinder, and then patched on the carton blank. Finally, the reels outfeed the window patched cartons.

During machine operation, adjustment can be carried out without shutting down the machine, thus saving time.

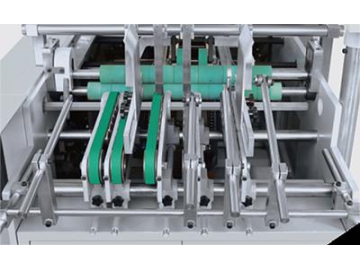

- The servo motor driven window patcher is equipped with belt conveyor using Nitta conveyor belt from Japan to deliver cardboards with stable and high speed non-stop feeding.

- The belt conveyor is driven by servo motor, ensuring the intermittent feeding speed between carton blanks can be adjusted via a operator interface panel according to the cardboard length.

- The rack and pinion belt tensioning device allows for stable and smooth carton blank feeding.

- Carton blanks feeding with stable and high speed.

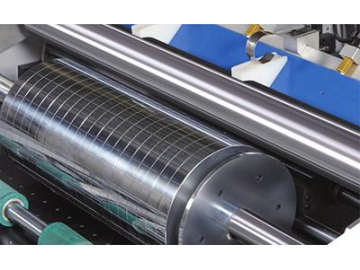

- Gluing device is able to pull out from the window patching machine for cleanup. The glue roller with scale allows for easy and accurate installation.

- Gluing positions can be adjusted without stopping the cardboard window patcher.

- The glue roller will lift off automatically when stop feeding carton blanks, avoiding leaving glue on the conveyor belt.

- This window patcher is equipped with movable scraper system to eliminate excess glue on rollers to prevent dripping off.

- Film is automatically cut and added onto carton blanks with a suction cylinder.

- The rotary profile knife unit can be optionally equipped for tissue boxes production.

- Easy adjustment for film positioning and film added the carton blanks without stopping the cardboard window patcher using suction cylinder.

- The carton blanks will be transferred onto the conveyor belt in overlapped form.

- Servo motor driven belt conveyor allows for better adjustment on conveying speed according to different carton blanks.

- The length of delivery table can be customized based on your requirements.