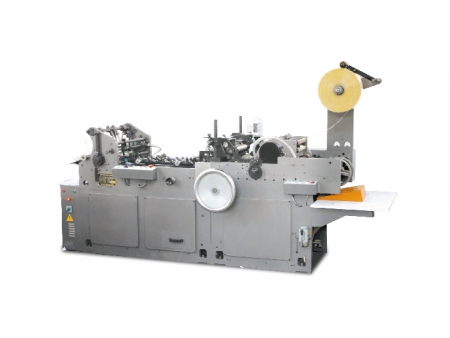

KTM410 Automatic Window-Patching Machine

The KTM410 automatic window-patching machine is used to open window and patch the film on a variety of international and domestic standard envelopes and flat bags. This model can also be attached to different machines, including the BW292 Model, POCKET124 Model, or POCKET135 Model to produce different window envelopes. The KTM410 is known for its high efficiency, stable functions, easy operation, quick adjustments and space saving structure, making it ideal for mass production jobs.

Major Structural Features

Using a suction method at the lower portion of the machine, blank paper that is laid on the feed plate is fed into machine. This method allows the pile of blanks to be replenished while the machine is operating, and no extra downtime. The paper orientation unit works with both convenience and accuracy while the lateral and longitudinal folding units help add to the overall quality of the products. Rotary glue applying unit meets the requirements of glue tracks of any shape, and assisted by the suction cylinder, the folding unit works in a stable manner. A graduated disk accurately and directly shows the adjustment volume, while the collection unit is equipped with an electronic counting and batching system.

For product changes, Without notice.

| Technical Info | | |

| Max.Paper Blank Size (mm) | 410×350 | 410×350 |

| Window Length (mm) | 35-140 | 35-140 |

| Window Width (mm) | 15-120 | 15-120 |

| Window Die Cutting | in | no |

| Max. Patching size (mm) | 140×160 | 140×160 |

| Min. Patching size (mm) | 35×55 | 35×55 |

| Paper Weights Ca (gsm) | 80-120 | 80-120 |

| Total Power (kW) | 4.5 | 4.1 |

| Max. Speed (pcs/h) | 11000 | 12000 |

| Machine Weight (kg) | 3000 | 2300 |

| Machine Size (L×W×H)(m) | 3500×1090×1720 | 3200×1090×1720 |