AT-CR Precision Steering Speed Reducer

AT-CR precision steering speed reducer has extensive application in printing machine, belt conveyor, gantry robot, automatic case packer, vertical or transverse pillow-type packing machine, dispenser robot, loading robot and other machineries. Besides, it is perfectly suited to multi-axis linkage occasions including TFT-LCD lifting machinery, various kinds of lifting machinery and horizontal linkage machineries.

| Model No. | Stage | Ratio(i) | AAW070AS | AAW080AS AT080AS ATM080AS AAW080AS-HR | AAW110AS AT110AS ATM110AS AAW110AS-HR | AAW135AS AT135AS ATM135AS AAW135AS-HR | AAW135BS | AAW165AS AT165AS ATM165AS | AAW165BS ATM165BS AAW165BS-HR | AAW200AS | AAW200BS AT200BS ATM200BS AAW200BS-HR | AAW320AS AAW320AS-HR | AAW320BS |

| Rated Output Torque(Nm) | L1 | 2, 3, 5, 10 | 30 | 80 | 250 | 450 | * | 800 | * | 2000 | * | 3500 | * |

| 6 | * | 80 | 200 | 400 | 280 | 700 | 600 | 1500 | 1000 | 3500 | 2000 | ||

| 8 | * | 85 | 250 | 450 | 320 | 800 | 660 | 1850 | 1100 | 4000 | 2300 | ||

| 10 | * | 85 | 250 | 450 | 320 | 800 | 660 | 1850 | 1100 | 4000 | 2300 | ||

| 12 | * | 80 | 225 | 435 | 320 | 750 | 660 | 1850 | 1100 | * | 2300 | ||

| 14 | * | 80 | 215 | 425 | 280 | 750 | 600 | 1750 | 1000 | 3500 | 2200 | ||

| 16 | * | 80 | 210 | 415 | 270 | 700 | 600 | 1700 | 1000 | * | * | ||

| 20 | 30 | 70 | 200 | 400 | 240 | 700 | 460 | 1650 | 900 | 3000 | 1900 | ||

| L2 | 30 | 30 | 80 | 200 | 400 | 280 | 700 | 600 | 1500 | 1000 | 3500 | 2000 | |

| 32 | * | 85 | 250 | 450 | 320 | 800 | 660 | 1850 | 1100 | 4000 | 2300 | ||

| 40 | 30 | 85 | 250 | 450 | 320 | 800 | 660 | 1850 | 1100 | 4000 | 2300 | ||

| 50 | 30 | 85 | 250 | 450 | 320 | 800 | 660 | 1850 | 1100 | 4000 | 2300 | ||

| 56 | * | 85 | 250 | 450 | 320 | 800 | 660 | 1850 | 1100 | 3500 | 2300 | ||

| 60 | * | 80 | 200 | 400 | 280 | 700 | 600 | 1500 | 1000 | 3500 | 2000 | ||

| 70 | 30 | 85 | 250 | 450 | 320 | 800 | 660 | 1850 | 1100 | 3500 | 2200 | ||

| 80 | * | 85 | 250 | 450 | 320 | 800 | 660 | 1850 | 1100 | 3500 | 2300 | ||

| 100 | 30 | 85 | 250 | 450 | 320 | 800 | 660 | 1850 | 1100 | 3500 | 2300 | ||

| 120 | * | 80 | 225 | 435 | 290 | 750 | 630 | 1750 | 1050 | * | 2200 | ||

| 140 | * | 80 | 215 | 425 | 280 | 750 | 630 | 1750 | 1000 | 3200 | 2100 | ||

| 160 | * | 80 | 210 | 415 | 270 | 700 | 600 | 1700 | 950 | * | * | ||

| 200 | 30 | 70 | 200 | 400 | 240 | 700 | 460 | 1700 | 900 | 3000 | 1900 | ||

| Max. Output Torque(Nm) | L1,L2 | 3~100 | 2.5 Times of Normal Output Torque | ||||||||||

| Input Speed(rpm) | L1,L2 | 3~100 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 |

| Standard Backlash (arc-min) | L1 | 3~10 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 |

| L2 | 12~100 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | |

| Precision Backlash B2 (arc-min) | L1 | 3~10 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

| L2 | 12~100 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | |

| Precision Backlash B1 (arc-min) | L1 | 3~10 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 |

| L2 | 12~100 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | |

| Precision Backlash B0 (arc-min) | L1 | 3~10 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| L2 | 12~100 | ≤2 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | |

| Max. Radial Force(N) | L1,L2 | 3~100 | 2800 | 3900 | 5500 | 9800 | 9800 | 16500 | 16500 | 24100 | 24100 | 35600 | 32600 |

| Max. Axial Force(N) | L1,L2 | 3~100 | 2800 | 3900 | 5500 | 9800 | 9800 | 16500 | 16500 | 24100 | 24100 | 32600 | 32600 |

| Efficiency(%) | L1 | 3~10 | 90% | ||||||||||

| L2 | 12~100 | 85% | |||||||||||

| Weight(kg) | L1 | 3~10 | 2.5 | 7.8 | 4.3 | 20.8 | 15.5 | 35.5 | 28.5 | 55 | 40.5 | 300 | 270 |

| L2 | 12~100 | 3.8 | 9.2 | 6.3 | 24.3 | 18.2 | 40.5 | 31.2 | 65.5 | 48.5 | 330 | 290 | |

| Operating Temp. (℃) | L1,L2 | 3~100 | -10℃~+80℃ | ||||||||||

| Lubrication | L1,L2 | 3~100 | COMPLEX HV2 | ||||||||||

| Mounting Position | L1,L2 | 3~100 | Any Direction | ||||||||||

| Noise Level(db) | L1,L2 | 3~100 | ≤65 | ≤68 | ≤68 | ≤68 | ≤68 | ≤70 | ≤70 | ≤72 | ≤72 | ≤72 | ≤72 |

1. High strength: use high precision spiral bevel gear, made of nickel-chrome alloy steel(SCM415 HRC60)

2. High efficiency: combination of effective planetary mechanism and precision spiral bevel gear

3. High rigidity: the gear box has excellent rigid structure, supported by double conical bearings, especially applicable for the occasions where output load changes greatly.

4. Diversity: adopt diversified output shafts

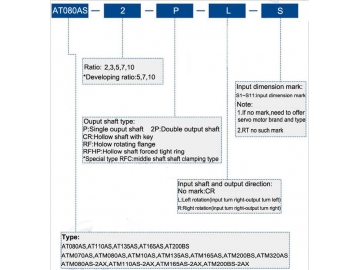

5. Reduction ratio: 1-stage: 3-10; 2-stage: 12-100

6. Small in volume and space-saving: frame size: 55MM-220MM

7. Easy installation: it can be installed on one of its five surfaces.

8. Output torque: 15Nm-1600Nm, Modulus of spiral bevel gear: M1.0-M6.0

9. Suitable capacity: 50W-15KW