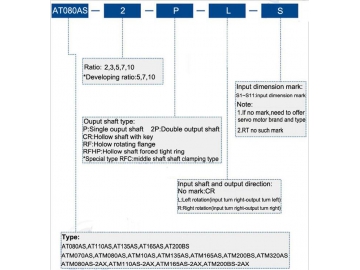

AT-2P Precision Steering Speed Reducer

AT-2P precision steering speed reducer can be widely applied to printing press, belt conveyor, gantry robot, automatic box filling machine, packing machine(vertical or transverse pillow type), dispenser robot, loading robot and other mechanical equipment. In addition, it is very suitable for multi-axis linkage occasions including TFT-LCD lifting machinery, various kinds of lifting machinery as well as horizontal linkage machineries.

| Model No. | Stage | Ratio(i) | AAW070AS | AAW080AS AT080AS ATM080AS AAW080AS-HR | AAW110AS AT110AS ATM110AS AAW110AS-HR | AAW135AS AT135AS ATM135AS AAW135AS-HR | AAW135BS | AAW165AS AT165AS ATM165AS | AAW165BS ATM165BS AAW165BS-HR | AAW200AS | AAW200BS AT200BS ATM200BS AAW200BS-HR | AAW320AS AAW320AS-HR | AAW320BS |

| Rated Output Torque(Nm) | L1 | 2, 3, 5, 10 | 30 | 80 | 250 | 450 | * | 800 | * | 2000 | * | 3500 | * |

| 6 | * | 80 | 200 | 400 | 280 | 700 | 600 | 1500 | 1000 | 3500 | 2000 | ||

| 8 | * | 85 | 250 | 450 | 320 | 800 | 660 | 1850 | 1100 | 4000 | 2300 | ||

| 10 | * | 85 | 250 | 450 | 320 | 800 | 660 | 1850 | 1100 | 4000 | 2300 | ||

| 12 | * | 80 | 225 | 435 | 320 | 750 | 660 | 1850 | 1100 | * | 2300 | ||

| 14 | * | 80 | 215 | 425 | 280 | 750 | 600 | 1750 | 1000 | 3500 | 2200 | ||

| 16 | * | 80 | 210 | 415 | 270 | 700 | 600 | 1700 | 1000 | * | * | ||

| 20 | 30 | 70 | 200 | 400 | 240 | 700 | 460 | 1650 | 900 | 3000 | 1900 | ||

| L2 | 30 | 30 | 80 | 200 | 400 | 280 | 700 | 600 | 1500 | 1000 | 3500 | 2000 | |

| 32 | * | 85 | 250 | 450 | 320 | 800 | 660 | 1850 | 1100 | 4000 | 2300 | ||

| 40 | 30 | 85 | 250 | 450 | 320 | 800 | 660 | 1850 | 1100 | 4000 | 2300 | ||

| 50 | 30 | 85 | 250 | 450 | 320 | 800 | 660 | 1850 | 1100 | 4000 | 2300 | ||

| 56 | * | 85 | 250 | 450 | 320 | 800 | 660 | 1850 | 1100 | 3500 | 2300 | ||

| 60 | * | 80 | 200 | 400 | 280 | 700 | 600 | 1500 | 1000 | 3500 | 2000 | ||

| 70 | 30 | 85 | 250 | 450 | 320 | 800 | 660 | 1850 | 1100 | 3500 | 2200 | ||

| 80 | * | 85 | 250 | 450 | 320 | 800 | 660 | 1850 | 1100 | 3500 | 2300 | ||

| 100 | 30 | 85 | 250 | 450 | 320 | 800 | 660 | 1850 | 1100 | 3500 | 2300 | ||

| 120 | * | 80 | 225 | 435 | 290 | 750 | 630 | 1750 | 1050 | * | 2200 | ||

| 140 | * | 80 | 215 | 425 | 280 | 750 | 630 | 1750 | 1000 | 3200 | 2100 | ||

| 160 | * | 80 | 210 | 415 | 270 | 700 | 600 | 1700 | 950 | * | * | ||

| 200 | 30 | 70 | 200 | 400 | 240 | 700 | 460 | 1700 | 900 | 3000 | 1900 | ||

| Max. Output Torque(Nm) | L1,L2 | 3~100 | 2.5 Times of Normal Output Torque | ||||||||||

| Input Speed(rpm) | L1,L2 | 3~100 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 |

| Standard Backlash (arc-min) | L1 | 3~10 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 |

| L2 | 12~100 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | |

| Precision Backlash B2 (arc-min) | L1 | 3~10 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

| L2 | 12~100 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | |

| Precision Backlash B1 (arc-min) | L1 | 3~10 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 |

| L2 | 12~100 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | |

| Precision Backlash B0 (arc-min) | L1 | 3~10 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| L2 | 12~100 | ≤2 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | |

| Max. Radial Force(N) | L1,L2 | 3~100 | 2800 | 3900 | 5500 | 9800 | 9800 | 16500 | 16500 | 24100 | 24100 | 35600 | 32600 |

| Max. Axial Force(N) | L1,L2 | 3~100 | 2800 | 3900 | 5500 | 9800 | 9800 | 16500 | 16500 | 24100 | 24100 | 32600 | 32600 |

| Efficiency(%) | L1 | 3~10 | 90% | ||||||||||

| L2 | 12~100 | 85% | |||||||||||

| Weight(kg) | L1 | 3~10 | 2.5 | 7.8 | 4.3 | 20.8 | 15.5 | 35.5 | 28.5 | 55 | 40.5 | 300 | 270 |

| L2 | 12~100 | 3.8 | 9.2 | 6.3 | 24.3 | 18.2 | 40.5 | 31.2 | 65.5 | 48.5 | 330 | 290 | |

| Operating Temp. (℃) | L1,L2 | 3~100 | -10℃~+80℃ | ||||||||||

| Lubrication | L1,L2 | 3~100 | COMPLEX HV2 | ||||||||||

| Mounting Position | L1,L2 | 3~100 | Any Direction | ||||||||||

| Noise Level(db) | L1,L2 | 3~100 | ≤65 | ≤68 | ≤68 | ≤68 | ≤68 | ≤70 | ≤70 | ≤72 | ≤72 | ≤72 | ≤72 |

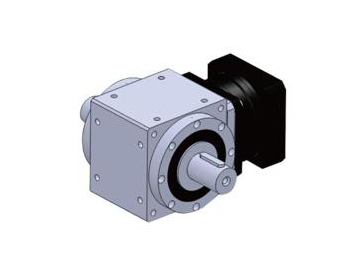

1. High strength: high precision spiral bevel gear, made of nickel-chrome alloy steel(SCM415 HRC60), is adopted

2. High efficiency: combine effective planetary mechanism and precision spiral bevel gear

3. High stiffness: with excellent rigid structure of the gear box, supported by double cone-shaped bearings, it is perfectly suitable for occasions where output load changes much.

4. Diversity: diversified output shafts are available

5. Reduction ratio: 1-stage: 3-10; 2-stage: 12-100

6. Small in volume and space-saving: frame size: 55MM-220MM

7. Easy installation: the installation on five surfaces of the gear box is available.

8. Output torque: 15Nm-1600Nm, Modulus of spiral bevel gear: M1.0-M6.0

9. Applicable capacity: 50W-15KW