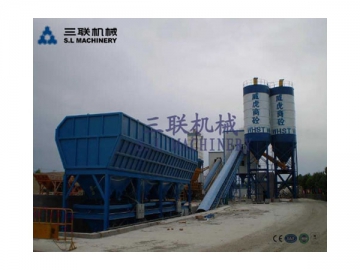

Concrete Mixing Plant (Modular Structure), HZS Series

Characteristics

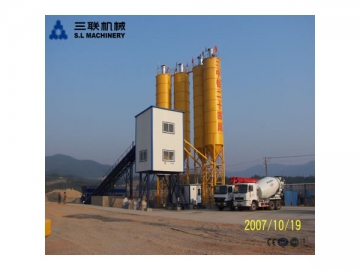

HZS series modular cement concrete mixing plants are new types of concrete mixing plants designed by S.L Construction Machinery adopting the worldwide advanced technologies and research achievements with many years of experiences in production of concrete mixing plants.

This series of mixing plants is suitable for large construction sites for roads, bridges, dams, airports and ports, as well as various construction sites with great demand on ready-mixed concrete.

Convenient jobsite-transfer and installation

HZS series concrete mixing plant features a modular structure. The batching machine, belt conveyor, mixing tower, screw conveyor and cement silo are all independent units. The mixing tower is made up of several independent modules. The plant is easy and speedy on assemble and disassemble, convenient for transportation, and has been provided with various plant arrangement to suit different jobsite demands.

Outstanding environmental protection performance

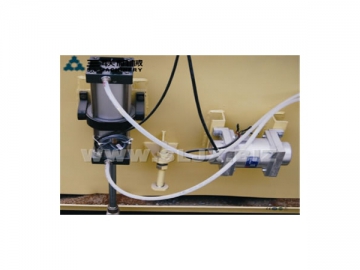

The feeding, weighing, mixing and discharging of all powder material run in closed situation, which greatly reduce negative effect of dust and noise to environment.

- Transition Bin

- Dust

- Aggregate Conveying

- Bunker Door Opening Device

The HZS60 modular concrete mixing plant is designed by Sanlian using the cutting-edge technologies and based on our rich experience in production of concrete machinery. Providing a production capacity of 60m3/h, this concrete batching system is widely used in road, bridge, dam, airport, port and other construction projects.

Characteristics of the Concrete Mixing Plant

Convenient Transfer between Jobsites and Easy Installation

The concrete plant features a modular structure. The batching machine, belt conveyor, mixing system, screw conveyor and cement silo in the batching plant are all independent units. They enable easy and fast assembly and disassembly, providing high convenience for transfer between jobsites. It provides a variety of layouts suit for different jobsites.

Outstanding Environment Protection Performance

Feeding, weighing, mixing and discharging of all powder materials run in a closed situation for dust prevention and noise reduction.

| Model | ||

| Mixer | Productivity (m3/h) | 60 |

| Type | JS1000 | |

| Power (kW) | 2×22 | |

| Output (m3) | 1 | |

| Aggregate Diameter (mm) | ≤80 | |

| Batching Hopper | Hopper Volume(m3) | 3x13 |

| Hopper Quantity | 3 | |

| Belt Conveyor Capacity (t/h) | 200 | |

| Weighing Scope and Accuracy | Aggregate (kg) | 4×1500±2% |

| Cement (kg) | 600±1% | |

| Fly-ash (kg) | 200±1% | |

| Water (kg) | 250±1% | |

| Admixture (kg) | 20±1% | |

| Total Power (kW) | 82 | |

| Discharge Height (m) | ≥3.8 | |

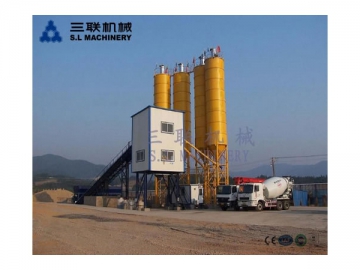

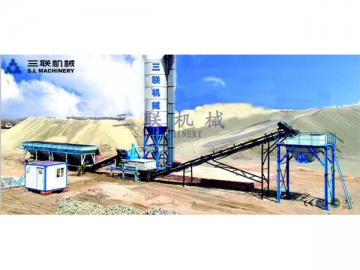

Designed and manufactured using the world leading technologies, combining Sanlian's years of experience in production of concrete plants, the HZS90 modular concrete mixing plant is an ideal choice for large construction sites where ready-mix concrete is in great demand. To be specific, the ready-mix concrete plant is great for road, bridge, dam, airport, port and other construction projects.

-

HZS90-1 -

HZS90-2

Characteristics of the Concrete Mixing Plant

Easy to Assemble, Disassemble and Transport

Due to modular structure, all equipment in the batch plant including batching machine, belt conveyor, concrete mixer, screw conveyor and cement silo are independent units, making the whole machinery easy to assemble, disassemble and transport. Therefore, it enables high convenience for transfer between jobsites. With a variety of layout options, the concrete plant is suitable for all kinds of jobsites.

Notably Eco-Friendly

Operations of all powder materials including screw feeding, weighing, mixing and discharging are reliably controlled for minimal dust emission and extremely low noise.

| Model | ||

| Mixer | Productivity (m3/h) | 90 |

| Type | JS1500 | |

| Power (kW) | 2×30 | |

| Output (m3) | 1.5 | |

| Aggregate Diameter (mm) | ≤100 | |

| Batching Hopper | Hopper Volume (m3) | 4 ×13 |

| Hopper Quantity | 4 | |

| Belt Conveyor Capacity (t/h) | 200 | |

| Weighing Scope and Accuracy | Aggregate (kg) | 4×2000±2% |

| Cement (kg) | 900±1% | |

| Fly-ash (kg) | 300±1% | |

| Water (kg) | 400±1% | |

| Admixture (kg) | 30±1% | |

| Total Power (kW) | 108 | |

| Discharge Height (m) | ≥3.8 | |

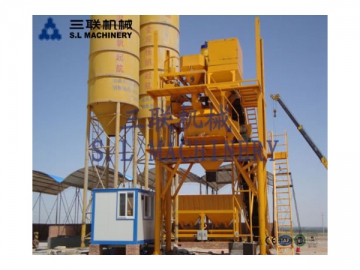

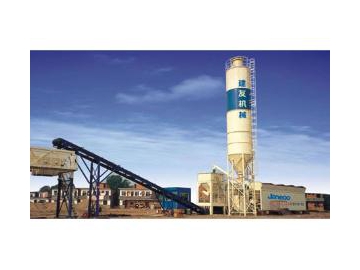

Find a concrete mixing plant used for large construction sites such as constructions of road, bridge, dam, airport, port, etc.? Our HZS120 concrete plant in modular design provides remarkable advantages for your applications.

-

HZS120-1 -

HZS120-2

First, this concrete solution is designed on the basis of cutting edge technologies and our rich experiences in the manufacture of concrete batching plants. It is a combination of high productivity, high efficiency, low dust emission and low noise.

In addition, modular structure enables the whole concrete mixing plant to be readily assembled and disassembled. Therefore, transfer between jobsites is not a hard problem. A diversity of layout solutions makes it ideal for various jobsites.

Technical Parameters of the Concrete Mixing Plant| Model | ||

| Mixer | Productivity (m3/h) | 120 |

| Type | JS2000 | |

| Power(kW) | 2×37 | |

| Output (m3) | 2 | |

| Aggregate Diameter (mm) | ≤120 | |

| Batching Hopper | Hopper Volume (m3) | 4x15 |

| Hopper Quantity | 4 | |

| Belt Conveyor Capacity (t/h) | 300 | |

| Weighing Scope and Accuracy | Aggregate (kg) | 4×2200±2% |

| Cement (kg) | 1200±1% | |

| Fly-ash (kg) | 400±1% | |

| Water (kg) | 500±1% | |

| Admixture (kg) | 30±1% | |

| Total Power (kW) | 127 | |

| Discharge Height (m) | ≥3.8 | |

The HZS180 modular concrete mixing plant is a preferred choice for large capacity concrete production needs. The production capacity of this concrete mixing system is up to 180m3/h. Designed using cutting edge technologies and combining our rich experiences in the manufacture of concrete equipment, the concrete plant provides a combination of high productivity, high efficiency, and remarkable environment protection. It is widely used in large construction projects including road, bridge, dam, airport and port constructions and others.

-

HZS180-1 -

HZS180-2

Characteristics of the Concrete Mixing Plant

Convenient Jobsite Transfer and Easy Installation

Modular structure makes sure that the batching machine, belt conveyor, mixing system, screw conveyor and cement silo in the batching plant are all independent units. They enable easy and fast assembly and disassembly, providing high convenience for transfer between jobsites. Additionally, various layout solutions make it suitable for different construction sites.

Environmental Protection

The concrete batching plant is featured by prominent environmental protection performance. Feeding, weighing, mixing and discharging of all powder materials run in a closed situation for dust prevention and noise reduction.

| Model | ||

| Mixer | Productivity (m3/h) | 180 |

| Type | JS3000 | |

| Power (kW) | 2×55 | |

| Output (m3) | 3 | |

| Aggregate Diameter (mm) | ≤150 | |

| Batching Hopper | Hopper Volume (m3) | 4x20 |

| Hopper Quantity | 4 | |

| Belt Conveyor Capacity (t/h) | 400 | |

| Weighing Scope and Accuracy | Aggregate (kg) | 4×3600±2% |

| Cement (kg) | 1800±1% | |

| Fly-ash (kg) | 600±1% | |

| Water (kg) | 800±1% | |

| Admixture (kg) | 50±1% | |

| Total Power (kW) | 178 | |

| Discharge Height (m) | ≥4 | |

Note:

1. The total power excludes the power of screw conveyor;

2. The quantity and volume of hopper can be designed as required;

3. All above specifications are subject to final products