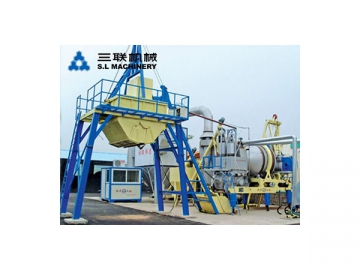

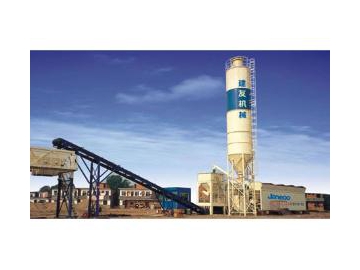

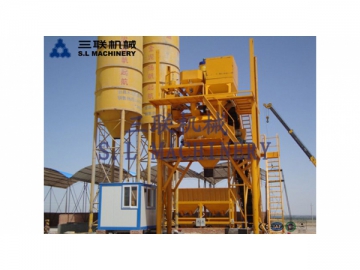

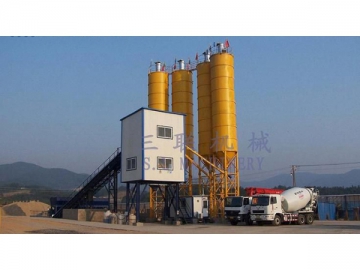

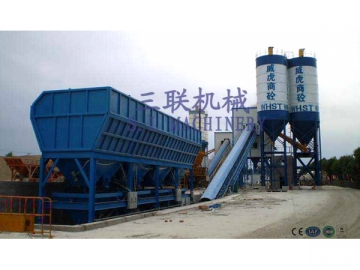

Concrete Mixing Plant (Tower Structure), HZS Series

The HZS series ready-mix concrete mixing plant of tower structure is developed based on the technology of internationally advanced concrete mixing machine. Taking the leading position in the industry, the concrete mixer employs key parts from famous suppliers home and abroad. The main mixing tower is composed of certain separate modules, enabling easy disassembly, rapid installation, and convenient transportation. What's more, the construction machinery is very popular because of the following features.

1. Easy maintenance and operation

2. Good stability

3. Environment protection

4. Accurate metering performance

5. Optimal mixing property

- Mixing System

- Control System

- Batching Hopper

- Discharge Outlet

- Powder Conveying and Measuring

- Ground-bin Type Aggregate Proportioning Station

Description

The HZS60 concrete mixing plant with tower structure is developed by Sanlian based on the state of the art concrete mixing technology in the world. Main components in this concrete batch plant are all from renowned suppliers both at home and abroad, ensuring high quality and reliability, and keeping the concrete equipment running at peak performance. The main batching plant is constructed from certain separate modules, enabling easy disassembly, rapid installation, and convenient transportation.

Features and Advantages of the Concrete Mixing Plant

1. Simple maintenance with low cost;

2. Easy and fast installation;

3. Exceptional stability and reliability in use;

4. Eco-friendly

| Model | ||

| Mixer | Productivity (m3/h) | 60 |

| Type | JS1000 | |

| Power (kW) | 2×22 | |

| Output (m3) | 1 | |

| Aggregate Diameter (mm) | ≤60 | |

| Batching Hopper | Hopper Volume (m3) | 13 |

| Hopper Quantity | 3 | |

| Belt Conveyor Capacity (t/h) | 300 | |

| Weighing Scope and Accuracy | Aggregate (kg) | 2400±2% |

| Cement (kg) | 600±1% | |

| Fly-ash (kg) | 200±1% | |

| Water (kg) | 250±1% | |

| Admixture (kg) | 1×30±1% | |

| Total Power (kW) | 92 | |

| Discharge Height (m) | ≥3.8 | |

Note:

1. The total power excludes the power of screw conveyor;

2. The quantity and volume of hopper can be designed as required;

3. All above specifications are subject to final products

With up to 90m2/h mixing capacity, our HZS90 concrete mixing plant is an international leading tower type concrete plant developed by absorption of cutting-edge mixing technology. Key parts of the concrete machinery come from the most reputable suppliers in the world, which provide the highest quality and cost efficiency. In today's construction industry, the concrete batching plant is highly welcomed by users due to its advantages of easy installation and maintenance, high stability and reliability in operation and great environmental performance.

Technical Parameters of the Concrete Mixing Plant| Model | ||

| Mixer | Productivity (m3/h) | 90 |

| Type | JS1500 | |

| Power (kW) | 2×30 | |

| Output (m3) | 1.5 | |

| Aggregate Diameter (mm) | ≤80 | |

| Batching Hopper | Hopper Volume (m3) | 15 |

| Hopper Quantity | 4 | |

| Belt Conveyor Capacity (t/h) | 450 | |

| Weighing Scope and Accuracy | Aggregate (kg) | 4×2000±2% |

| Cement (kg) | 900±1% | |

| Fly-ash (kg) | 300±1% | |

| Water (kg) | 400±1% | |

| Admixture (kg) | 2×30±1% | |

| Total Power (kW) | 120 | |

| Discharge Height (m) | ≥3.8 | |

Note:

1. The total power excludes the power of screw conveyor;

2. The quantity and volume of hopper can be designed as required;

3. All above specifications are subject to final products

The HZS120 concrete mixing plant is a preferred ready-mix plant designed with a tower structure. It is engineered and manufactured by Sanlian depending on the world's state of the art technologies. To meet customer's requirements for high performance concrete production, with high efficiency and minimum downtime, key parts of the stationary concrete plant are all from world renowned suppliers.

Advantages of the Concrete Mixing Plant Include:

1. Simple maintenance with low cost;

2. Easy and fast installation;

3. Exceptional stability and reliability in use;

4. Environmental protection

| Model | ||

| Mixer | Productivity (m3/h) | 120 |

| Type | JS2000 | |

| Power (kW) | 2×37 | |

| Output (m3) | 2 | |

| Aggregate Diameter (mm) | ≤120 | |

| Batching Hopper | Hopper Volume (m3) | 20 |

| Hopper Quantity | 4 | |

| Belt Conveyor Capacity (t/h) | 550 | |

| Weighing Scope and Accuracy | Aggregate (kg) | 4×2200±2% |

| Cement (kg) | 1200±1% | |

| Fly-ash (kg) | 400±1% | |

| Water (kg) | 500±1% | |

| Admixture (kg) | 2×50±1% | |

| Total Power (kW) | 140 | |

| Discharge Height (m) | ≥3.8 | |

Note:

1. The total power excludes the power of screw conveyor;

2. The quantity and volume of hopper can be designed as required;

3. All above specifications are subject to final products

Here's our HZS180 concrete mixing plant which provides up to 180m3/h mixing capacity and is ideal for large capacity concrete production needs. Designed on the basis of the state of the art concrete batching and mixing technologies in the world, and equipped with market leading parts of world famous brands, this stationary concrete batching plant is exactly worth of your investment.

In addition, the construction machinery will not disappoint you because of remarkable characteristics such as easy and cost effective maintenance, fast installation, excellent stability and reliability in use and environmental protection.

Technical Parameters of the Concrete Mixing Plant| Model | ||

| Mixer | Productivity (m3/h) | 180 |

| Type | JS3000 | |

| Power (kW) | 2×55 | |

| Output (m3) | 3 | |

| Aggregate Diameter (mm) | ≤150 | |

| Batching Hopper | Hopper Volume (m3) | 25 |

| Hopper Quantity | 4 | |

| Belt Conveyor Capacity (t/h) | 650 | |

| Weighing Scope and Accuracy | Aggregate (kg) | 4×3600±2% |

| Cement (kg) | 1800±1% | |

| Fly-ash (kg) | 600±1% | |

| Water (kg) | 800±1% | |

| Admixture (kg) | 2×50±1% | |

| Total Power (kW) | 190 | |

| Discharge Height (m) | ≥4 | |

Note:

1. The total power excludes the power of screw conveyor;

2. The quantity and volume of hopper can be designed as required;

3. All above specifications are subject to final products

| Model | ||||||

| Theoretical Productivity (m3/h) | 60 | 90 | 120 | 180 | 240 | |

| Mixer | Type | JS1000 | JS1500 | JS2000 | JS3000 | JS4000 |

| Power (kW) | 2×22 | 2×30 | 2×37 | 2×55 | 2×75 | |

| Output (m3) | 1 | 1.5 | 2 | 3 | 4 | |

| Aggregate Size (mm) | ≤60 | ≤80 | ≤120 | ≤150 | ≤150 | |

| Batching Hopper | Hopper Volume (m3) | 13 | 15 | 20 | 25 | 30 |

| Hopper Quantity | 3 | 4 | 4 | 4 | 4 | |

| Belt Conveyor Capacity (t/h) | 300 | 450 | 550 | 650 | 1000 | |

| Weighing Scope and Accuracy | Aggregate (kg) | 2400±2% | 4×2000±2% | 4×2200±2% | 4×3600±2% | 4×4500±2% |

| Cement (kg) | 600±1% | 900±1% | 1200±1% | 1800±1% | 2400±1% | |

| Fly Ash (kg) | 200±1% | 300±1% | 400±1% | 600±1% | 800±1% | |

| Water (kg) | 250±1% | 400±1% | 500±1% | 800±1% | 1000±1% | |

| Admixture (kg) | 1×30±1% | 2×30±1% | 2×50±1% | 2×50±1% | 2×80±1% | |

| Total Power (kW) | 92 | 120 | 140 | 190 | 230 | |

| Discharge Height (m) | ≥3.8 | ≥3.8 | ≥3.8 | ≥4 | ≥4 | |

| Note 1. The total power excludes the power of screw conveyor. 2. The hopper quantity and volume can be customized. 3. All above specifications are subject to final products. | ||||||