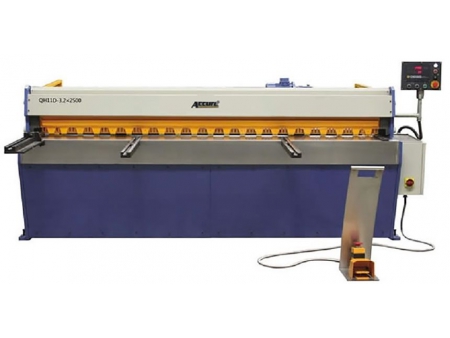

Mechanical Precision Guillotine Shear

Request a Quote

QH11D Series

Whole Structure of Mechanical Precision Guillotine Shear

- With totally European design, streamlined looking, this machine belongs to second generation of mechanical shear. Welded structure: the stress of the welded parts can be eliminated by vibration, so that the cutting is of high accuracy.

- Different from the traditional driving method of mechanical shear, it's one of the most advanced miniature mechanical shear, and enjoys good reputation both at home and abroad.

- The low cutting angle and the inclined shear direction reduce the warpage to a minimum. Blade clearance is easily set by a manually operated quick set device. It is an ideal precision machining machine for metal sheets.

Features

- QH1D series enables high productivity with its ergonomic design.

- Silent running, direct drive system with brake motor, low cost in energy consumption.

- Treadle operating system suitable for both single and repetitive cutting cycles.

- NC controlled back gauge (650mm stroke) by E10s which ensures a higher cutting accuracy.

- The machine passed the European Union CE certification and ISO quality system certification.

Electrical System and Safety Interlock

- Electrical components are imported from Germany, in accordance with international standards, featuring reliable safety, long life, and good anti-interference ability. A radiation unit is fitted in electrical cabinet.

- Protective grill and the safety interlock ensure the operation safety. With a movable single-hand pedal switch, the machine is easy to operate.

- Emergency stops and foot switch are installed on the machine for safety. The grill guard is standard, but the curtain is optional.

Specifications

| Model (QH11D) | Unit | 3.5×1250 | 3.2×1500 | 4×1600 | 3.2×2000 | 2 ×1800 | 2 ×2500 | 3.2×2500 |

| Cutting Thickness | mm | 3.5 | 3.2 | 4 | 3.2 | 2 | 2 | 3.2 |

| Cutting Length | mm | 1250 | 1500 | 1600 | 2000 | 1800 | 2500 | 2500 |

| Cutting Angle | 1°30′ | 1°30′ | 1°45′ | 1°45′ | 1°35′ | 1°45′ | 1°20′ | |

| Number of Stroke | mim-1 | 65 | 55 | 55 | 55 | 55 | 55 | 55 |

| Back Gauge | mm | 0-650 | 0-650 | 0-650 | 0-650 | 0-650 | 0-650 | 0-650 |

| Height of Worktable | mm | 800 | 800 | 800 | 800 | 800 | 800 | 800 |

| Motor Power | Kw | 5.5 | 5.5 | 7.5 | 7.5 | 5.5 | 7.5 | 7.5 |

| Net Weight | Kg | 1450 | 1650 | 2150 | 1800 | 1800 | 2080 | 2200 |

| External Dimensions | Length | 1860 | 2124 | 2650 | 2624 | 2250 | 3124 | 3124 |

| Width | 2210 | 2210 | 2210 | 2210 | 2250 | 2210 | 2210 | |

| Height | 1180 | 1180 | 1250 | 1180 | 1250 | 1180 | 1180 | |

| Working Environment | 1. Power : 380±10%,50HZ | |||||||

| 2. Ambient temperature: 5~40℃(working temperature) | ||||||||

| 3. Ambient humidity: 20~80%RH | ||||||||

| 4. Far from strong shaking and electromagnetism | ||||||||

| 5. No harmful gas and no corrosive gas and dirt-free | ||||||||

| 6. Conforms to the disposition of the machine directive (directive 89/392 CEE), and following amendments (directive 91/368/CEE, 93/44/CEE, 93/68/CEE); | ||||||||

| 7. Conforms to the disposition of the following other directives: directive low voltage (73/23/CEE) and electromagnetic compatibility (89/336/CEE). | ||||||||